Steam cabinet water tank

A water tank and steaming cabinet technology, applied in the field of kitchen utensils, can solve the problems of heat loss, water tank damage, heat loss, etc., and achieve the effects of improving thermal efficiency, improving thermal efficiency, and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

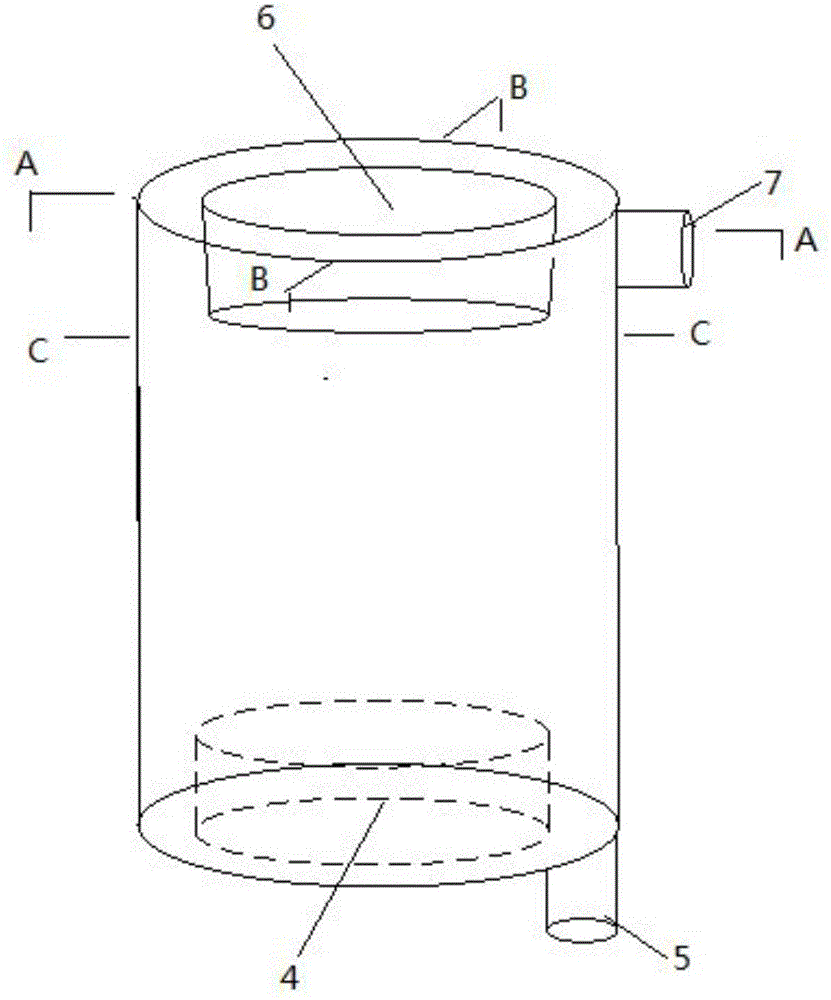

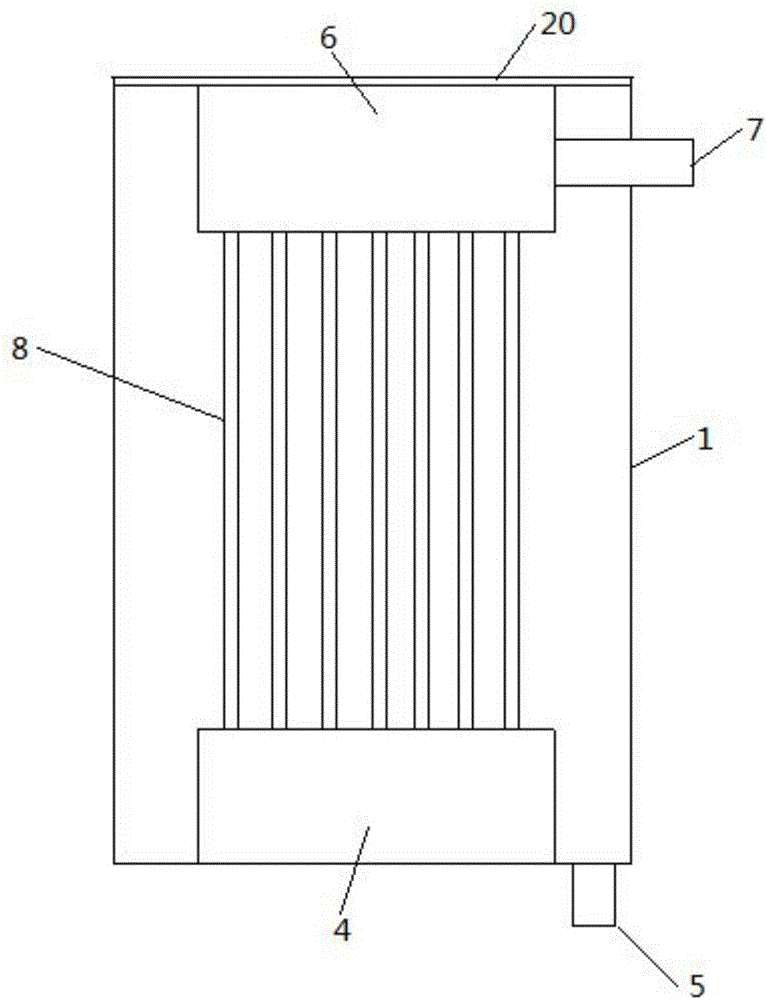

[0024] A water tank for a steamer, as shown in the figure, includes a water tank body 1, a water inlet 2 and an air outlet arranged on the side wall of the water tank body 1, the central area of the lower end surface of the water tank body 1 protrudes upwards and passes through the flange of the peripheral area The hole 18 mounting flange is sealed and connected with the burner to form a combustion chamber 4, and a drain port 5 is arranged on the lower end surface outside the combustion chamber. The plate 20 forms a flue gas buffer chamber 6, and one side of the flue gas buffer chamber 6 is provided with a smoke exhaust pipe 7 passing through the water tank body, and the smoke exhaust pipe 7 is provided with a CO sensor.

[0025] The inside of the water tank body 1 is provided with twelve heat exchange fins 8, the heat exchange fins include a bottom plate 8a and a heat exchange tube 8b arranged on the bottom plate 8a, the nozzle of the heat exchange tube 8b extends from the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com