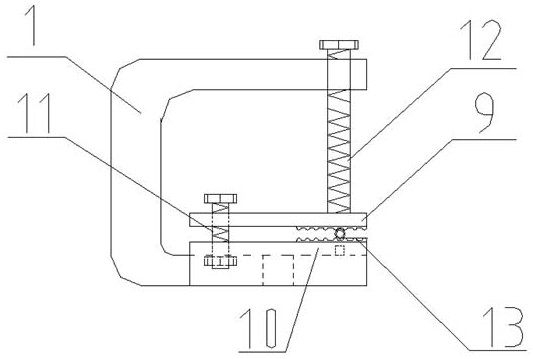

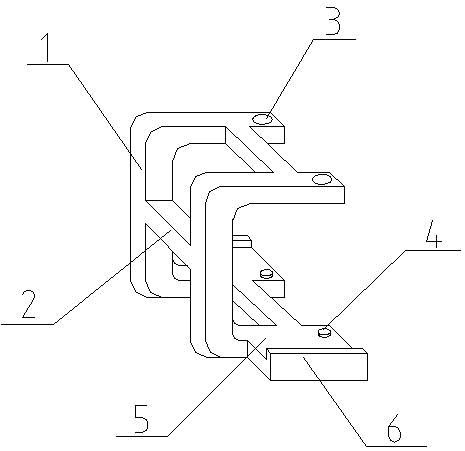

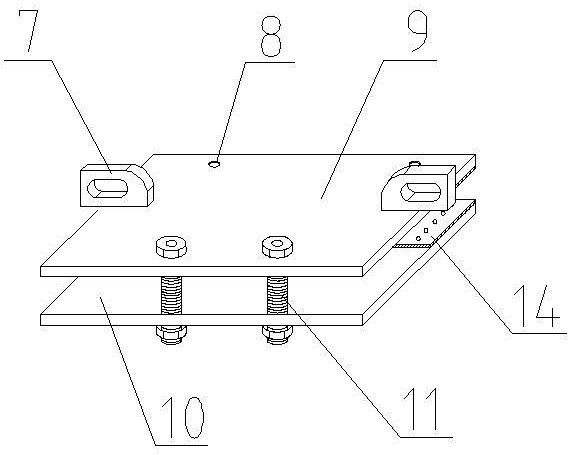

Air-film building outer formwork anchoring traction device and its application method

A technology of traction device and air film construction, which is applied in the direction of construction, building components, building structures, etc., can solve the problems of time-consuming and labor-intensive, labor-intensive human dragging of air film, etc., to achieve improved construction efficiency, uniform force, and easy operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An enterprise builds a large-capacity storage warehouse. The actual perimeter of the annular base is 100m, the total number of diaphragms is 50, the length of the group diaphragm base is 10m, and there are 10 group diaphragms in total. Each group diaphragm consists of 5 Composed of two diaphragms, mark the diaphragms according to 0, 1, 2, 3...49; mark the welding seam position of "0" point on the ring base, and mark on the ring base at intervals of 10m from 0 point Corresponding to the fixed point position of the grouped diaphragm, that is, the fixed point mark of No. 0-9, and the number symbols "0, 1, 2, 3...9" are marked on the ring base as the fixed point mark of the grouped diaphragm ; Every 5 diaphragms are a group of diaphragms, that is, No. 0-4 diaphragms are the first group of diaphragms, No. 5-9 diaphragms are the second group of diaphragms... No. 45-49 diaphragms are Group 10 diaphragm;

[0026] Arrange two parts of operators, the front part is responsible fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com