Basic structural units of acoustic metamaterials and their composite structures and assembly methods

An acoustic metamaterial and basic structure technology, applied in the field of materials, can solve the problems such as the inability to effectively compensate for the total reflection peak sound insulation valley, the sound insulation effect is not as good as that of a uniform material, and the total reflection peak frequency band is narrow, etc., to achieve excellent noise reduction effect, small noise. The cost of areal density and the effect of less processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

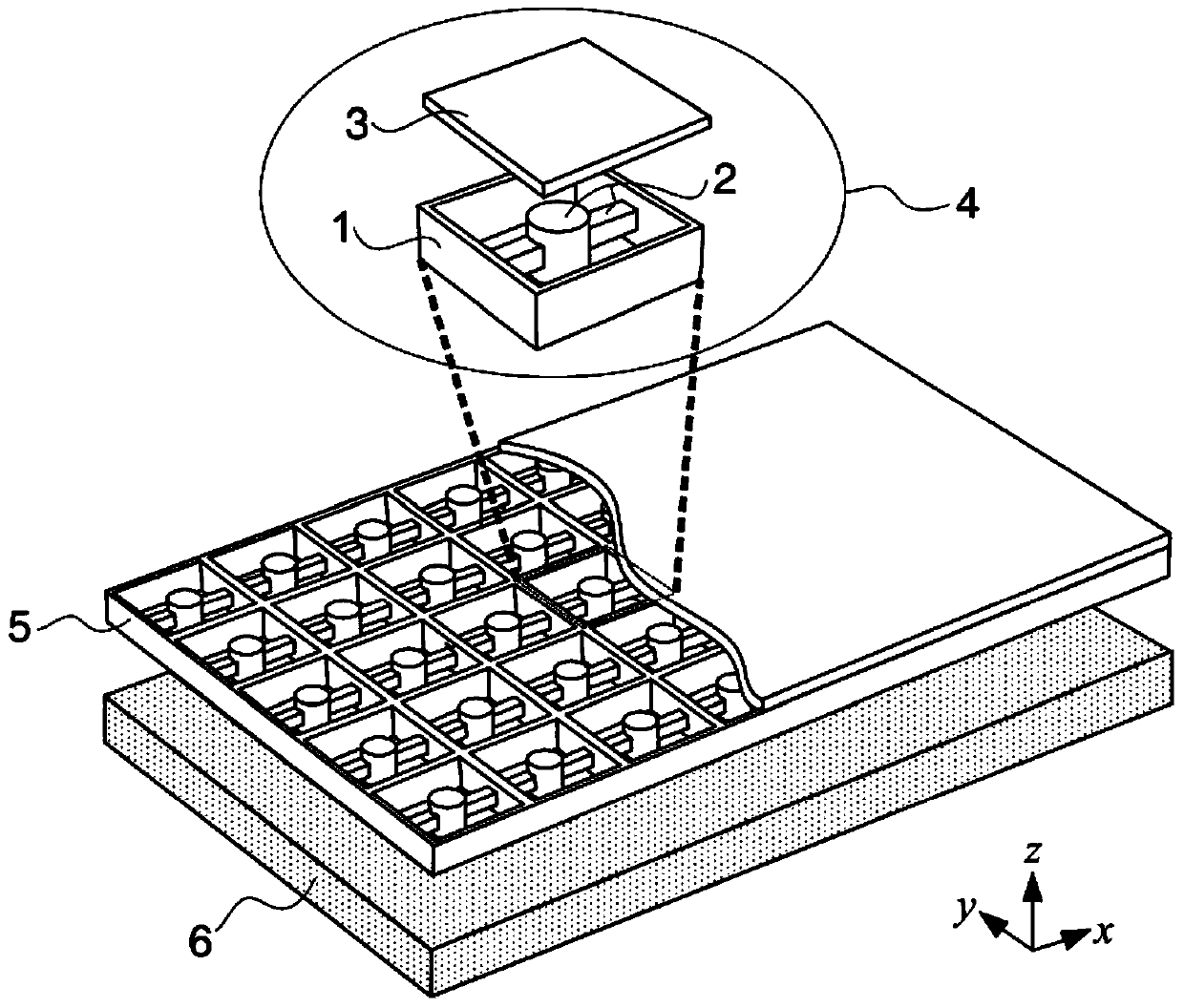

[0093] Example 1 Preparation and Performance Measurement of Basic Structural Units of Acoustic Metamaterials

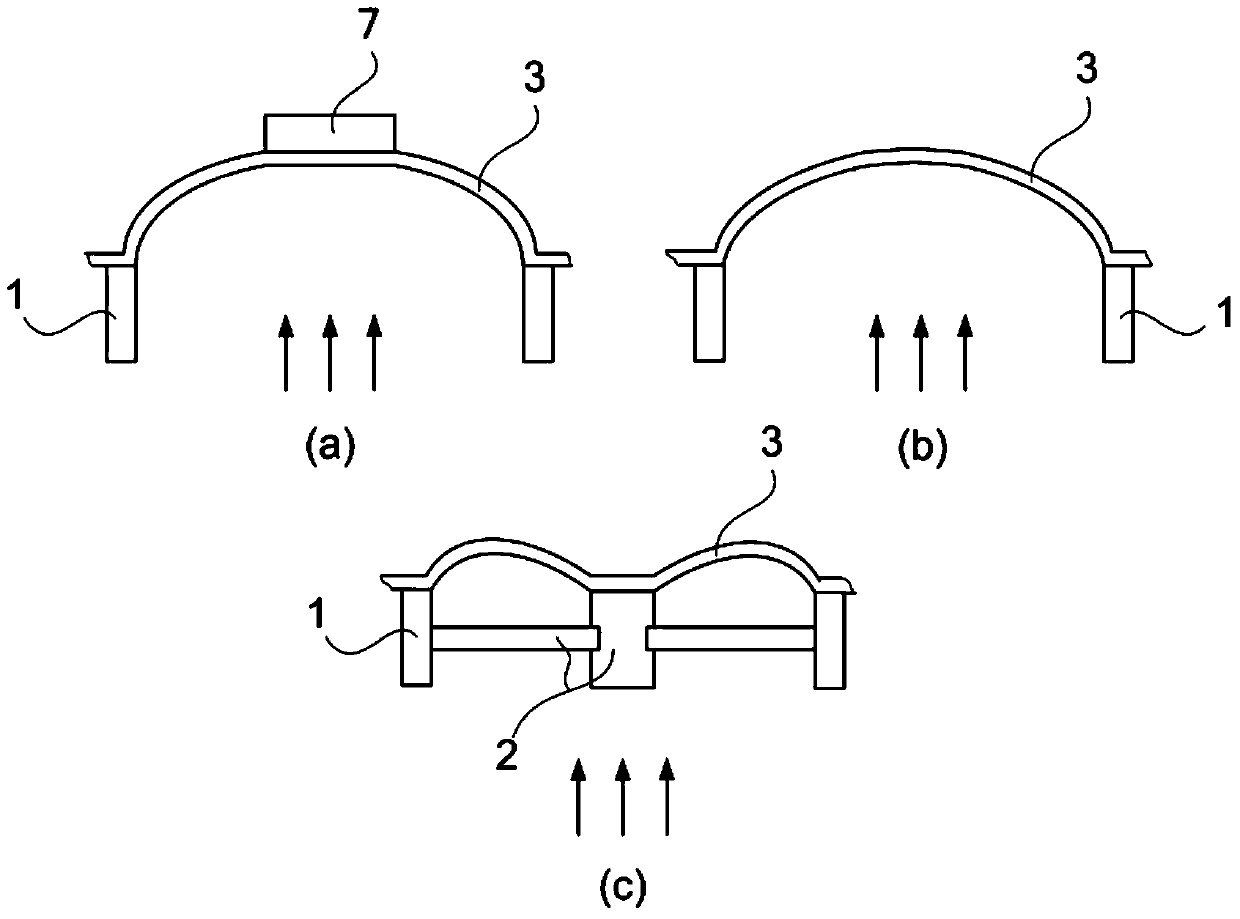

[0094] Attached below Figure 3-6 The preparation and performance measurement of the basic structural units of acoustic metamaterials are described.

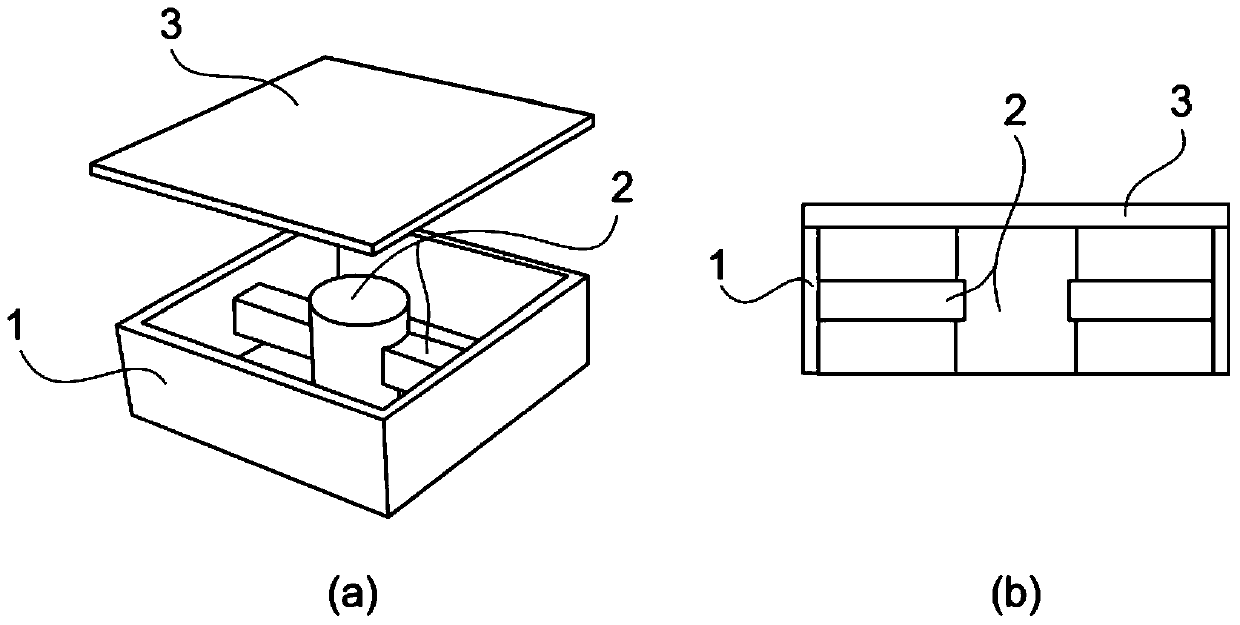

[0095] 1. Preparation of basic structural unit samples of acoustic metamaterials

[0096] Use FR-4 glass fiber to make a square boundary constraint frame 1 with an inner side length of 26mm, an outer side length of 29mm, and a height of 10mm. It is made of FR-4 glass fiber such as image 3 As shown in the frame constraining body 2, the boundary constraining frame 1 and the frame constraining body 2 are connected into the shape by integral molding. The first film 3 is selected to be a polyetherimide (Polyetherimide) film with a thickness of 0.05mm, and the first film 3 is connected and attached to the boundary constraint frame 1 and the frame constraint body 2 in a freely stretched state, The bonded contact area betwe...

Embodiment 2

[0105] Example 2 Preparation and Performance Measurement of Basic Structural Units of Acoustic Metamaterials with Two Layers of Thin Films

[0106] 1. Preparation of basic structural unit samples of acoustic metamaterials

[0107] Use FR-4 glass fiber to make a square bounding box 1 with an inner side length of 30mm, an outer side length of 33mm, and a height of 10mm. It is made of FR-4 glass fiber, such as Figure 7 As shown in the frame constraining body 2, the boundary constraining frame 1 and the frame constraining body 2 are connected into the shape by integral molding. Both the first film 3 and the second film 9 are selected to be a polyetherimide (Polyetherimide) film with a thickness of 0.05 mm, and the first film 3 is bound to the boundary constraint frame 1 and the frame constraints in a freely stretched state. The body 2 is connected and attached to the upper surface of the boundary constraining frame 1, and the contact area between the constraining body 2 in the f...

Embodiment 3

[0111] Example 3 Preparation and Performance Measurement of Acoustic Metamaterial Composite Structure

[0112] The basic structural units of the acoustic metamaterial prepared in Example 1 are arranged and distributed in the in-plane direction (xy plane) to form the acoustic metamaterial plate 5 . Choose 1 inch thick flow resistance rate of 21000 / Nsm -4 The glass fiber cotton board 10 and the 1mm thick 6063 aluminum alloy board 11 are made into traditional acoustic material boards. The acoustic metamaterial plate is directly contacted with the traditional acoustic material plate and slightly extruded, such as Figure 9 Acoustic composite structure shown. Measure the sound insulation of the standing wave tube, the measured curve is as follows Figure 10. Wherein, the dot solid line corresponds to the sound insulation of the sample in Example 3 of the present invention; the cross solid line corresponds to the sound insulation of the 1 mm uniform 6063 aluminum alloy plate 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com