A kind of preparation method and application of rice granular nano-magnetic iron oxide

A nano-magnetic and iron oxide technology, which is applied in the preparation of rice granular nano-magnetic iron oxides and iron oxides, achieving the effects of low production cost, narrow product distribution, and simple and feasible methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Iron oxyhydroxide was prepared by hydrolysis.

[0027] Anhydrous FeCl 3 and cetyltrimethylammonium chloride were dissolved in 30 mL deoxygenated water, stirred to obtain a transparent solution, and FeCl 3 The concentration of cetyltrimethylammonium chloride is 0.1 mol / L, and the concentration of cetyltrimethylammonium chloride is 0.05 mol / L. Then the two solutions were mixed, stirred magnetically at 40°C for 12 hours, and the reaction was completed, the resulting reaction solution was centrifuged, the supernatant was removed, and then washed with deoxygenated water three times, then washed with absolute ethanol, centrifuged, and kept overnight at 50°C After drying, the yellow iron oxyhydroxide with a rice grain-like aspect ratio of 4:1 was obtained at last.

[0028] The iron oxyhydroxide obtained above was burned in vacuum at 200°C for 4 hours to obtain Fe with a red rice grain aspect ratio of 4:1. 2 o 3 Nanoparticles.

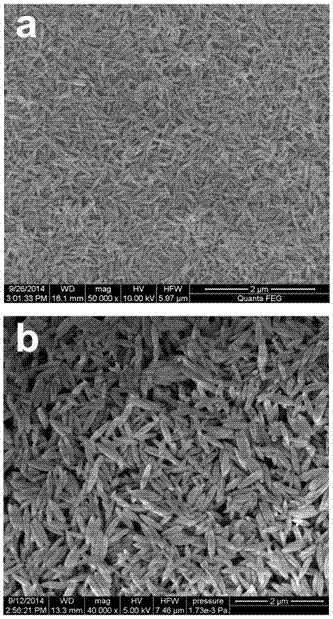

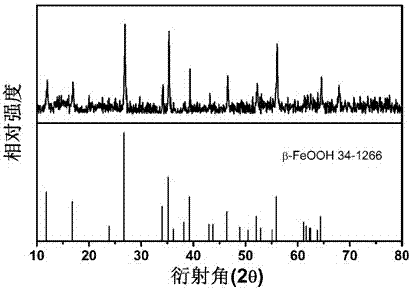

[0029] figure 1 It is a scanning electron m...

Embodiment 2

[0031] Iron oxyhydroxide was prepared by hydrolysis.

[0032] Will Fe 2 (SO 4 ) 3and sodium dodecylbenzenesulfonate were dissolved in 30 mL deoxygenated water, and stirred to obtain a transparent solution, and Fe 2 (SO 4 ) 3 The concentration of sodium dodecylbenzenesulfonate is 0.2 mol / L, and the concentration of sodium dodecylbenzenesulfonate is 0.15 mol / L. Then the two solutions were mixed and magnetically stirred at 80° C. for 4 h. After the reaction is completed, the obtained reaction liquid is centrifuged, the supernatant is removed, and the product is washed three times with deoxygenated water, then washed with absolute ethanol, centrifuged, and dried overnight at 50°C, and finally the rice grain with an aspect ratio of 8 is obtained. :1 yellow iron oxyhydroxide.

[0033] Burn the iron oxyhydroxide obtained above at 300°C for 3 hours in a vacuum to obtain Fe with a red rice grain aspect ratio of 8:1. 2 o 3 Nanoparticles.

Embodiment 3

[0035] Iron oxyhydroxide was prepared by hydrolysis.

[0036] FeCl 3 ·6H 2 O and dodecyltrimethylammonium bromide were dissolved in 30 mL deoxygenated water, respectively, and stirred to obtain a transparent solution to obtain FeCl 3 ·6H 2 The concentration of O was 0.1 mol / L, and the concentration of dodecyltrimethylammonium bromide was 0.2 mol / L. Then the two solutions were mixed and magnetically stirred at 50° C. for 10 h. After the reaction is completed, the resulting reaction solution is centrifuged, the supernatant is removed, and the product is washed three times with deoxygenated water, then washed with absolute ethanol, centrifuged, and dried overnight at 50° C., finally obtaining a yellow rice grain with an aspect ratio of 6:1 iron oxyhydroxide.

[0037] The iron oxyhydroxide obtained above was burned in hydrogen at 400°C for 2 hours to obtain black rice-like Fe with an aspect ratio of 6:1. 3 o 4 Nanoparticles.

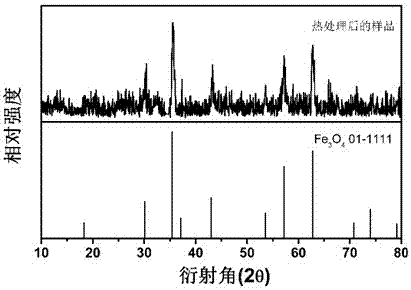

[0038] image 3 It is the Fe prepared in Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com