Tower crane attachment device

A technology for attachment devices and tower cranes, which is applied to cranes and other directions, can solve problems such as tower crane overturning safety accidents, breakage, tower crane overturning, etc., and achieve the effect of overcoming installation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

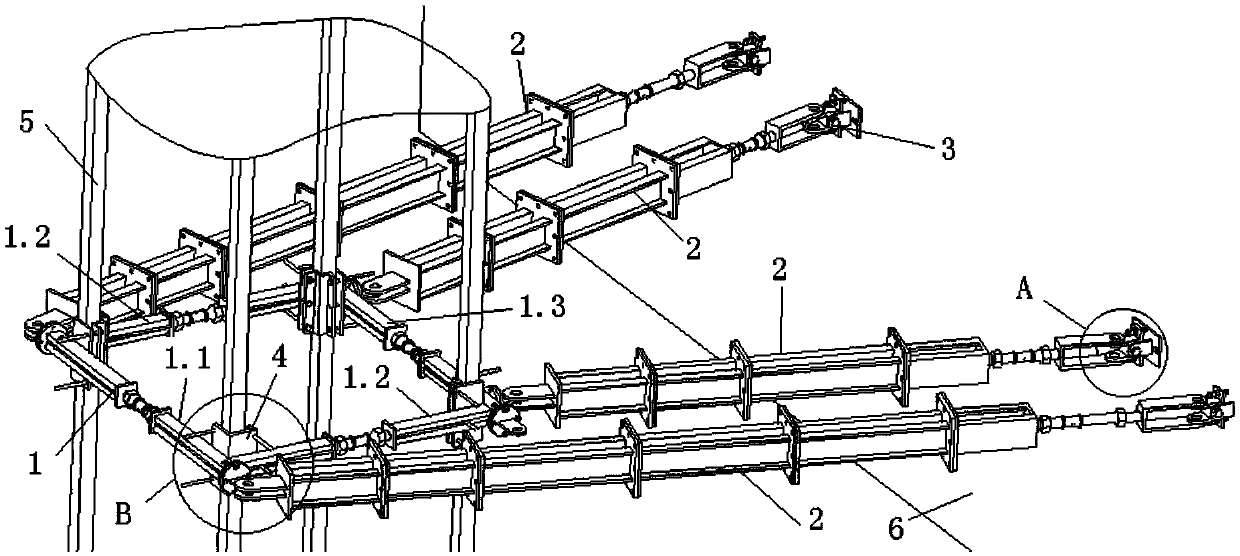

[0050] see Figure 1-11 , a tower crane attachment device, including an attachment frame 1, an adjustable support unit 2 and an adjustable fixing seat 3; the attachment frame is arranged on the tower crane standard section 5, and the adjustable fixing seat 3 is arranged on the fixing surface 6 of the attachment device , the adjustable support single piece connects the attachment frame and the adjustable fixing seat; the installation angle between the attachment frame and the adjustable fixing seat can be adjusted through the cooperation of the attachment frame, the adjustable support single piece and the adjustable fixing seat.

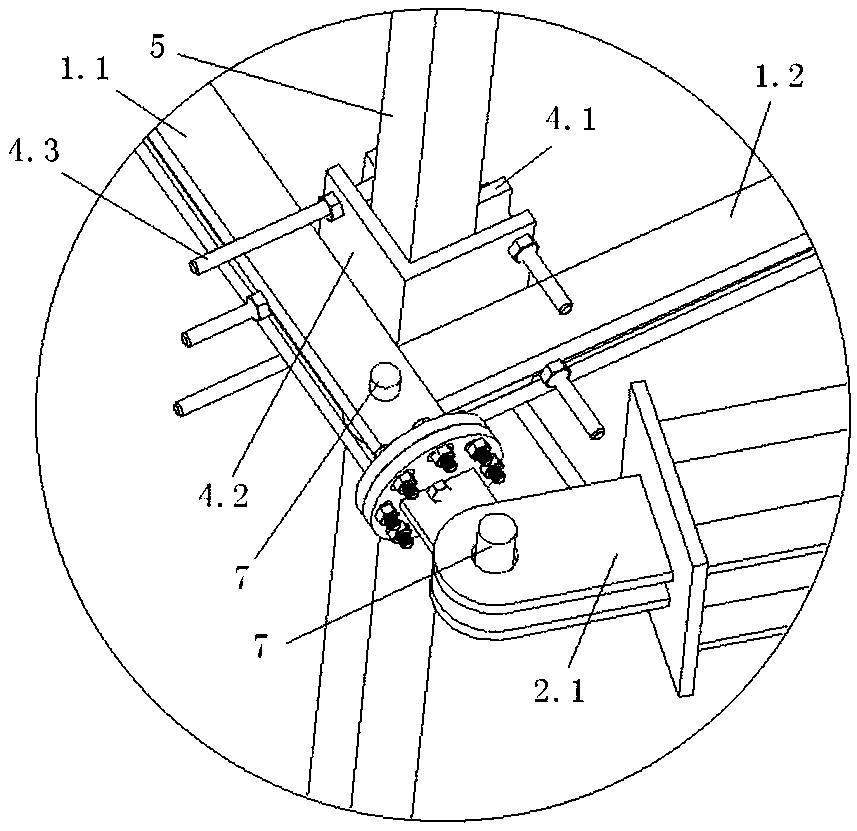

[0051] see figure 2 , the adjustable fixed seat 3 includes a fixed bottom plate 3.1, a rotating base 3.2 and a pin shaft 7 arranged on the fixing surface 6 of the attachment device, and the fixed bottom plate 3.1 and the rotating base 3.2 are provided with a pin shaft for installing the pin shaft 7 hole, the rotating base 3.2 is rotatably connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com