Alginate oligomer dairy capable of reducing cholesterol

A technology of fucoidan oligosaccharides and dairy products, applied in dairy products, milk preparations, applications, etc., can solve problems such as difficult to dissolve, large molecular weight, high viscosity, etc., and achieve the effect of inhibiting absorption, inhibiting reaction, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

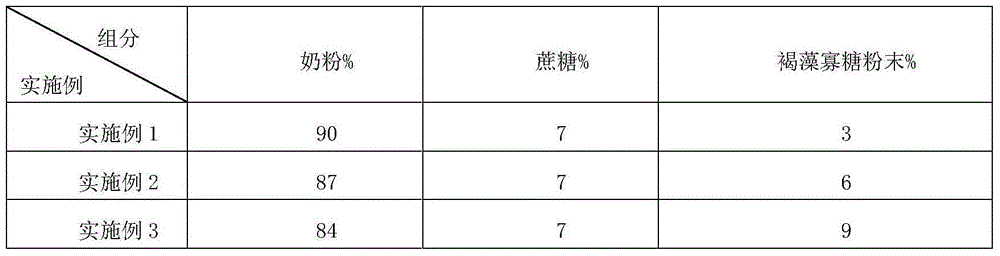

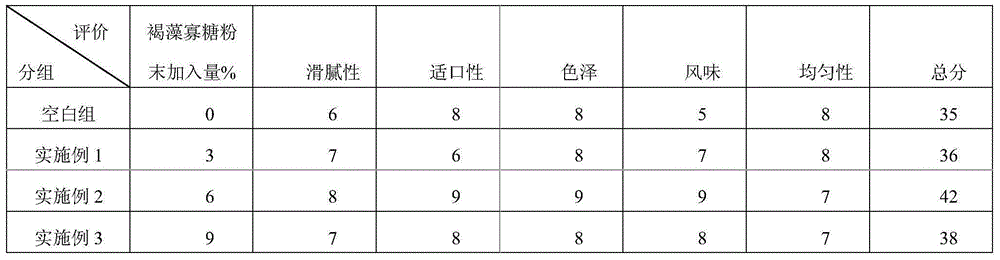

Examples

Embodiment 1

[0023] 1. Preparation of alginate lyase

[0024] (1) To 1000 mL of seawater, add 50 grams of kelp powder and 10 grams of potassium nitrate, adjust the initial pH to 7.0 with NaOH aqueous solution, sterilize and cool to room temperature. (2) Add 100 mL of strain, culture with shaking at 25°C for 48 hours, and centrifuge to get the supernatant. (3), add 10 grams of polyetherimide, and centrifuge to remove the flocculent precipitate. (4) The supernatant is eluted on a Sepharose chromatographic column to obtain alginate lyase.

[0025] 2. Preparation of fucoidan oligosaccharides

[0026] (1) Dissolution of alginate: Dissolve 20 grams of alginate in 2000 mL of distilled water to form a 1% alginate solution, heat and stir at 60° C. on a magnetic stirrer to completely dissolve it. (2) Enzymatic hydrolysis of alginate: add 10 mL of alginate lyase into the dissolved alginate solution, and react on a magnetic stirrer at 60° C. for 12 hours. (3) Inactivation of the enzymolysis soluti...

Embodiment 2

[0043] The specific implementation is as follows:

[0044] 1. Preparation of alginate lyase

[0045] (1) To 1000 mL of seawater, add 50 grams of kelp powder and 10 grams of potassium nitrate, adjust the initial pH to 7.0 with NaOH aqueous solution, sterilize and cool to room temperature. (2) Add 100 mL of strain, culture with shaking at 25°C for 48 hours, and centrifuge to get the supernatant. (3), add 10 grams of polyetherimide, and centrifuge to remove the flocculent precipitate. (4) The supernatant is eluted on a Sepharose chromatographic column to obtain alginate lyase.

[0046] 2. Preparation of fucoidan oligosaccharides

[0047] (1) Dissolution of alginate: Dissolve 20 grams of alginate in 2000 mL of distilled water to form a 1% alginate solution, heat and stir at 60° C. on a magnetic stirrer to completely dissolve it. (2) Enzymatic hydrolysis of alginate: add 10 mL of alginate lyase into the dissolved alginate solution, and react on a magnetic stirrer at 60° C. for ...

Embodiment 3

[0064] The specific implementation is as follows:

[0065] One, the preparation of alginate lyase:

[0066] (1) Seawater 1000mL, add 50 grams of kelp powder and 10 grams of potassium nitrate, adjust the initial pH to 7.0 with NaOH aqueous solution, sterilize and cool to room temperature. (2) Add 100mL strains, culture with shaking at 25°C for 48h, and centrifuge to get the supernatant. (3) Add 10 grams of polyetherimide, and centrifuge to remove the flocculent precipitate. (4) The supernatant is eluted on a Sepharose chromatographic column to obtain alginate lyase.

[0067] 2. Preparation of fucoidan oligosaccharides:

[0068] (1) Dissolution of alginate: Dissolve 20 grams of alginate in 2000 mL of distilled water to form a 1% alginate solution, and heat and stir at 60° C. on a magnetic stirrer to completely dissolve it. (2) Enzymatic hydrolysis of alginate: Add 10 mL of alginate lyase into the dissolved alginate solution, and react on a magnetic stirrer at 60° C. for 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com