Test device and test method for observing hole machining outlet

An experimental device and hole machining technology, which is applied in the field of hole making, can solve the problems of real-time temperature measurement, inability to observe the cutting process at the exit of hole making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

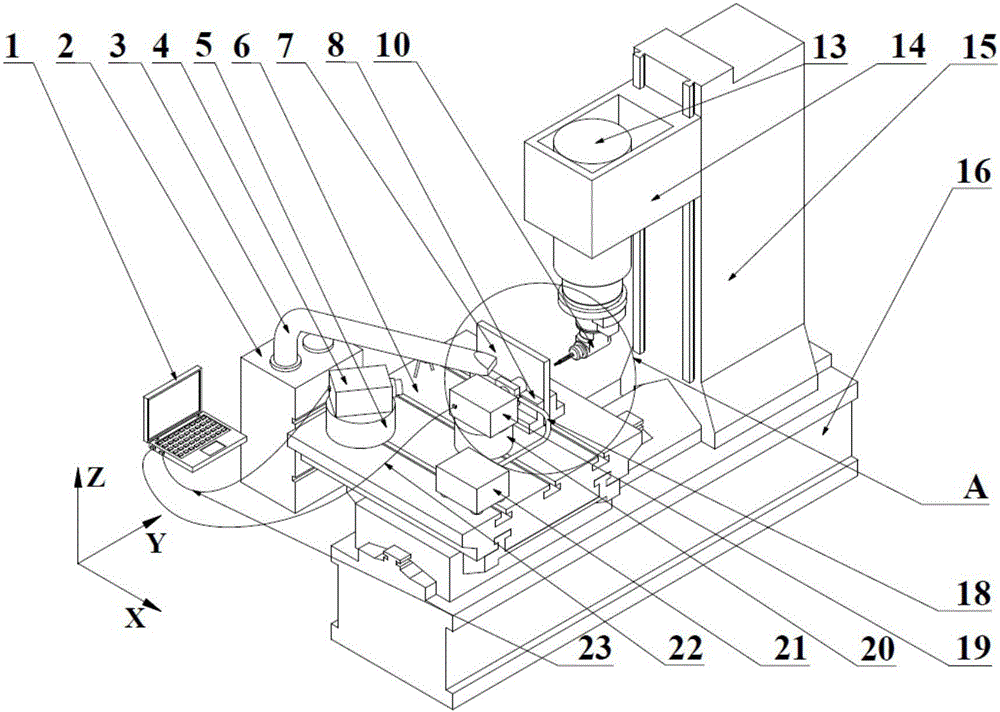

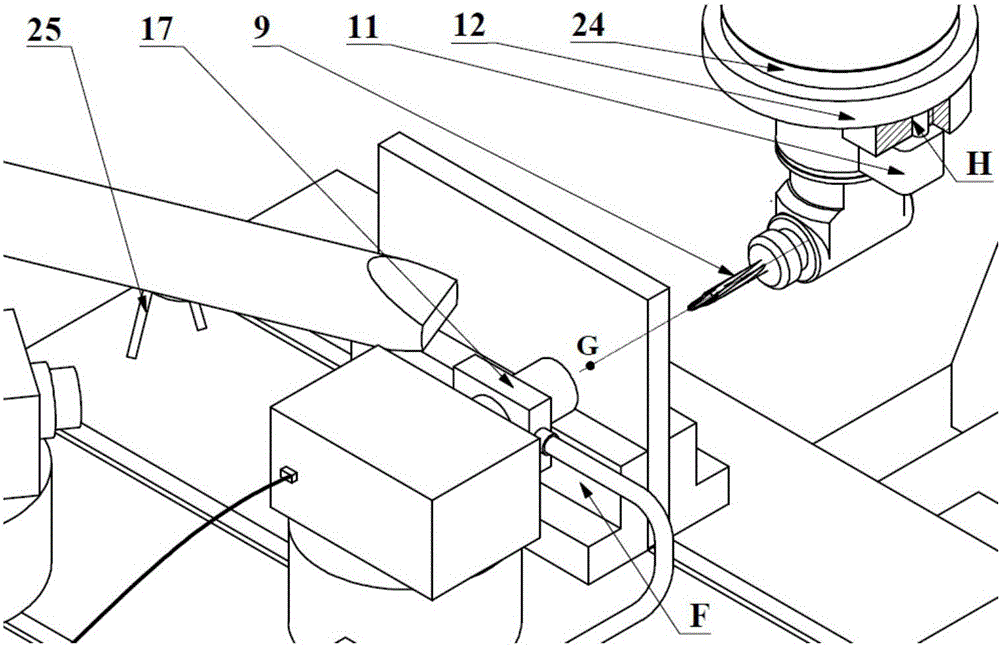

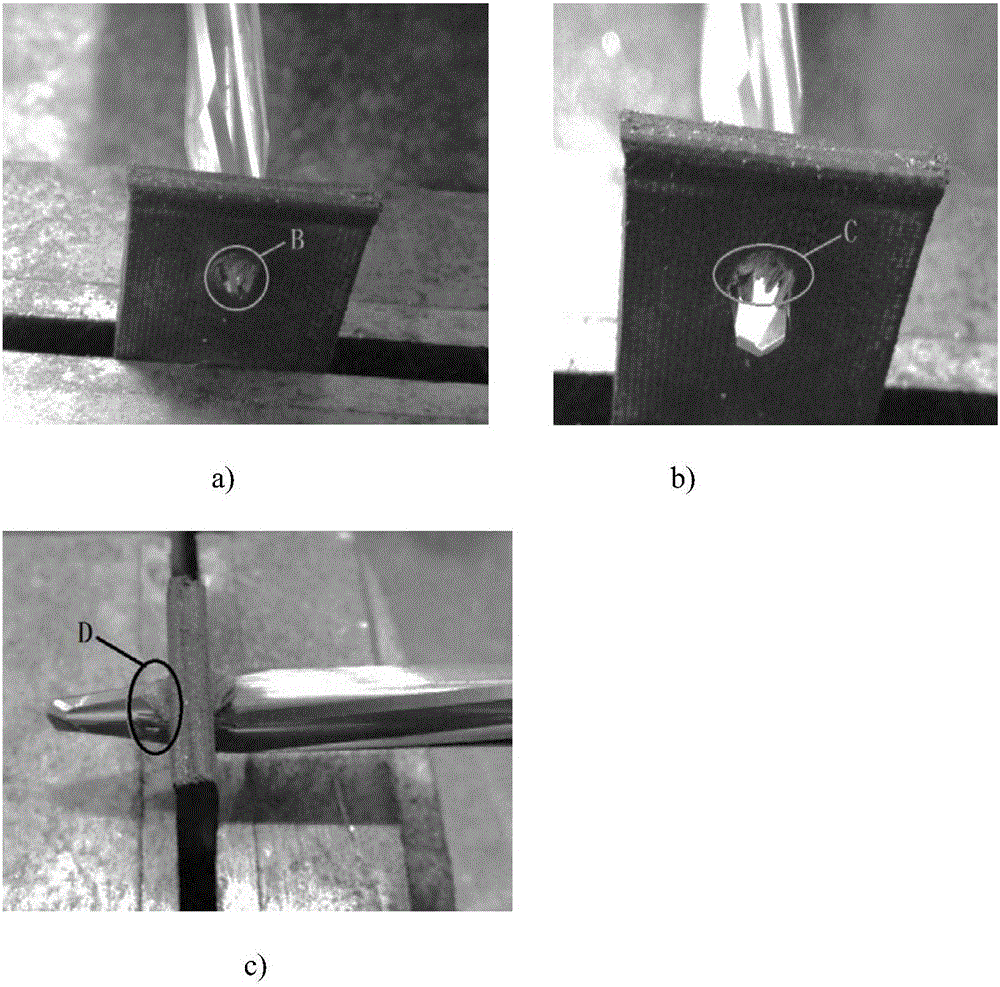

[0020] The specific implementation process of a method and device for hole-making and processing exit observation will be described in detail below in conjunction with the accompanying drawings and technical solutions. in the attached figure 1 Among them, the bed 16 in the experimental device is the basic support part in the whole drilling process; the bed 16 is equipped with a linear displacement workbench 6 and a bed column 15; On the spindle box 14, the angle head 10 is installed in the Morse taper hole of the main shaft part 13 through the Morse taper hole, the adapter ring 12 and the main shaft part 13 are clamped by bolts, and the limit block 11 on the angle head 10 is inserted into the adapter The positioning is carried out in the limit hole H of the ring 12, and the machining axial direction of the angle head 10 is fixed so that it is parallel to the drilling feed direction Y of the machine tool; the fixture 8 is fixed on the linear displacement table 6, and the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com