Low energy uv curing polyurethane acrylate prepolymer and its preparation method and uv curing coating

A polyurethane acrylate and acrylate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of strong odor and insufficient storage stability, and achieve the effects of good toughness, fast UV curing speed and stable storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] Further, the present invention also provides the preparation method of described low-energy UV curing urethane acrylate prepolymer, comprising the following steps:

[0049] A) Vacuum dehydrate the diol polymer, lower the temperature to 40-60°C, add an organotin catalyst and stir well, add diisocyanate dropwise to it, and keep warm at 40-60°C until the NCO value is the initial (50± 1)%.

[0050] B) Add carboxyl-containing chain extender and stir well, heat up to 60-80°C to react until the NCO value is (25±1)% of the initial value, then cool down to 50-60°C.

[0051] C) Add acrylate end-capping agent, mercaptan end-capping agent and polymerization inhibitor, keep warm at 60-80°C, and stop the reaction until the NCO value is below 0.1%, to obtain a low-energy UV-curable polyurethane acrylate prepolymer.

[0052] Wherein, in step A, the process of vacuum dehydration may be vacuum dehydration at 105° C. for 2 hours. Preferably, after the diisocyanate is added dropwise, the...

Embodiment 1

[0057] In parts by weight, vacuumize 100 parts of polytetrahydrofuran glycol PTMG (BASF PolyTHF250, relative molecular weight 250) at 105°C for 2 hours to remove the moisture, then cool down to 40°C, add 0.1 part of dibutyltin dilaurate and stir well , 135.5 parts of 1,6-hexamethylene diisocyanate was added dropwise thereto, and after the temperature became constant, the reaction was maintained at 40°C until the NCO value was (50±1)% of the initial value.

[0058] Add 30 parts of dimethylolbutyric acid and stir evenly, raise the temperature to 60°C to react until the NCO value is (25±1)% of the initial value, and then cool down to 50°C.

[0059] Add 16 parts of hydroxyethyl acrylate, 21 parts of 2-mercaptoethanol and 0.3 parts of hydroquinone, keep the temperature constant at 60°C for reaction, stop the reaction until the NCO value is below 0.1%, and obtain low-energy UV-curable polyurethane acrylate prepolymer.

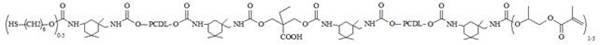

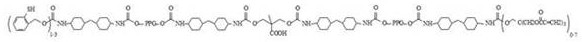

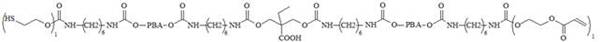

[0060] In the present embodiment, according to above raw mater...

Embodiment 2

[0063] In parts by weight, vacuumize 100 parts of polycarbonate diol PCDL (Ube UBE PH100, relative molecular weight 1000) at 105°C for 2 hours to remove the moisture, then cool down to 60°C, and add 0.1 part of dibutyltin diacetate Stir well, add 44.5 parts of isophorone diisocyanate dropwise to it, wait for the temperature to be constant and keep it warm at 60°C to react until the NCO value is (50±1)% of the initial value.

[0064] Add 7.5 parts of dimethylolbutyric acid and stir well, raise the temperature to 80°C for reaction until the NCO value is (25±1)% of the initial value, and then cool down to 60°C.

[0065] Add 10.7 parts of hydroxypropyl methacrylate, 3.6 parts of 6-mercapto-1-hexanol and 0.15 parts of p-hydroxyanisole, keep the temperature constant at 80°C for reaction, and stop the reaction until the NCO value is below 0.1%. Energy UV curable urethane acrylate prepolymer.

[0066] In the present embodiment, according to above raw material, the theoretical structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com