A kind of absorbable surgical suture and preparation method thereof

A surgical suture and wet spinning technology, which is applied in the fields of surgery, medical science, textiles and papermaking, etc., can solve the problems of complex preparation process, incompatibility of biocompatibility and mechanical properties, etc., achieve smooth surface, avoid dismantling The effect of thread pain, good toughness and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of absorbable surgical suture that the present invention proposes, comprises the following steps:

[0028] S1. According to the solid-liquid ratio of 1.0:100~5.0:100g / ml, the degree of deacetylation is greater than 60%, and the molecular weight is greater than 0.5×10 6 The squid cartilage chitosan is dissolved to obtain the spinning stock solution;

[0029] S2. Wet spinning, drying and stretching the filtered and defoamed spinning stock solution to obtain absorbable surgical sutures.

[0030] Wherein, the preparation of squid cartilage chitosan in step S1 comprises:

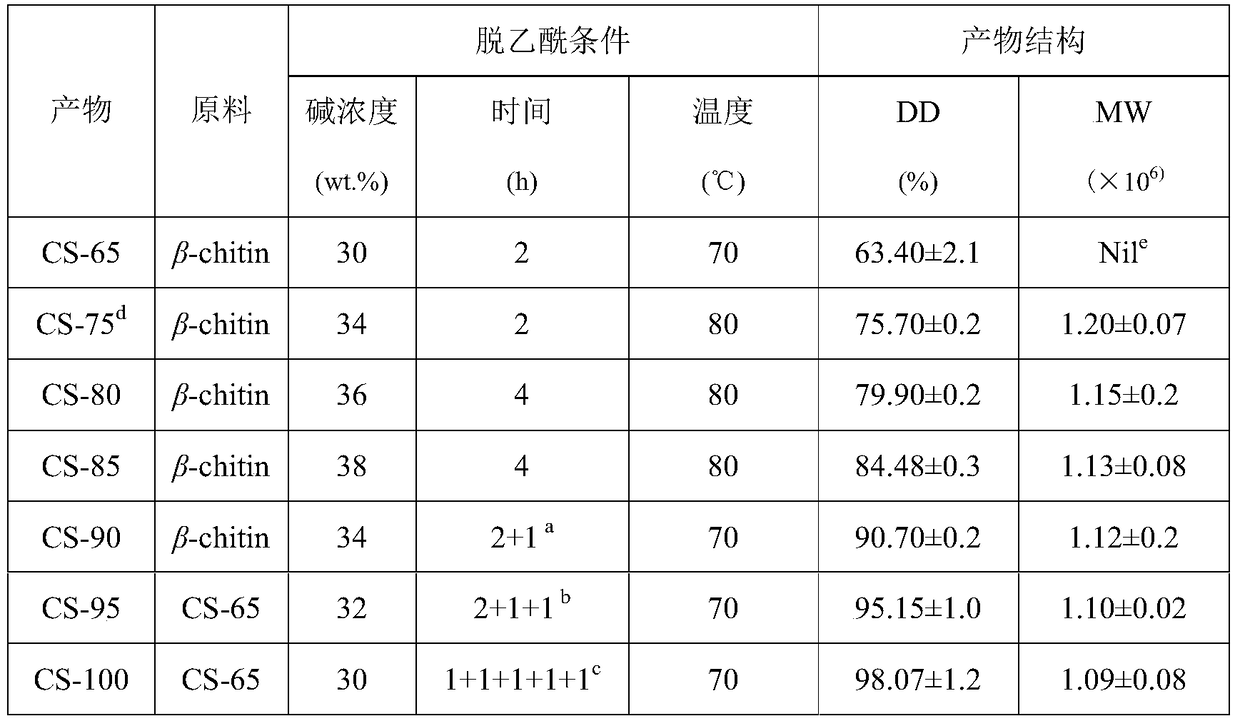

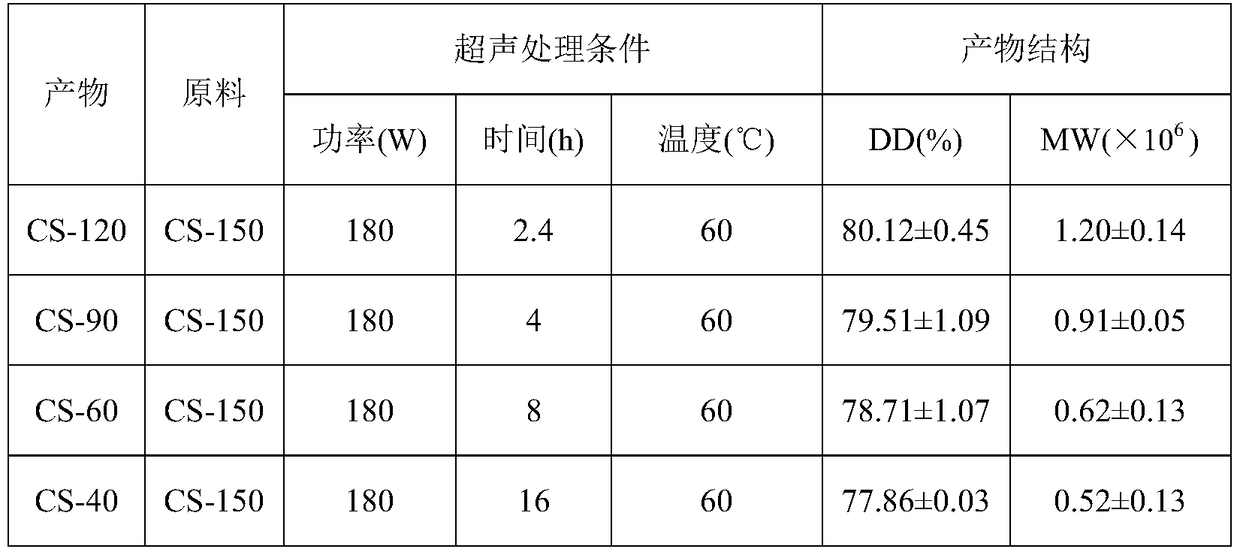

[0031] S11. Dissolve squid cartilage β-chitin or squid cartilage chitosan in a NaOH solution with a mass percent concentration of 30% to 40% according to a solid-liquid ratio of 5.0:100 to 25:100 g / ml, at 50 to 80 After stirring at ℃ for 1-6 hours, filter to obtain the filter residue;

[0032] S12, washing the filter residue obtained in step S11 until neutral and then drying...

Embodiment 1

[0055] A kind of preparation method of absorbable surgical suture that the present invention proposes, comprises the following steps:

[0056] S1, 2.0g squid cartilage chitosan (DD=75.70%, MW=1.20×10 6 ) powder was dissolved in 50ml of acetic acid solution with a mass percentage concentration of 2%, stirred for 2 hours under the action of a magnetic stirrer, and after being completely dissolved, the spinning stock solution was obtained;

[0057] S2. After filtering and defoaming the spinning stock solution, input the spinneret with an inner diameter of 0.8mm through a metering pump, and squeeze the spinning stock solution into the coagulation bath with a pressure of 40N to obtain chitosan monofilament; wherein, each group of the coagulation bath The mass percent of points comprises: 4% sodium hydroxide, 2% ethanol, and the rest are deionized water;

[0058] S3. Chitosan monofilaments were soaked in deionized water and washed until neutral, then stretched 10N at room temperatu...

Embodiment 2

[0064] A kind of preparation method of absorbable surgical suture that the present invention proposes, comprises the following steps:

[0065] S1, 2.2g squid cartilage chitosan (DD=79.99%, MW=1.15×10 6 ) powder was dissolved in 50ml of acetic acid solution with a mass percentage concentration of 2%, stirred for 2 hours under the action of a magnetic stirrer, and after being completely dissolved, the spinning stock solution was obtained;

[0066] S2. After filtering and defoaming the spinning stock solution, input the spinneret with an inner diameter of 0.5mm through a metering pump, and squeeze the spinning stock solution into the coagulation bath with a pressure of 60N to obtain chitosan monofilament; wherein, each group of the coagulation bath The mass percent of points comprises: sodium hydroxide 6%, ethanol 1%, all the other are deionized water;

[0067] S3. Chitosan monofilaments were soaked in deionized water and washed until neutral, then stretched 10N at room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com