UV curing offset printing ink and use

An offset printing ink and packaging printing technology, applied in the field of printing ink, can solve the problems of dependence on imports and high cost, and achieve the effects of improving the environment, high production efficiency, excellent solvent resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

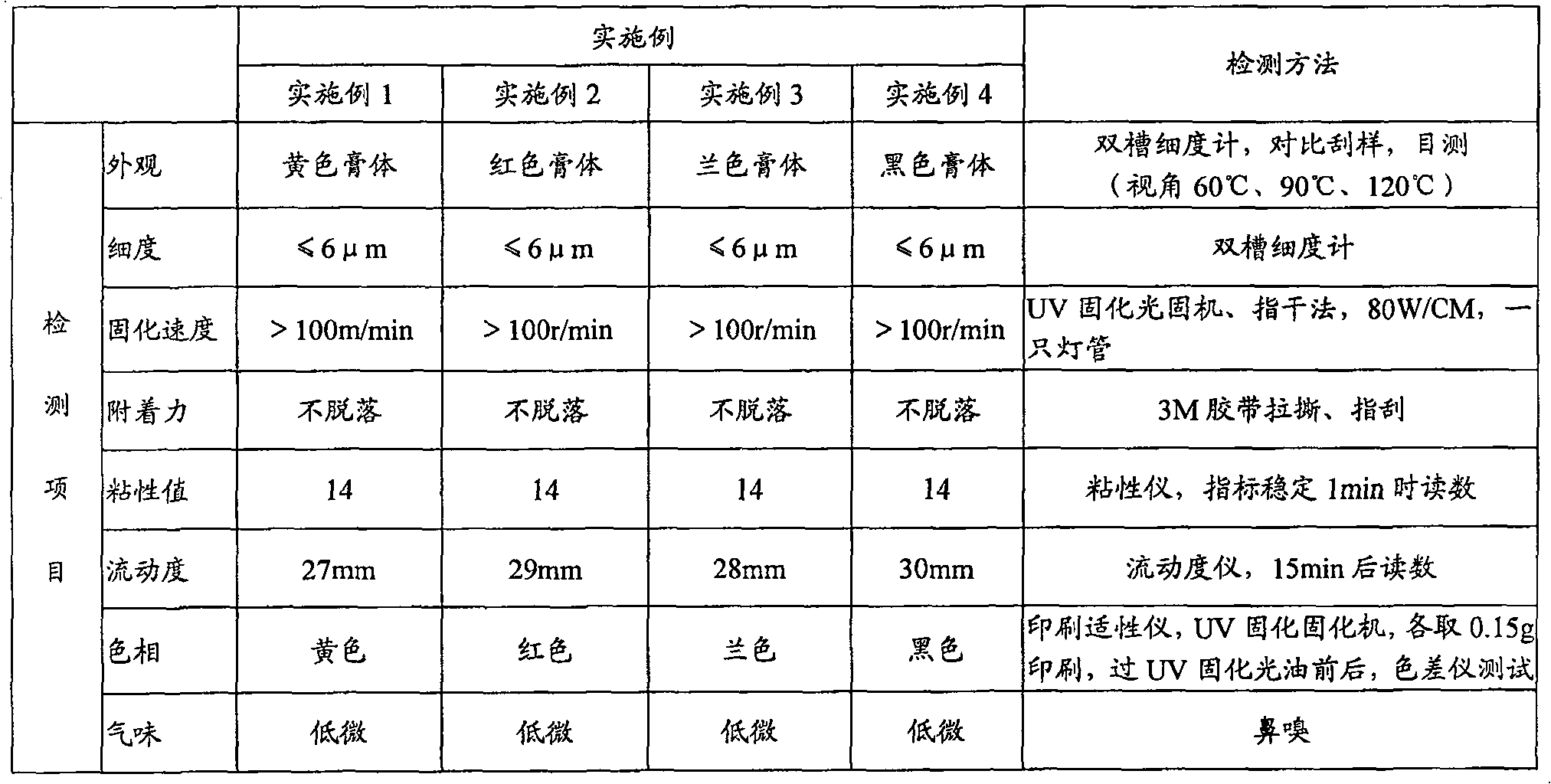

Examples

Embodiment 1

[0052] Get 42 parts (weight) of polyester acrylate, under the stirring condition of mixer speed > 600r / min, add 5 parts (weight) of epoxy acrylate, 20 parts (weight) of high-viscosity monofunctional polyurethane acrylate, 3 parts (weight) of acrylic monomer part (weight), 10 parts (weight) of photoinitiator, disperse at high speed, stir, until photoinitiator is all dissolved. Under the condition that the rotational speed of the mixer is less than 300r / min, 4 parts (by weight) of fillers and 16 parts (by weight) of yellow organic pigments are added. After the materials are mixed evenly, under the condition of the speed of the mixer > 600r / min, disperse at a high speed, fully wet the powder, and then use a three-roller to grind to a fineness of ≤ 6um to obtain the finished product.

Embodiment 2

[0054] Get 42 parts (weight) of polyester acrylate, under the stirring condition of mixer speed > 600r / min, add 5 parts (weight) of epoxy acrylate, 20 parts (weight) of high-viscosity monofunctional polyurethane acrylate, 3 parts (weight) of acrylic monomer part (weight), 10 parts (weight) of photoinitiator, disperse at high speed, stir, until photoinitiator is all dissolved. Under the speed of the mixer 600r / min, disperse at a high speed to fully wet the powder. Then use a three-roller to grind to a fineness of ≤6um to obtain the finished product.

Embodiment 3

[0056] Get 42 parts (weight) of polyester acrylate, under the stirring condition of mixer speed > 600r / min, add 5 parts (weight) of epoxy acrylate, 20 parts (weight) of high-viscosity monofunctional polyurethane acrylate, 3 parts (weight) of acrylic monomer part (weight), 10 parts (weight) of photoinitiator, disperse at high speed, stir, until photoinitiator is all dissolved. Under the speed of the mixer 600r / min, disperse at a high speed to fully wet the powder. Then use a three-roller to grind to a fineness of ≤6um to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com