Preparing method and application of high-strength soft magnetic composite material

A soft magnetic composite material, high-strength technology, applied in the direction of inorganic material magnetism, mechanical equipment, bearings, etc., can solve the problems of low mechanical strength, large eddy current loss, low magnetic performance, etc. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for preparing a high-strength soft magnetic composite material, comprising the following steps:

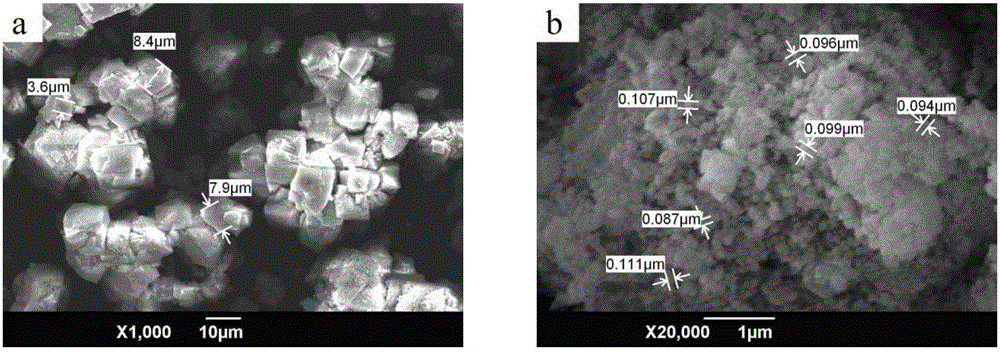

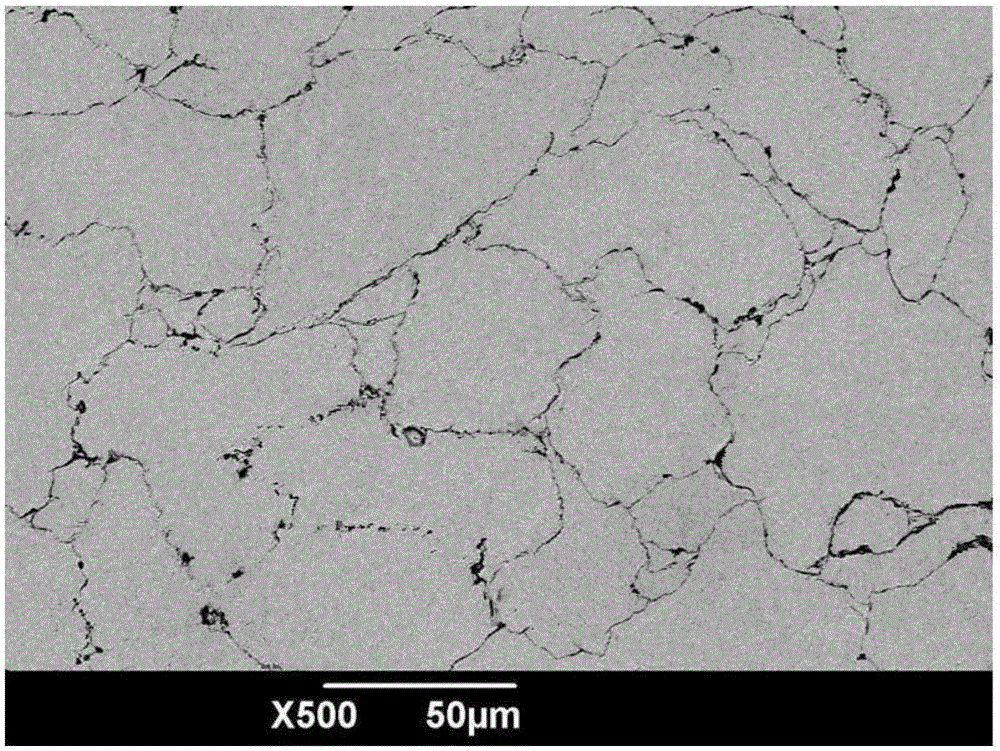

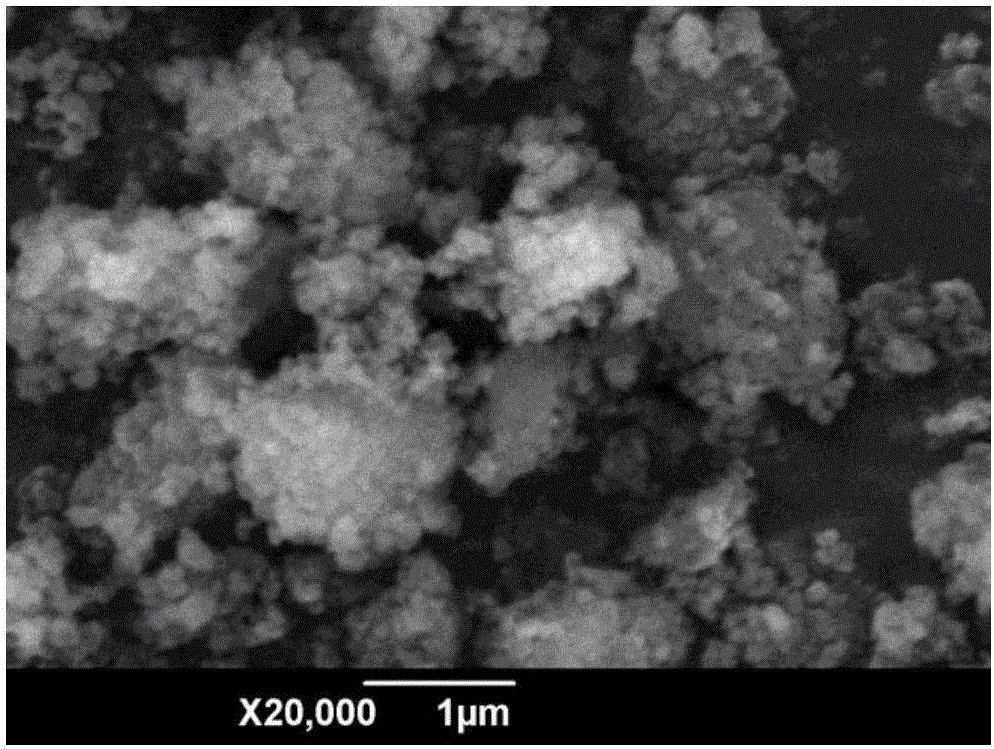

[0050] Step 1, processing iron powder

[0051] Prepare 1000g of pure iron powder first, requiring the purity of the pure iron powder to be 99.99wt%, and the iron particle size to be 60-120 μm; then dissolve the pure iron powder in an acetone solution with a concentration of 99.9wt% for degreasing, and use Stir with a spiral stirrer for 10 minutes and repeat 3 times to achieve the purpose of degreasing; then filter out the iron powder, wash the iron powder and wait for the acetone to volatilize completely, then place it in a vacuum furnace to dry at a temperature of 60°C;

[0052] Step 2, passivating iron powder

[0053] The dried iron powder and NaNO 2 The alkaline solution was mixed and stirred for 30min at a stirring speed of 300r / min, NaNO 2 The pH value of the alkaline solution before mixing is 8.0, and the pH value of the mixture rises during the stirring p...

Embodiment 2

[0066] A method for preparing a high-strength soft magnetic composite material, comprising the following steps:

[0067] Step 1, processing iron powder

[0068] Prepare 1000g of pure iron powder first, requiring the purity of the pure iron powder to be 99.99wt%, and the iron particle size to be 60-120 μm; then dissolve the pure iron powder in an acetone solution with a concentration of 99.9wt% for degreasing, and use Stir with a spiral stirrer for 12 minutes and repeat 3 times to achieve the purpose of degreasing; then filter out the iron powder, wash the iron powder and wait for the acetone to volatilize completely, then place it in a vacuum furnace and dry it at a temperature of 58°C;

[0069] Step 2, passivating iron powder

[0070] The dried iron powder and NaNO 2 Alkaline solution mixed, and stirred at a stirring speed of 300r / min for 20min, NaNO 2 The pH value of the alkaline solution before mixing is 8.0, and the pH value of the mixture rises during the stirring proc...

Embodiment 3

[0083] A method for preparing a high-strength soft magnetic composite material, comprising the following steps:

[0084] Step 1, processing iron powder

[0085] Prepare 1000g of pure iron powder first, requiring the purity of the pure iron powder to be 99.99wt%, and the iron particle size to be 60-120 μm; then dissolve the pure iron powder in an acetone solution with a concentration of 99.9wt% for degreasing, and use Stir with a spiral stirrer for 15 minutes and repeat 3 times to achieve the purpose of degreasing; then filter out the iron powder, wash the iron powder and wait for the acetone to evaporate completely, then place it in a vacuum furnace to dry at a temperature of 50°C;

[0086] Step 2, passivating iron powder

[0087] The dried iron powder and NaNO 2 mixed alkaline solution, and stirred at a stirring speed of 300r / min for 15min, NaNO 2 The pH value of the alkaline solution before mixing is 8.0, and the pH value of the mixture rises during the stirring process a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com