A solvent-free electrospinning device based on UV curing

An electrospinning, solvent-free technology, applied in the field of solvent-free electrospinning devices, can solve the problems of troublesome preparation of precursor liquid, incomplete curing, short fibers, etc., and achieve complete curing, good uniformity, and good fiber continuity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

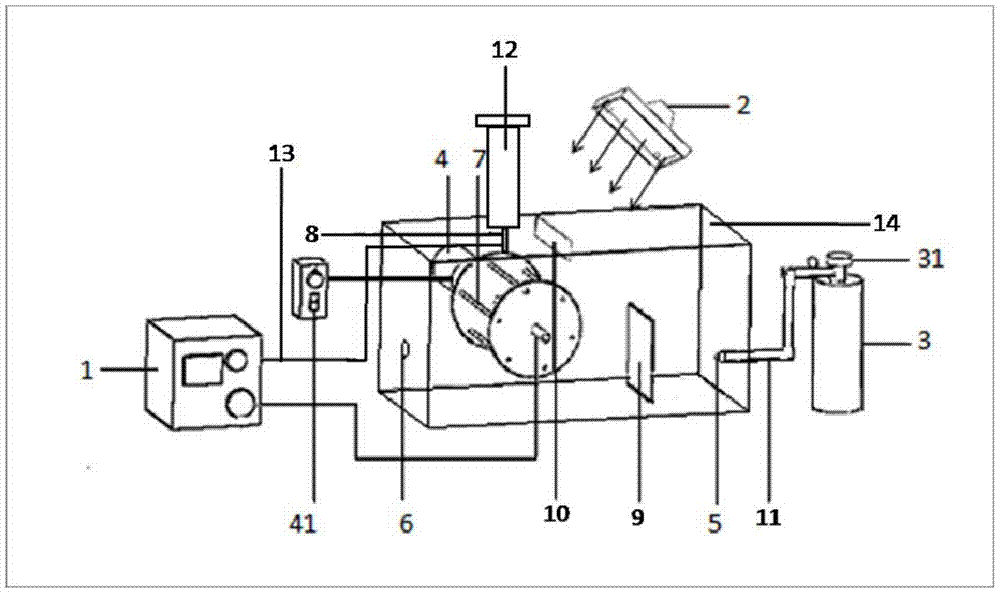

[0035] Such as figure 1 As shown, a solvent-free electrospinning device based on UV curing includes a high-voltage power supply 1, a liquid storage mechanism 12, a spinning nozzle 8, an oxygen barrier mechanism, an ultraviolet light source 2 and a collector, and the positive pole of the high-voltage power supply 1 is connected to the spinning The silk nozzle 8 and the spinning nozzle 8 are connected to the liquid storage mechanism 12 for storing the spinning precursor solution. The liquid storage mechanism 12 is a plastic syringe needle tube, the collector is connected to the negative pole of the high-voltage power supply 1, and the oxygen barrier mechanism includes an internal anaerobic Or a sealed box 14 with less oxygen, the spinning nozzle 8 and the collecting pole are located in the sealed box 14, and the ultraviolet light source 2 is located outside the sealed box 14, and the ultraviolet light emitted by it can be injected into the sealed box 14, and the ultraviolet light...

Embodiment 2

[0039] The solvent-free electrospinning device based on UV curing of embodiment 2 is similar to the device of embodiment 1, the difference is that the sealed box of the oxygen barrier mechanism of the device of embodiment 2 is a glass vacuum desiccator, and the glass vacuum desiccator is connected to Vacuum pump, the ultraviolet light source is located in a sealed box, the ultraviolet light source can irradiate between the spinning nozzle and the collecting pole, the collecting pole is grounded on an aluminum plate, and the liquid storage mechanism in embodiment 2 is an aluminum tank connected to the spinning nozzle .

Embodiment 4

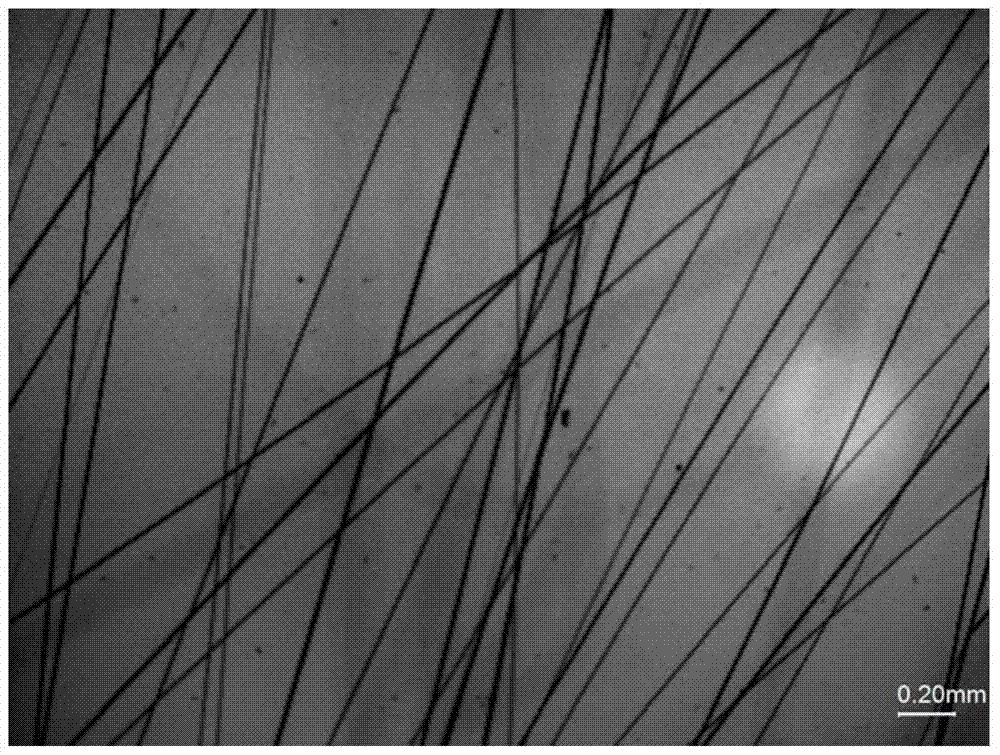

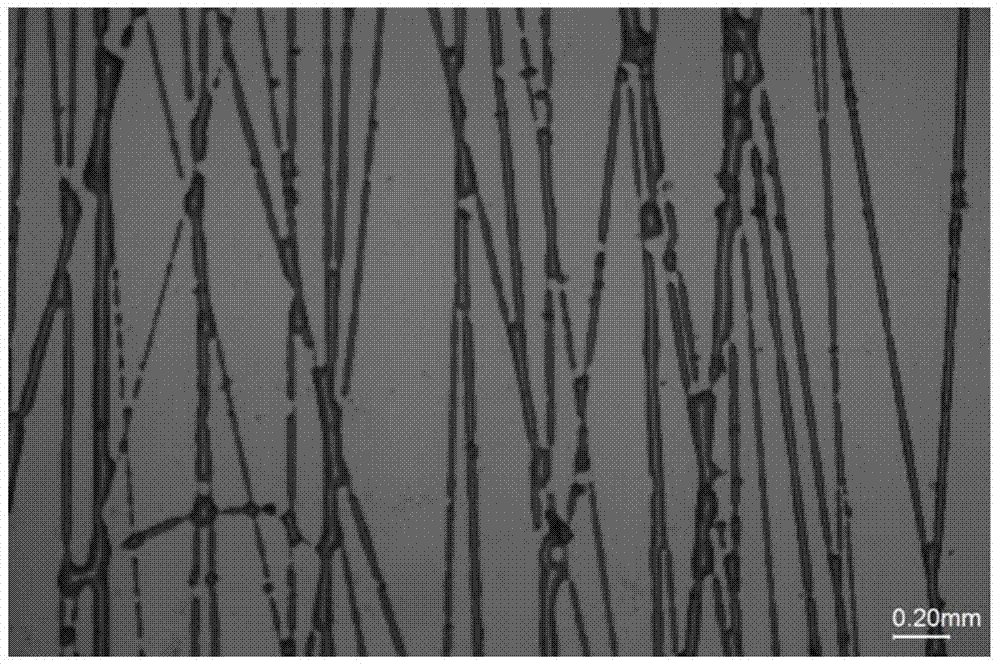

[0052] The device of application example 1 is used to prepare ordered polyurethane acrylate micro-nano fibers, comprising the following steps:

[0053] (1) Add 0.5 gram of solid-state photoinitiator (184,1-hydroxy-cyclohexyl-phenyl ketone, Aldrich) in the Erlenmeyer flask, then add 9 grams of polyurethane acrylate (DR-U301, Changxing Chemical Industry Co., Ltd. (Taiwan)), carry out light-shielding stirring with a magnetic stirrer, adopt 50 degree water bath to heat, stir for 1 hour, make the solid-state photoinitiator and polyurethane acrylate mix and dissolve evenly.

[0054] (2) Stand at room temperature for 1 day to prepolymerize the urethane acrylate to a certain extent.

[0055] (3) Inject the prepared precursor solution into the liquid storage mechanism of the device in Example 1. The spinning nozzle is an aluminum nozzle with an inner diameter of 2 mm at the injection end, and a carbon dioxide gas cylinder is used as the gas source, and carbon dioxide is introduced into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com