Acrylic resin film

An acrylic resin, acrylic technology, applied in the field of acrylic resin film, can solve the problems of poor resistance, high cost, poor water resistance, etc., and achieve the effects of excellent resistance, low manufacturing cost, chemical resistance and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

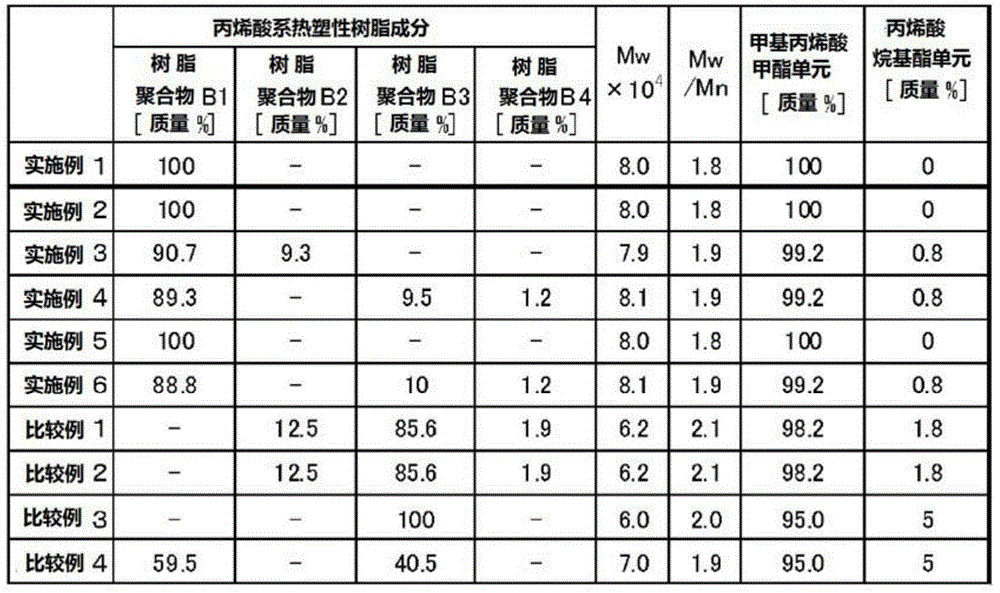

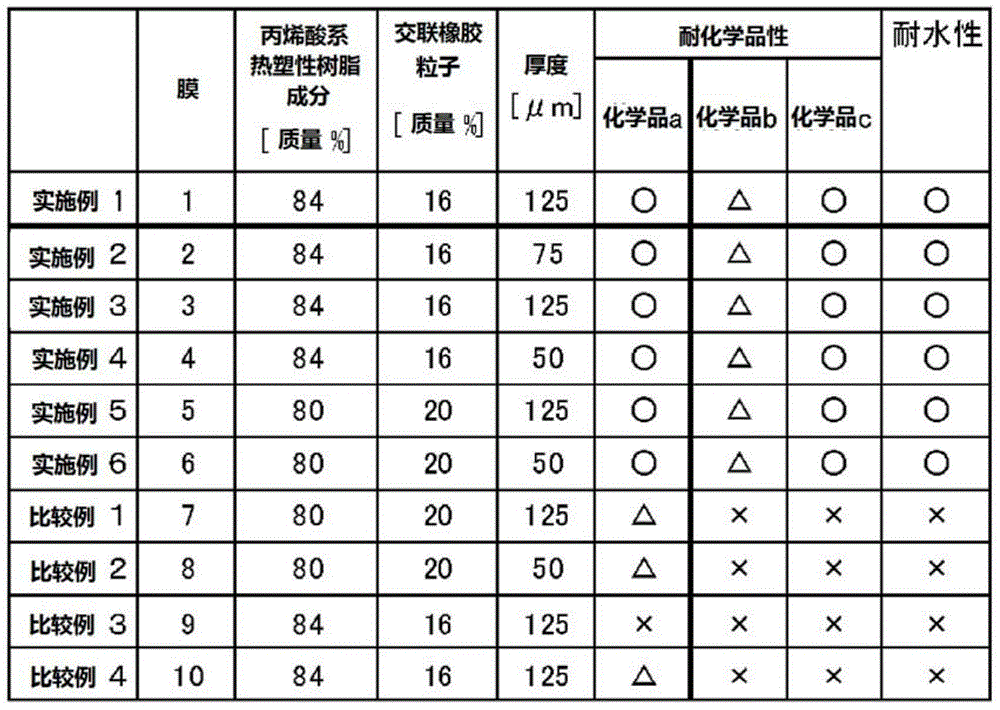

Examples

Embodiment

[0156] The present invention will be described more specifically by showing Examples and Comparative Examples below, but the present invention is not limited by them. In addition, the measurement or evaluation of the physical property value in the Example and the comparative example was performed by the following method.

[0157] (average particle diameter of cross-linked rubber particles)

[0158] The measurement was performed using a laser diffraction / scattering type particle size distribution analyzer LA-910 manufactured by HORIBA CO., LTD.

[0159] (Weight average molecular weight (Mw), molecular weight distribution (Mw / Mn) of acrylic thermoplastic resin)

[0160] In the high-performance liquid chromatography apparatus, "GPC-802", "HSG-30", "HSG-50" manufactured by Shimadzu Corporation and Showa Denko Co., Ltd. were used as columns for gel permeation chromatography (GPC). "ShodexA-806" was used after being connected in series, a differential refractive index detector was...

reference example 1

[0183] [Manufacture of Crosslinked Rubber Particles (A1)]

[0184] (1) Add 1050 parts by mass of ion-exchanged water, 0.3 parts by mass of polyoxyethylene tridecyl ether sodium acetate and carbonic acid Sodium was 0.7 parts by mass, and the inside of the reactor was fully replaced with nitrogen. Then the internal temperature was adjusted to 80°C. 0.25 parts by mass of potassium persulfate was thrown in there, and stirred for 5 minutes. There, 245 parts by mass of a monomer mixture consisting of 95.4 mass % of methyl methacrylate, 4.4 mass % of methyl acrylate, and 0.2 mass % of allyl methacrylate was continuously added dropwise thereto over 60 minutes. After the dropwise addition was completed, a polymerization reaction was carried out for 30 minutes so that the polymerization conversion rate became 98% or more.

[0185] (2) Then, 0.32 parts by mass of potassium persulfate was injected into the same reactor, and stirred for 5 minutes. Then, 315 parts by mass of a monomer ...

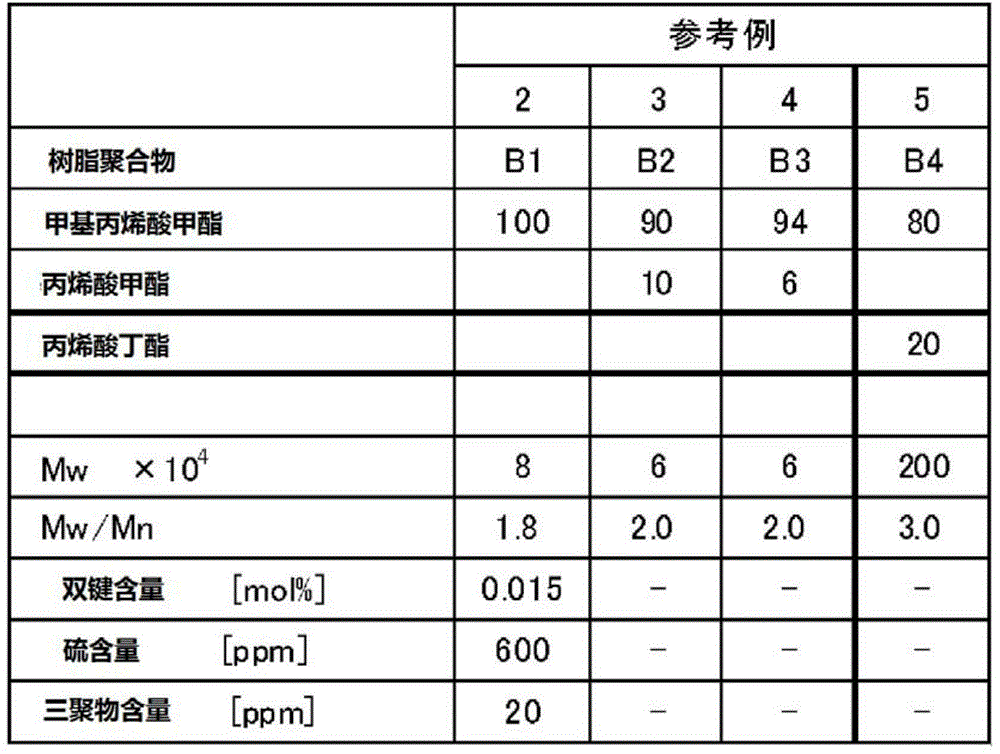

reference example 2

[0187] [Manufacture of Resin Polymer (B1)]

[0188] A resin polymer (B1) having a weight average molecular weight of 80,000 was produced by bulk polymerizing a monomer composed of 100% by mass of methyl methacrylate. Table 2 shows the physical property values and the like of the resin polymer (B1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com