Multi-stage a/o-mbr treatment method of oil shale retort wastewater

A segmented water inlet and treatment method technology, applied in the field of sewage treatment, can solve the problems of high treatment cost, unstable treatment effect, low removal rate, etc., and achieve the goal of reducing the reflux ratio of mixed liquid, saving aeration cost, and reducing dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

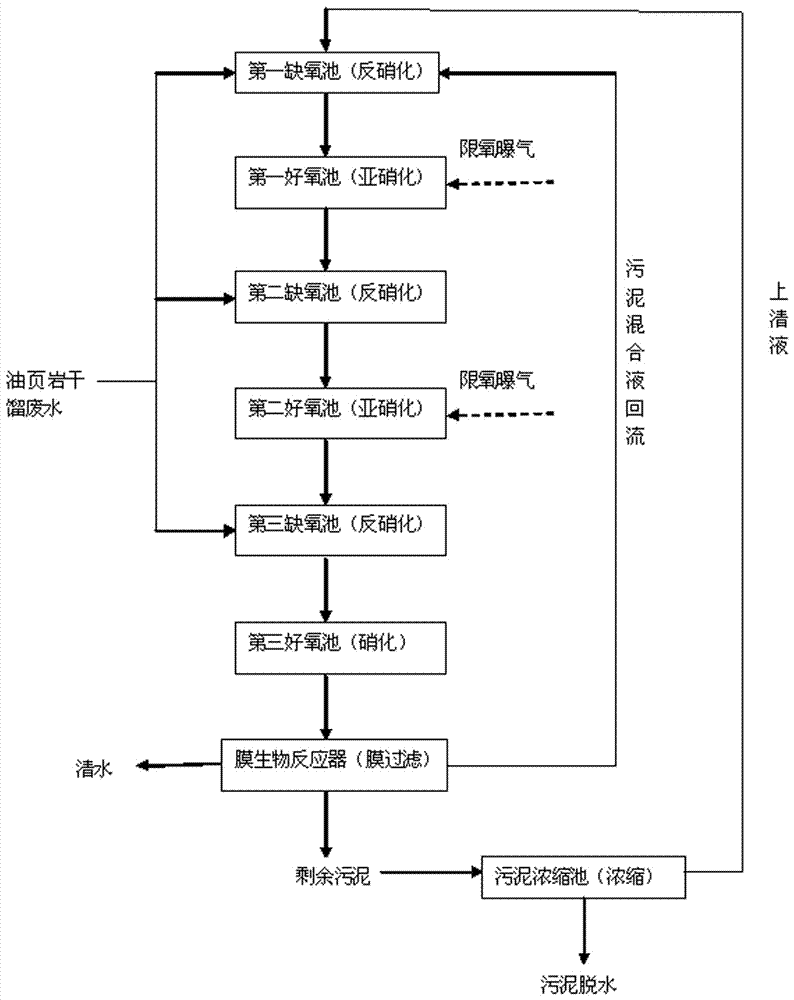

[0031] The pretreated oil shale retort wastewater is introduced into the multi-stage A / O-MBR treatment system with water inflow; the multi-stage A / O-MBR treatment system with water inflow is composed of the first anoxic pool, the first aerobic pool, The second anoxic pool, the second aerobic pool, the third anoxic pool, the third aerobic pool and the membrane bioreactor are connected in series, and each anoxic pool is equipped with a stirring device or a submersible propeller. The tanks are equipped with aeration devices, and the membrane bioreactor is connected to the first anoxic tank through the return pipe; the oil shale carbonization wastewater is divided into the first part, the second part and the third part, and enters the first anoxic tank, the second part and the third part respectively. The second anoxic pond and the third anoxic pond; wherein the first part accounts for 35% of the total volume of all oil shale retort wastewater, and the second part accounts for 35% ...

Embodiment 2

[0043] Method is with embodiment 1, and difference is:

[0044] (1) The ammonia nitrogen concentration of pretreated oil shale dry distillation wastewater is 2000mg / L, the total nitrogen content is 2100mg / L, and the COD concentration is 1900mg / L; the activated sludge concentration in each aerobic pool and anoxic pool is 2000mg / L; The first part accounts for 45% of the total volume of all oil shale retort wastewater, and the second part accounts for 30% of the total volume of all oil shale retort wastewater;

[0045] (2) The temperature during the nitrification reaction is 10°C;

[0046] (3) Control the reflux ratio of the whole system to 300%;

[0047] (4) The ammonia nitrogen concentration of the discharged clear water is 4.8mg / L, the total nitrogen content is 170mg / L, and the COD is 240mg / L;

[0048] (5)V 1 The selected value is 0.08, the total hydraulic retention time of the anoxic pool is t 1 =24×(2100-200) / (3000×V 1 ), t 1 =190 hours; the hydraulic retention time t ...

Embodiment 3

[0051] Method is with embodiment 1, and difference is:

[0052] (1) The ammonia nitrogen concentration of pretreated oil shale dry distillation wastewater is 3000mg / L, the total nitrogen content is 3100mg / L, and the COD concentration is 4000mg / L; the activated sludge concentration in each aerobic pool and anoxic pool is 5000mg / L; The first part accounts for 45% of the total volume of all oil shale retort wastewater, and the second part accounts for 35% of the total volume of all oil shale retort wastewater;

[0053] (2) The temperature during the nitrification reaction is 30°C;

[0054] (3) Control the reflux ratio of the whole system to 400%;

[0055] (4) The ammonia nitrogen concentration of the discharged clear water is 8.2mg / L, the total nitrogen content is 230mg / L, and the COD is 260mg / L;

[0056] (5)V 1 The selected value is 0.2, the total hydraulic retention time of the anoxic pool is t 1 =24×(3100-200) / (5000×V 1 ), t 1 =70 hours; the hydraulic retention time t of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com