V-shaped thrusting rod assembly and assembling method thereof

An assembly method and technology of thrust rods, which are applied in the directions of transportation and packaging, cantilevers mounted on pivots, suspensions, etc., can solve problems such as difficult installation of V-shaped thrust rod assemblies, shorten maintenance time, and improve bearing capacity , The effect of simplifying the maintenance process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

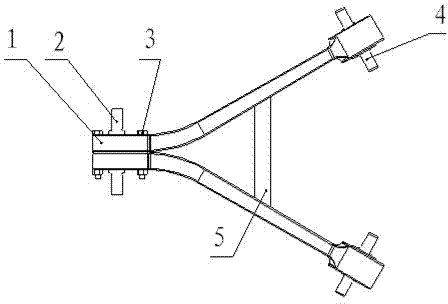

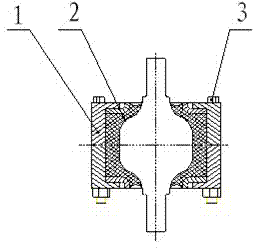

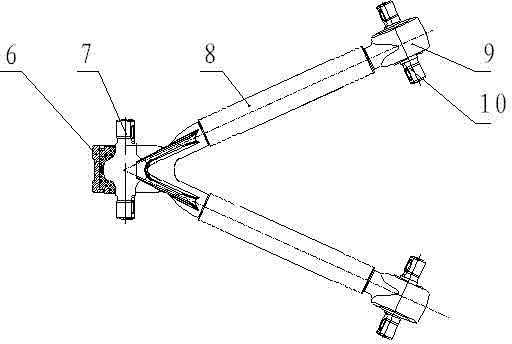

[0023] Figure 1 and figure 2 As shown, the V-shaped thrust rod assembly includes a V-shaped rod mainly composed of two swing arms 1 , an intermediate support beam 5 , a large spherical hinge 2 , a small spherical hinge 4 and bolts and nuts 3 . The two swing arms of the V-shaped bar are split, and the two ends of the two swing arms 1 are provided with inner holes for installing ball hinges, and one end of the two swing arms 1 is respectively press-fitted with a small ball hinge 4 to form a The open free end of the V-shaped rod; the other ends of the two swing arms 1 and the large ball hinge 2 are fixed together by bolts and nuts 3 to form a V-shaped end, and the large ball hinge 2 is locked on the two swing arms by bolts and nuts 3 in the bore of arm 1.

[0024] The large spherical hinge 2 is locked in the inner holes at one end of the two swing arms 1 through bolts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com