Industrial water treatment bactericide

A technology for industrial water treatment and fungicides, applied in the directions of fungicides, biocides, biocides, etc., can solve the problems of increased drug dosage, refractory degradation, corrosion or erosion, etc., and achieves low use cost, high biocide efficiency, and compatibility good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

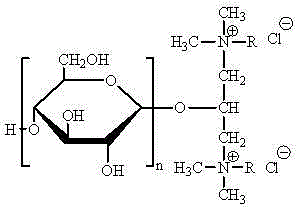

Image

Examples

Embodiment 1

[0023] The industrial water treatment bactericide of the present embodiment is composed of four components of glycosyl gemini quaternary ammonium salt, alkyl glycoside, isothiazolinone and sodium dichloroisocyanurate, and the specific ratio is as follows:

[0024] Sugar Gemini Quaternary Ammonium Salt 25kg

[0026] Isothiazolinone 4kg

[0027] Sodium dichloroisocyanurate 10kg

[0028] In this embodiment, the glycosyl gemini quaternary ammonium salt is a glycosyl gemini quaternary ammonium salt whose carbon chain length is respectively dodecyl; the alkyl chain of the alkyl glycoside is decyl.

[0029] The steps of the preparation method of the industrial water treatment bactericide of the present embodiment are as follows: the glycosyl gemini quaternary ammonium salt, the alkyl glycoside, the isothiazolinone and the sodium dichloroisocyanurate are weighed according to the formula, and then added into the stirring tank, and mechanically Mix evenly...

Embodiment 2

[0031] The industrial water treatment bactericide of the present embodiment is composed of four components of glycosyl gemini quaternary ammonium salt, alkyl glycoside, isothiazolinone and sodium dichloroisocyanurate, and the specific ratio is as follows:

[0032] Sugar Gemini Quaternary Ammonium Salt 18kg

[0034] Isothiazolinone 9kg

[0035] Sodium dichloroisocyanurate 5kg

[0036] In this embodiment, the glycosyl gemini quaternary ammonium salt is a glycosyl gemini quaternary ammonium salt whose carbon chain length is respectively decyl; the alkyl chain of the alkyl glycoside is tetradecyl.

Embodiment 3

[0038] The industrial water treatment bactericide of the present embodiment is composed of four components of glycosyl gemini quaternary ammonium salt, alkyl glycoside, isothiazolinone and sodium dichloroisocyanurate, and the specific ratio is as follows:

[0039] Sugar Gemini Quaternary Ammonium Salt 20kg

[0041] Isothiazolinone 8kg

[0042] Sodium dichloroisocyanurate 7kg

[0043] In this embodiment, the glycosyl gemini quaternary ammonium salt is a glycosyl gemini quaternary ammonium salt whose carbon chain length is tetradecyl respectively; the alkyl chain of the alkyl glycoside is octyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com