Preparation method of flower cluster-shaped zinc oxide hybrid material based on cellulose nanosphere crystal as template

A hybrid material, nanosphere technology, applied in zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as insufficient controllability, high temperature requirements, and lack of performance , to achieve the effect of strong catalytic ability and antibacterial property, simple and easy preparation process, and overcoming poor adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Stir 31.25 parts by weight of the suspension of cellulose nanospherulites thoroughly, ultrasonically treat for 10 minutes, and mix with a solution of 6.25 parts by weight of zinc nitrate and 62.5 parts by weight of deionized water, and stir thoroughly; mix the mixed solution with concentrated ammonia (6mol / L) Adjust the pH value to 11.0, then fully stir for 15min; transfer to an oil bath, stir and heat to 100°C, condense and reflux, and react at constant temperature for 2h.

[0022] The above reaction solution was cooled to room temperature, filtered and washed with water for 3 times, and transferred to an oven at 80°C for 20 hours. The product obtained was figure 1 It can be seen that the morphology is a flower cluster-like zinc oxide hybrid particle, and the diameter of the nanorods forming the flower cluster is about 50-100 nm.

Embodiment 2

[0024] Stir 31.25 parts by weight of the suspension of cellulose nanospherulites fully, ultrasonically treat for 11 minutes, and mix with 6.25 parts by weight of zinc nitrate and 62.5 parts by weight of deionized water, and stir thoroughly; mix the mixed solution with concentrated ammonia (6mol / L) Adjust the pH value to 11.2, then fully stir for 18min; transfer to an oil bath, stir and heat to 115°C, condense and reflux, and react at constant temperature for 2.5h.

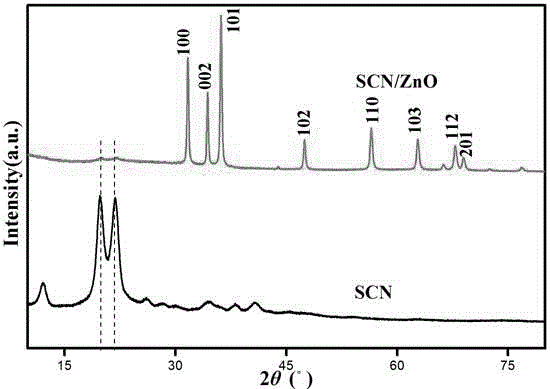

[0025] The above reaction solution was cooled to room temperature, filtered and washed with water for 3 times, and transferred to an oven at 100°C for 5 hours. According to figure 2 It can be seen that the XRD pattern shows new absorption peaks at 31.7°, 34.3°, 36.2°, 47.5°, 56.4°, 62.8°, 67.7°, and 69.1°, which correspond to the hexagonal wurtzite of zinc oxide The structure is the plane at (100), (002), (101), (102), (110), (103), (112).

Embodiment 3

[0027] Stir 31.25 parts by weight of the suspension of cellulose nanospherulites fully, ultrasonically treat for 15 minutes, and mix with 6.25 parts by weight of zinc nitrate and 62.5 parts by weight of deionized water, and stir thoroughly; mix the mixed solution with concentrated ammonia (6mol / L) The pH value was adjusted to 10.89, and then fully stirred for 28min; transferred to an oil bath, stirred and heated to 128°C, condensed and refluxed, and reacted at constant temperature for 1.5h.

[0028] The above reaction solution was cooled to room temperature, filtered and washed with water for 3 times, and transferred to an oven at 90°C for 15h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com