Pyrolysis amorphous carbon material and preparation method and application thereof

An amorphous carbon, amorphous technology, applied in the field of materials, can solve the problems of large mass loss, poor cycle performance, high cost of hard carbon, and achieve high working voltage and energy density, good safety performance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 of the present invention provides a pyrolytic amorphous carbon material, which is granular, and the average particle size of the particles is 1-100 μm; d 002 Value between 0.35-0.44nm, L c Value between 0.5-4nm, L a The value is between 3-5nm;

[0061] The raw materials for its preparation include a hard carbon precursor and a soft carbon precursor; the mass ratio of the hard carbon precursor to the soft carbon precursor is 1: (0.1-10).

[0062] The hard carbon precursor can be selected from one or any mixture of glucose, sucrose, lignin, cellulose, starch, phenolic resin, polyacrylonitrile, epoxy resin; the soft carbon precursor can be selected from kerosene pitch, petroleum pitch , Mesophase pitch or any mixture of several.

[0063] The pyrolytic amorphous carbon material provided in this embodiment can be used as a negative electrode material for a sodium-ion secondary battery or a lithium-ion secondary battery. Mixing hard carbon precursors and soft ca...

Embodiment 2

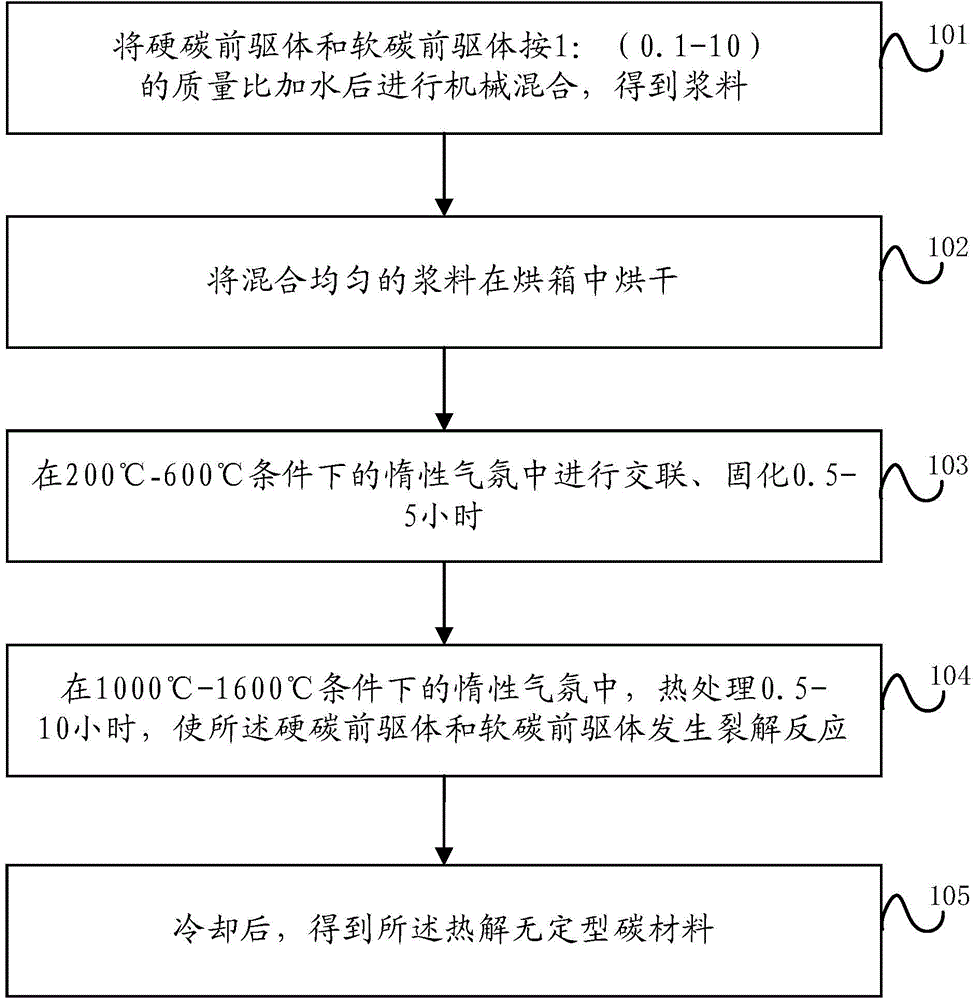

[0065] The present embodiment provides a kind of preparation method of pyrolysis amorphous carbon material, and its steps are as follows figure 1 shown, including:

[0066] Step 101, mechanically mixing the hard carbon precursor and the soft carbon precursor with a solvent at a mass ratio of 1: (0.1-10) to obtain a slurry;

[0067] Specifically, the solvent can be selected from one or any mixture of water, ethanol, isopropanol, acetone, dimethylformamide; the hard carbon precursor can be selected from glucose, sucrose, lignin, cellulose, starch, One or any mixture of phenolic resin, polyacrylonitrile, and epoxy resin; the soft carbon precursor can be selected from one or any mixture of coal tar pitch, petroleum pitch, and mesophase pitch.

[0068] Mechanical mixing includes ball milling, stirring or ultrasonic dispersion, and any combination of the above methods.

[0069] The time of mechanical mixing can be set according to the selected precursor and the mixing method used....

Embodiment 3

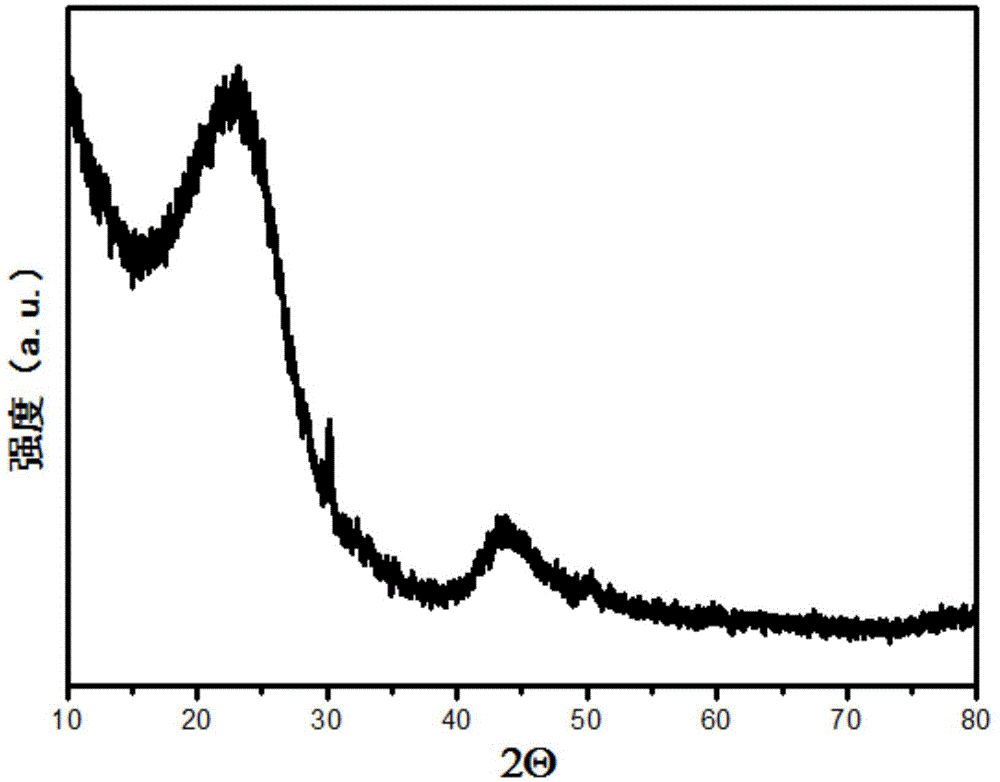

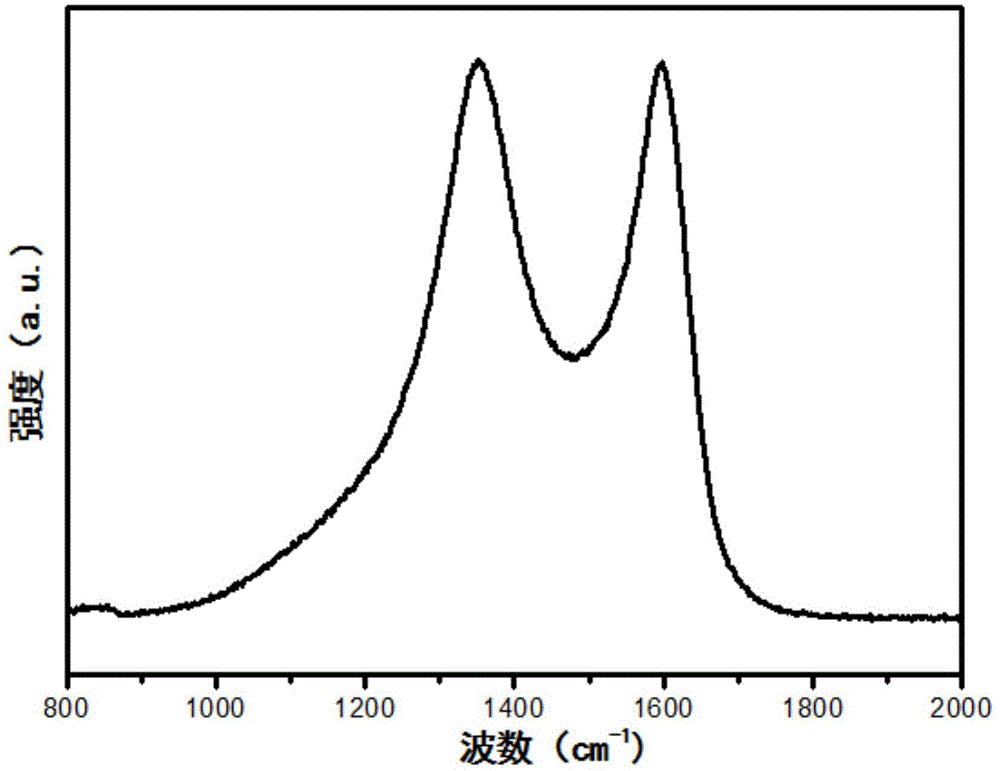

[0083] Weigh 2g of lignin, 2g of petroleum pitch and appropriate amount of water into the ball mill, mix and ball mill for 5 hours at room temperature, dry the slurry obtained after ball milling, put it into a magnetic boat and put it into a tube furnace; As a protective gas, raise it to 500°C at a rate of 1°C / min and hold it for 2 hours; then raise it to 1300°C at a rate of 3°C / min and hold it for 2 hours; then cool it down to room temperature naturally, take out the material, and crush it to get The final amorphous carbon material. After measurement, the carbon production rate is 60%. Its X-ray diffraction (XRD) pattern see figure 2 , the d of the amorphous carbon material can be obtained from the XRD pattern 002 = 0.398nm, L c = 0.834nm. Its Raman spectrum see image 3 , the amorphous carbon material L can be obtained from the Raman spectrum a = 4.382nm. Figure 4 The scanning electron microscope (SEM) picture of the amorphous carbon material prepared for this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

| Reversible specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com