Foamed nickel-supported cobalt acid ferrous submicron tube electrode material and preparation method thereof

A technology for supporting ferrous cobaltate and submicron tubes, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problem of mechanical stability being difficult to meet multiple cycles of charge and discharge, and achieve good industrial application. Prospect, easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Submicron Tubular FeCo 2 o 4 Supercapacitor material: Dissolve 0.40g ferric nitrate nonahydrate and 0.58g cobalt nitrate hexahydrate in 50mL deionized water; put the mixed solution and nickel foam in a 250mL three-neck Erlenmeyer flask, and heat the oil bath to 80°C ; Then, after dissolving 1.51g oxalic acid in 50mL deionized water, slowly add it dropwise into the three-necked Erlenmeyer flask of the above system, under the mechanical stirring at a speed of 25-40r / min, keep the constant temperature oil bath for 2h; after the reaction is complete , cooled naturally to room temperature, took out the nickel foam loaded with the precursor, and washed it with deionized water and absolute ethanol several times; freeze-dried for 12 hours; heated to 400°C at a heating rate of 5°C / min, , constant temperature for 2h to obtain the final product.

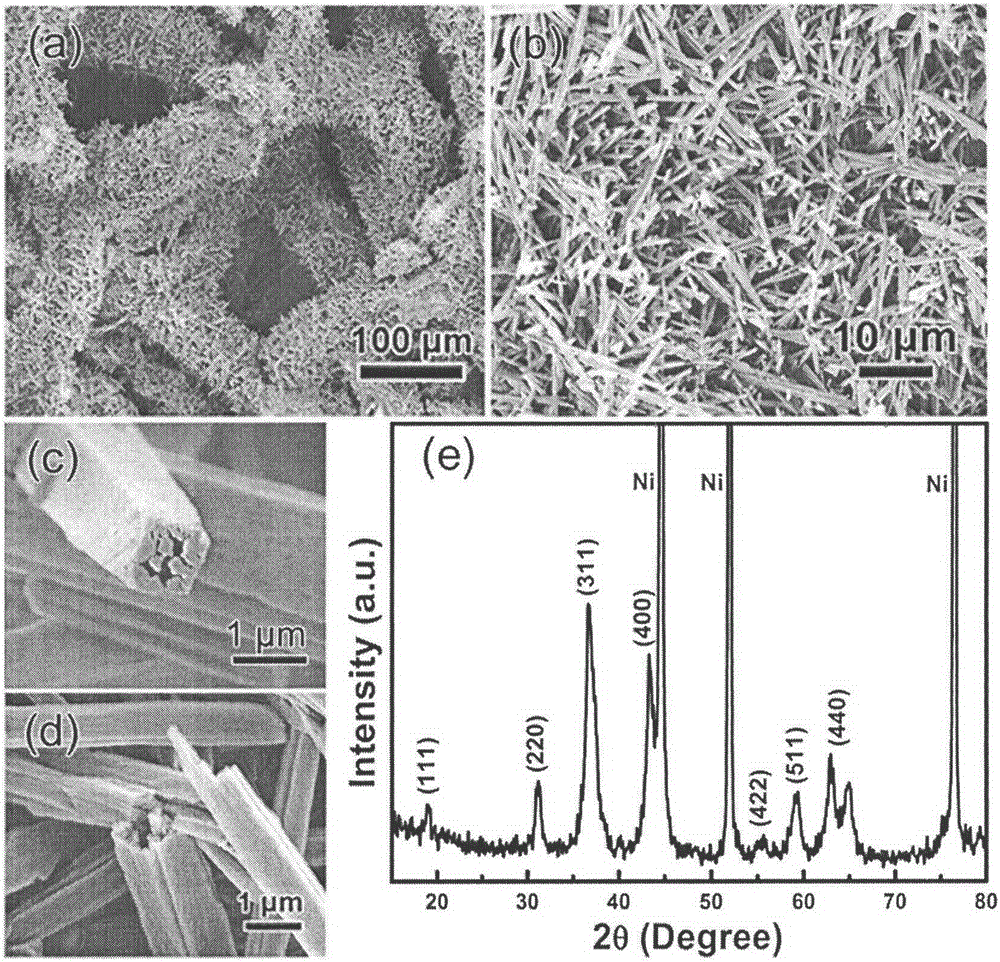

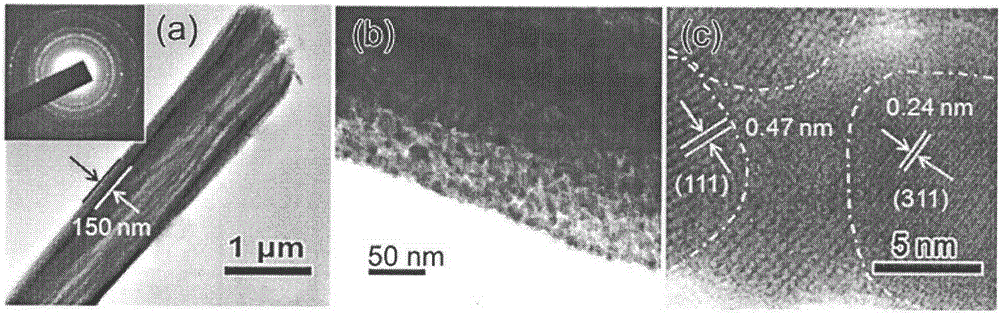

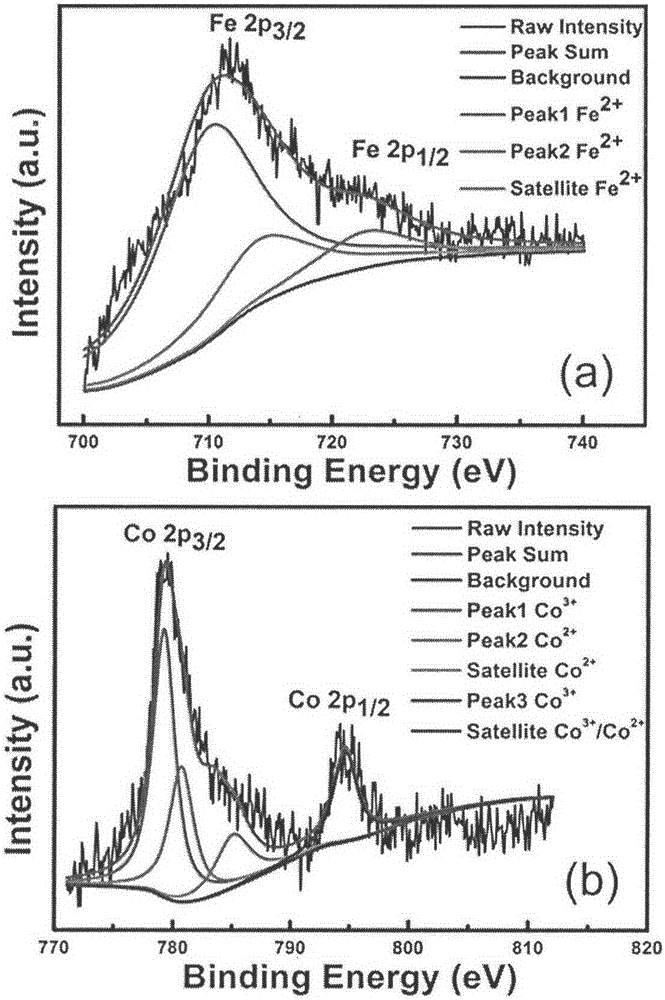

[0029] figure 1 a is a low power SEM image of the product prepared in Example 1. The product is evenly distributed on the nickel fo...

Embodiment 2

[0033] Fe 3+ 、Co 2+ , the concentration of oxalic acid was 1.3mM, 2.5mM and 15mM respectively, and other conditions were the same as in Example 1.

Embodiment 3

[0035] Fe 3+ 、Co 2+ and the concentration of oxalic acid are respectively 5mM, 10mM and 60mM, and other conditions are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com