Natural graphite/aluminium composite radiating fin and preparation method thereof

A natural graphite and aluminum composite technology, applied in chemical instruments and methods, cooling/ventilation/heating transformation, layered products, etc. heat and other problems, to achieve excellent electromagnetic shielding effect, excellent thermal conductivity, and the effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

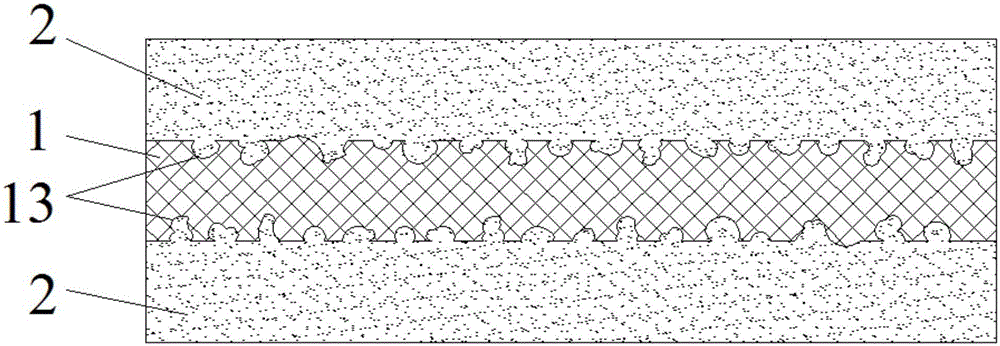

[0025] A preparation method of a natural graphite / aluminum composite heat sink, which is specifically carried out according to the following steps: 1. Double surface treatment of aluminum foil. In contact with air, hands and other handling tools, it is easy to be polluted by grease and salt, so it should be treated with neutral degreasing agent and neutral lotion; 2. The surface can be roughened by anodic oxidation or sandblasting. Rewind after cleaning. At this time, when winding the aluminum foil, it should be light and not too tight, so as not to damage the roughened layer on the surface. The roughened aluminum foil should be cleaned and dried to keep it stable for a period of time. At this time, when winding the aluminum foil, it should be light and not too tight, so as not to damage the roughened layer on the surface; 3. When the expandable graphite particles are heated to 850-1040°C, the graphite particles will expand to more than 60-100 times Worm graphite, the expanded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com