Method for manufacturing moth-proof and low-formaldehyde wardrobe plate

A production method and anti-insect technology, applied in the jointing of wooden veneers, chemical instruments and methods, manufacturing tools, etc., can solve the problems of easy deformation, easy fatigue, vomiting, short service life, etc., and achieve improved water resistance and adhesion The effect of improving the junction strength, reducing the amount of formaldehyde emission, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

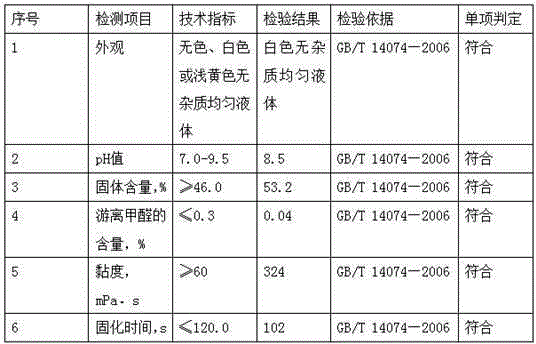

Examples

Embodiment l

[0032] A manufacturing method of insect-proof low-aldehyde wardrobe board includes the following steps:

[0033] (1) Rotating wood board: Rotary cutting the eucalyptus wood board with a rotary cutting machine to obtain the veneer, and pick out the unqualified boards with wormholes, decay, and excessive defects;

[0034] (2) Drying: Dry the veneer with a dryer to reduce the moisture content of the board to below 12%;

[0035] (3) Repair: repair the defects or blemishes on the veneer including natural cracks, cracks, knots, sandwiches and knots;

[0036] (4) Adhesive application: apply adhesive to the repaired veneer with an applicator, and form the blanks according to the direction of the upper and lower adjacent veneer textures perpendicular to each other. The amount of glue applied on one side is 225g / m 2 ;

[0037] (5) Pre-compression: Pre-compress the assembled slab at a unit pressure of 0.9~1.3MPa for 50min;

[0038] (6) Hot pressing: use a hot press for hot pressing, the hot pressin...

Embodiment 2

[0048] A manufacturing method of insect-proof low-aldehyde wardrobe board includes the following steps:

[0049] (1) Rotating wood board: Rotary cutting the eucalyptus wood board with a rotary cutting machine to obtain the veneer, and pick out the unqualified boards with wormholes, decay, and excessive defects;

[0050] (2) Drying: Dry the veneer with a dryer to reduce the moisture content of the board to below 12%;

[0051] (3) Repair: repair the defects or blemishes on the veneer including natural cracks, cracks, knots, sandwiches and knots;

[0052] (4) Adhesive application: apply adhesive to the repaired veneer with an applicator, and form the blank according to the direction of the upper and lower adjacent veneer textures perpendicular to each other. The amount of glue applied on one side is 230g / m 2 ;

[0053] (5) Pre-compression: Pre-compress the assembled slab at a unit pressure of 0.9~1.3MPa for 65min;

[0054] (6) Hot pressing: use a hot press for hot pressing, the hot pressing...

Embodiment 3

[0064] A method for manufacturing an insect-proof low-aldehyde wardrobe board, which is characterized in that it comprises the following steps:

[0065] (1) Rotating wood board: Rotary cutting the eucalyptus wood board with a rotary cutting machine to obtain the veneer, and pick out the unqualified boards with wormholes, decay, and excessive defects;

[0066] (2) Drying: Dry the veneer with a dryer to reduce the moisture content of the board to below 12%;

[0067] (3) Repair: repair the defects or blemishes on the veneer including natural cracks, cracks, knots, sandwiches and knots;

[0068] (4) Adhesive application: apply adhesive to the repaired veneer with an applicator, and form the blank according to the direction of the upper and lower adjacent veneer textures. The amount of glue applied on one side is 235g / m 2 ;

[0069] (5) Pre-compression: Pre-compress the assembled slab under the unit pressure of 0.9~1.3MPa for 75min;

[0070] (6) Hot pressing: use a hot press for hot pressing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com