Hydrofining method of pyrolysis gasoline

A technology of pyrolysis gasoline and hydrofining, applied in the direction of selective hydrofining, chemical instruments and methods, molecular sieve catalysts, etc., can solve the problems of the catalyst’s anti-impurity ability to be improved, the catalyst’s unstable operation, and the catalyst’s high price. Ease of operating condition control, high diene selectivity, and long regeneration cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

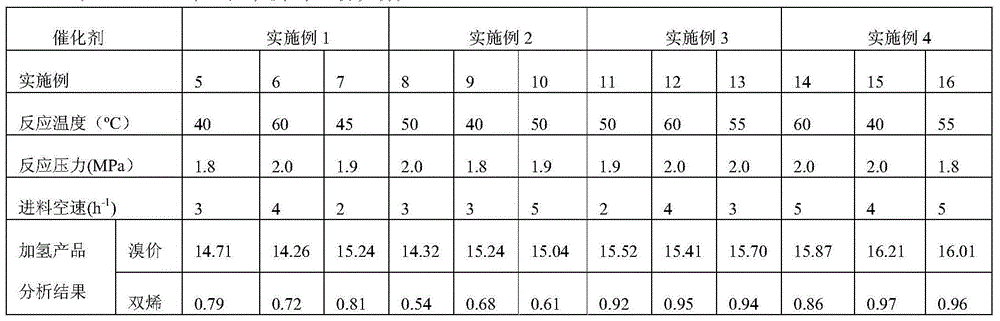

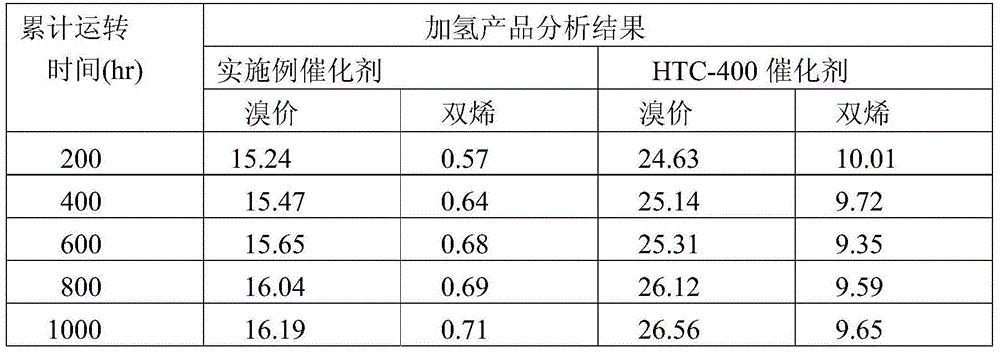

Examples

Embodiment 1

[0029] (1) Preparation of carrier

[0030] Take the specific surface area as 176m 2 / g, 100g of strip-shaped alumina with a pore volume of 0.54ml / g, impregnated with 50ml of titanium sulfate in a 0.6g / ml dilute sulfuric acid solution, stirred for 20 minutes, and dried at 110°C for 10 hours to obtain alumina- Titanium oxide. And the ratio is 4:1.

[0031] Then mix the prepared 30g of alumina-titanium oxide and 70g of ZSM-5 powder, add a certain amount of 2% dilute nitric acid solution, knead and extrude, dry at 110°C for 12 hours, and roast at 500°C After 6 hours, a composite carrier of alumina-titania and ZSM-5 powder was prepared. Alumina-titania accounts for 30% by weight, and ZSM-5 powder accounts for 70% by weight.

[0032] (2) Preparation of catalyst

[0033] Add 70.5g of nickel nitrate to 100ml of water, stir and dissolve, adjust the pH value to 5, impregnate on 100g of carrier 1, dry at 120°C for 6 hours, and then roast at 600°C for 5 hours to obtain the catalyst. ...

Embodiment 2

[0035] The preparation method of alumina-titanium oxide is the same as in Example 1, and then the prepared 40g of alumina-titanium oxide and 60g of ZSM-5 powder are mixed, and a certain amount of 2% dilute nitric acid solution is added, after kneading and extruding, the Drying at 110°C for 12 hours and calcining at 500°C for 6 hours to prepare alumina-titania and ZSM-5 powder composite carrier. Alumina-titania accounts for 40% by weight, and ZSM-5 powder accounts for 60% by weight.

[0036]Add 62.7g of nickel nitrate to 100ml of water, stir and dissolve, adjust the pH value to 5, impregnate on 100g of carrier 1, dry at 120°C for 6 hours, and then roast at 600°C for 5 hours to obtain the catalyst. The nickel oxide content is 16% by weight.

Embodiment 3

[0038] The preparation method of alumina-titanium oxide is the same as that of Example 1, and then the prepared 60g of alumina-titanium oxide and 40g of ZSM-5 powder are mixed, and a certain amount of 2% dilute nitric acid solution is added, and after kneading and extruding, the Drying at 110°C for 12 hours and calcining at 500°C for 6 hours to prepare alumina-titania and ZSM-5 powder composite carrier. Alumina-titania accounts for 60% by weight, and ZSM-5 powder accounts for 40% by weight.

[0039] Add 78.4g of nickel nitrate to 100ml of water, stir and dissolve, adjust the pH value to 5, impregnate on 100g of carrier 1, dry at 120°C for 6 hours, and then roast at 600°C for 5 hours to obtain the catalyst. The nickel oxide content is 20% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com