A kind of method of pyrolysis gasoline hydrorefining

A technology for pyrolysis gasoline and hydrotreating, which is applied in the direction of selective hydrotreating, chemical instruments and methods, molecular sieve catalysts, etc., and can solve the problems of impurity resistance of catalysts to be improved, unstable operation of catalysts, and high prices of catalysts. The effect of easy operation condition control, high diene selectivity and long regeneration period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

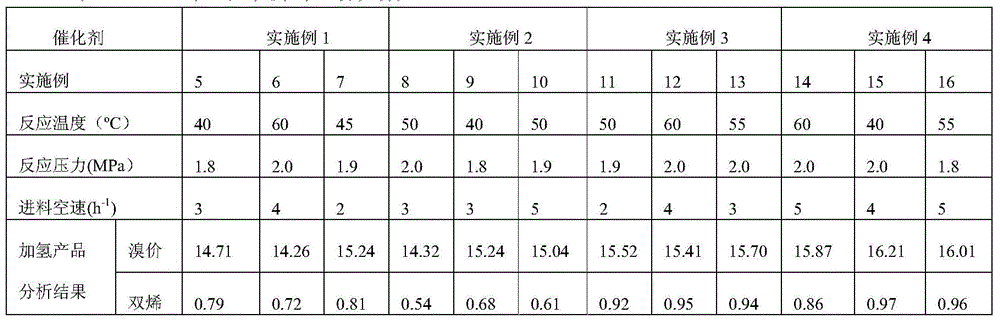

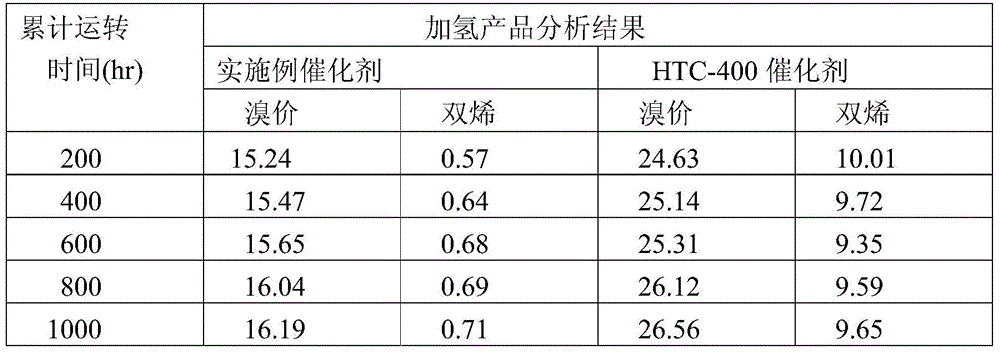

Examples

Embodiment 1

[0029] (1) Preparation of carrier

[0030] Take the specific surface area as 176m 2 / g, 100g of strip-shaped alumina with a pore volume of 0.54ml / g, impregnated with 50ml of titanium sulfate in a 0.6g / ml dilute sulfuric acid solution, stirred for 20 minutes, and dried at 110°C for 10 hours to obtain alumina- Titanium oxide. And the ratio is 4:1.

[0031] Then mix the prepared 30g of alumina-titanium oxide and 70g of ZSM-5 powder, add a certain amount of 2% dilute nitric acid solution, knead and extrude, dry at 110°C for 12 hours, and roast at 500°C After 6 hours, a composite carrier of alumina-titania and ZSM-5 powder was prepared. Alumina-titania accounts for 30% by weight, and ZSM-5 powder accounts for 70% by weight.

[0032] (2) Preparation of catalyst

[0033] Add 70.5g of nickel nitrate to 100ml of water, stir and dissolve, adjust the pH value to 5, impregnate on 100g of carrier 1, dry at 120°C for 6 hours, and then roast at 600°C for 5 hours to obtain the catalyst. ...

Embodiment 2

[0035] The preparation method of alumina-titanium oxide is the same as in Example 1, and then the prepared 40g of alumina-titanium oxide and 60g of ZSM-5 powder are mixed, and a certain amount of 2% dilute nitric acid solution is added, after kneading and extruding, the Drying at 110°C for 12 hours and calcining at 500°C for 6 hours to prepare alumina-titania and ZSM-5 powder composite carrier. Alumina-titania accounts for 40% by weight, and ZSM-5 powder accounts for 60% by weight.

[0036]Add 62.7g of nickel nitrate to 100ml of water, stir and dissolve, adjust the pH value to 5, impregnate on 100g of carrier 1, dry at 120°C for 6 hours, and then roast at 600°C for 5 hours to obtain the catalyst. The nickel oxide content is 16% by weight.

Embodiment 3

[0038] The preparation method of alumina-titanium oxide is the same as that of Example 1, and then the prepared 60g of alumina-titanium oxide and 40g of ZSM-5 powder are mixed, and a certain amount of 2% dilute nitric acid solution is added, and after kneading and extruding, the Drying at 110°C for 12 hours and calcining at 500°C for 6 hours to prepare alumina-titania and ZSM-5 powder composite carrier. Alumina-titania accounts for 60% by weight, and ZSM-5 powder accounts for 40% by weight.

[0039] Add 78.4g of nickel nitrate to 100ml of water, stir and dissolve, adjust the pH value to 5, impregnate on 100g of carrier 1, dry at 120°C for 6 hours, and then roast at 600°C for 5 hours to obtain the catalyst. The nickel oxide content is 20% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com