A kind of aerospace defense special fabric and preparation method thereof

An aerospace and national defense technology, applied in the field of fabrics, can solve the problems of poor fiber creep resistance, poor adhesion performance, and low surface polarity, and achieve excellent fire resistance, increased waterproof performance, and soft hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

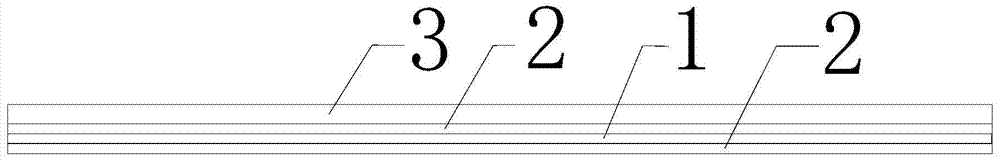

[0051] Such as figure 1 As shown, a special fabric for aerospace and national defense provided by the present invention includes a cloth layer 1, and waterproof layers 2 are arranged on both sides of the cloth layer, and an adhesive layer 3 is arranged on the waterproof layer 2 on one side.

[0052] The aerospace defense special fabric provided by the present invention is provided with a waterproof layer 2 on both sides of the cloth layer 1, and then adds a glue layer 3 on the waterproof layer 2 on one side, and the obtained fabric not only has the performance of the fabric itself, but also through the The double-layer sealing of the fabric layer makes it have super water pressure, which can reach 5000-8000MM, which increases the waterproof performance.

[0053] Aramid 1414 has a golden yellow appearance and looks like a shiny metal thread, but it is actually a liquid crystal polymer composed of rigid long molecules. Because its molecular chains are highly oriented along the ...

Embodiment 2

[0068] A special fabric for aerospace defense, prepared by the following method:

[0069] 10D aramid fiber 1414 is used to weave fabric, and the thickness of the fabric is 0.8mm;

[0070] After cleaning the cloth, dry it or set it at high temperature to make the cloth dry and not wet;

[0071] Immerse the cloth in the aqueous solution of strong waterproofing agent to form a waterproof layer 2 on both sides of the cloth, then dry or set the shape;

[0072] Then calender 2 times;

[0073] On one side of the waterproof layer 2 after calendering, apply a mixture of PU glue and an environmentally friendly flame retardant twice, wherein the content of the environmentally friendly flame retardant in the PU glue is 1%, forming a glue layer 3, the glue Layer 3 has a thickness of 1mm;

[0074] Stay at 170°C for 1.5s for drying after each application of glue, and finally obtain a special aerospace and defense fabric with waterproof layer 2, fabric layer 1, waterproof layer 2 and glue ...

Embodiment 3

[0081] A special fabric for aerospace defense, prepared by the following method:

[0082] Use 50D aramid fiber 1414 to weave into fabric, the thickness of the fabric is 1.5mm;

[0083] After cleaning the cloth, dry it or set it at high temperature to make the cloth dry and not wet;

[0084] Immerse the cloth in the aqueous solution of strong waterproofing agent to form a waterproof layer 2 on both sides of the cloth, then dry or set the shape;

[0085] Then calender 3 times;

[0086] On one side of the waterproof layer 2 after calendering, apply a mixture of PU glue and an environmentally friendly flame retardant twice, wherein the content of the environmentally friendly flame retardant in the PU glue is 2%, forming a glue layer 3, the glue Layer 3 has a thickness of 1.5mm;

[0087] Stay at 180°C for 1.5s for drying after each application of glue, and finally obtain a special aerospace and defense fabric with waterproof layer 2, fabric layer 1, waterproof layer 2 and glue l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com