Manhole cover construction method and auxiliary installation device for pavement inspection well

A construction method and installation device technology are applied in the field of manhole cover construction methods and auxiliary installation devices for pavement inspection wells. High-quality and efficient installation and maintenance construction, the effect of reducing pouring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

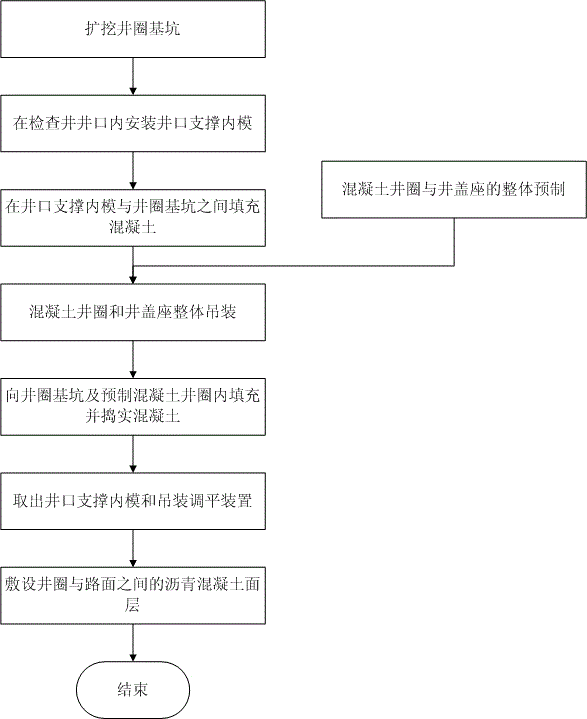

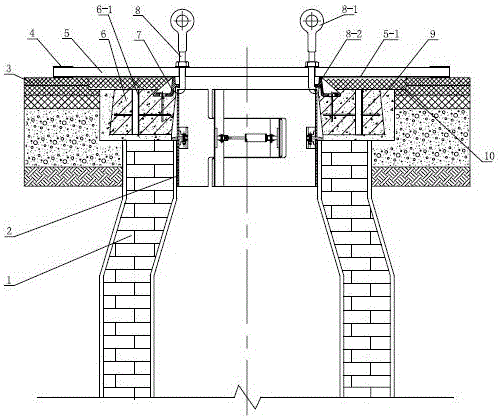

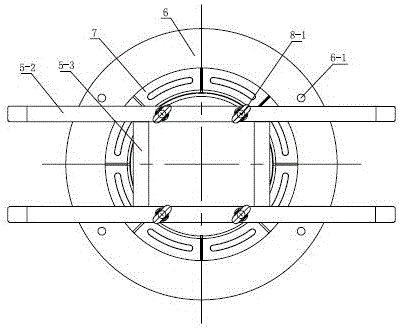

[0031] as attached figure 1 As shown, a kind of well cover construction method of road inspection well of the present embodiment specifically comprises the following steps:

[0032] A. Carry out the overall prefabrication of the concrete well circle and the well cover seat, pre-embed the grout return pipe in the concrete well circle, install the manhole cover seat on the concrete well circle and connect them into one body, expand the area of the manhole cover seat through the concrete well circle, after installation The impact force of the wheels on the well cover is transmitted to the roadbed around the top of the inspection well through the concrete well ring;

[0033] B. The foundation pit of the well circle is expanded around the wellhead of the inspection well, and the diameter of the foundation pit of the well circle is larger than the outer diameter of the inspection well and the diameter of the concrete well circle;

[0034] C. Install a variable-diameter wellhead s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com