UV-curing-based solvent-free electrostatic spinning apparatus

An electrospinning, solvent-free technology, applied in the field of solvent-free electrospinning devices, can solve the problems of troublesome preparation of precursor liquid, incomplete curing, irregularity, etc., and achieve the effects of complete curing, good uniformity and regular morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

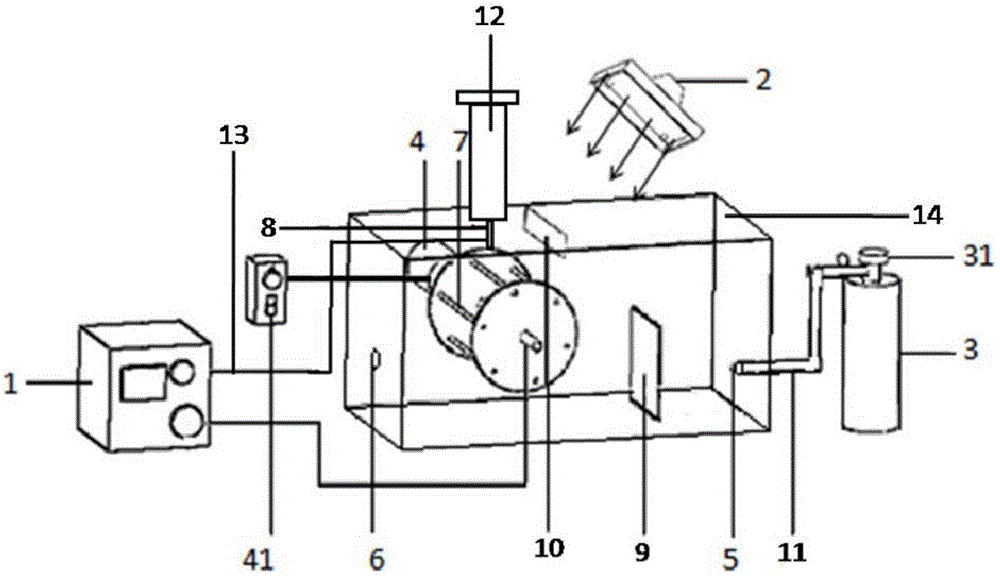

[0035] Such as figure 1 As shown, a UV curing-based solvent-free electrostatic spinning device includes a high-voltage power supply 1, a liquid storage mechanism 12, a spinning nozzle 8, an oxygen barrier, an ultraviolet light source 2, and a collector. The spinning nozzle 8 is connected to the liquid storage mechanism 12 for storing the spinning precursor liquid. The liquid storage mechanism 12 is a plastic syringe needle, the collector is connected to the negative electrode of the high-voltage power supply 1, and the oxygen barrier includes an internal oxygen-free mechanism. Or a sealed box 14 with less oxygen, the spinning nozzle 8 and the collector are located in the sealed box 14, the ultraviolet light source 2 is located outside the sealed box 14, the emitted ultraviolet light can be injected into the sealed box 14, and the ultraviolet light source 2 can illuminate Between the spinning nozzle 8 and the collector.

[0036] Specifically, the sealed box 14 of the oxygen barrie...

Embodiment 2

[0039] The UV curing-based solvent-free electrostatic spinning device of Example 2 is similar to the device of Example 1, except that the sealed box of the oxygen barrier mechanism of the device of Example 2 is a glass vacuum dryer, which is connected to the glass vacuum dryer. Vacuum pump, the ultraviolet light source is located in a sealed box, the ultraviolet light source can irradiate between the spinning nozzle and the collector, the collector is grounded on an aluminum plate, the liquid storage mechanism of embodiment 2 is an aluminum tank connected with the spinning nozzle .

Embodiment 4

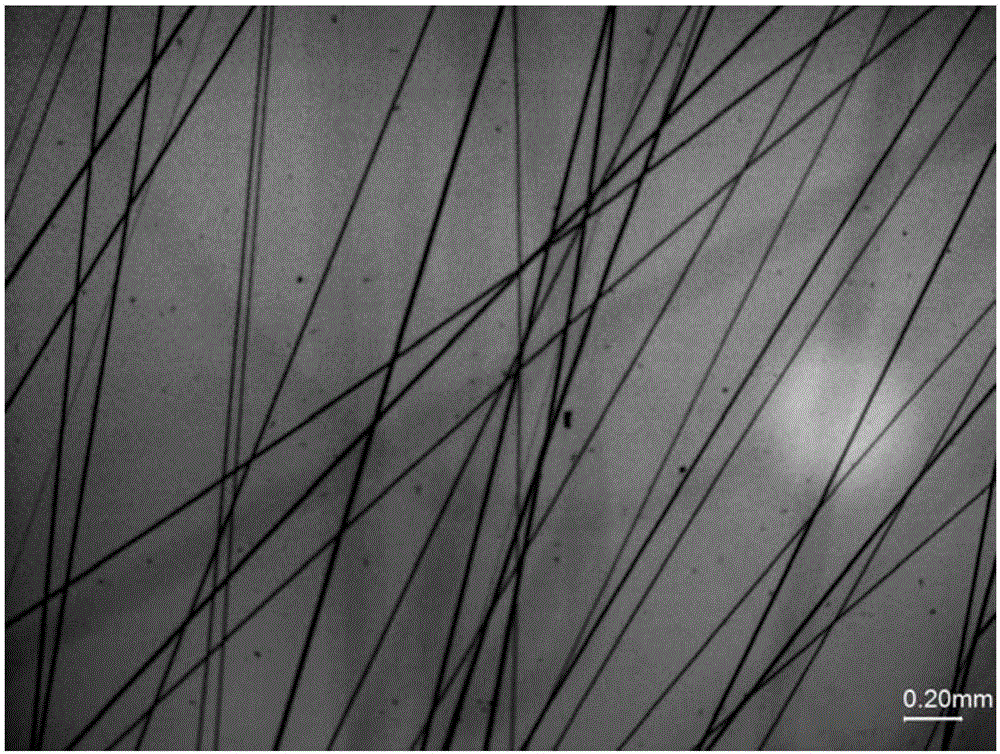

[0052] Using the device of Example 1 to prepare ordered polyurethane acrylate micro-nano fibers includes the following steps:

[0053] (1) Add 0.5 g of solid photoinitiator (184,1-hydroxy-cyclohexyl-phenyl ketone, Aldrich) into the Erlenmeyer flask, then add 9 g of polyurethane acrylate (DR-U301, Changxing Chemical Industry Co., Ltd. (Taiwan)), shading and stirring with a magnetic stirrer, heating in a 50 degree water bath, stirring for 1 hour, so that the solid photoinitiator and the polyurethane acrylate are mixed and dissolved uniformly.

[0054] (2) Let it stand for 1 day at room temperature to pre-polymerize the urethane acrylate to a certain extent.

[0055] (3) Inject the prepared precursor solution into the liquid storage mechanism of the device of Example 1. The spinning nozzle is an aluminum nozzle with an inner diameter of 2 mm at the spray end, and a carbon dioxide cylinder is used as a gas source to pass carbon dioxide into the sealed box. The gas, the gas flow rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com