Olefin polymerization catalyst component preparation method and corresponding catalyst

A technology for olefin polymerization and catalyst, which is applied in the petrochemical field and can solve problems such as ligand compounds that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

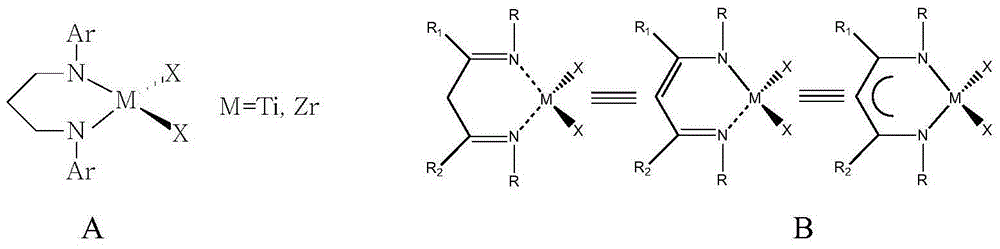

AI Technical Summary

Problems solved by technology

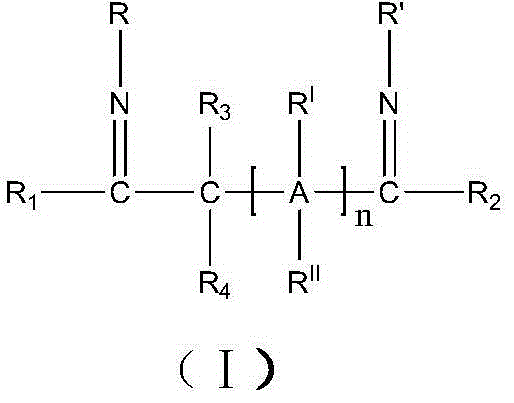

Method used

Image

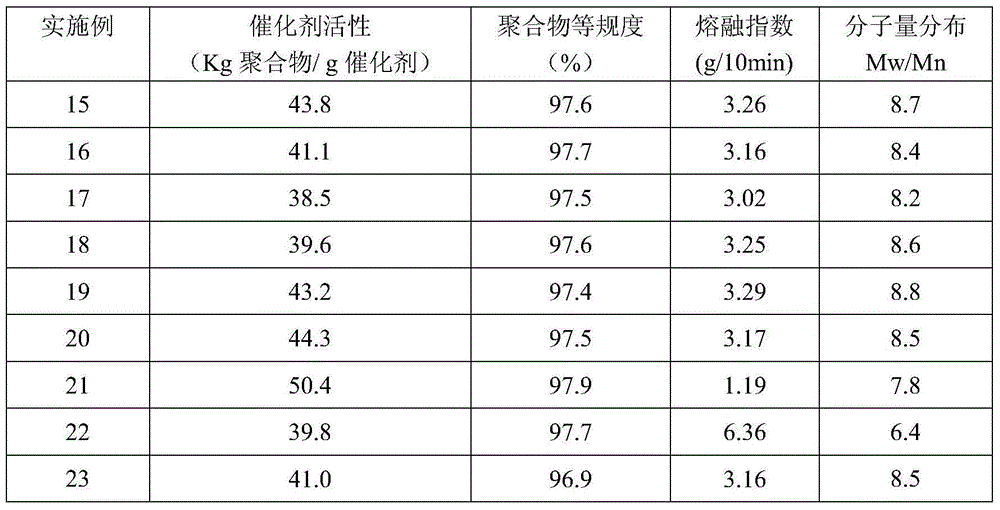

Examples

Embodiment 1

[0048] The synthesis of embodiment 1 compound 2,4-two (2,6-diisopropylphenylimino) pentane

[0049] In a three-neck flask, 1.00 g of acetylacetone, 40 ml of isopropanol and 0.2 ml of glacial acetic acid were added after purging with nitrogen, and stirred evenly at room temperature. At room temperature, a solution of 3.68 g of 2,6-diisopropylaniline in 50 ml of isopropanol was slowly added dropwise. After the addition was completed, the mixture was stirred for 1 hour and then heated to 100° C. for reflux for 26 hours. The reaction solution was concentrated under reduced pressure and separated by column chromatography to obtain 2.80 g of light yellow liquid (67% yield). 1 H-NMR (δ, ppm, TMS, CDCl 3 ):7.63~7.46(3H,m,ArH),3.25~3.38(6H,m,CH and CH 2 ),1.21~1.38(27H,m,CH 3 ),0.98~1.12(3H,m,CH 3 ); mass spectrometry, FD-massspectrometry: 418.

Embodiment 2

[0050] The synthesis of embodiment 2 compound 2,4-two (2,6-dimethylbenimino) pentane

[0051] In a three-necked flask, 1.00 g of acetylacetone, 80 ml of isopropanol and 0.2 ml of glacial acetic acid were added after purging with nitrogen, and stirred evenly at room temperature. At room temperature, a solution of 2.46 g of 2,6-dimethylaniline in 30 ml of isopropanol was slowly added dropwise. After the addition was completed, the mixture was stirred for 0.5 hours and then heated to 90° C. for reflux for 24 hours. The reaction solution was concentrated and separated by column chromatography to obtain 2.72 g of light yellow liquid (67% yield). 1 H-NMR (δ, ppm, TMS, CDCl 3 ):7.72~7.53(3H,m,ArH),3.25~3.31(2H,m,CH 2 ),2.31~2.54(12H,m,CH 3 ),1.20~1.35(3H,m,CH 3 ),0.98~1.12(3H,m,CH 3 ); mass spectrometry, FD-massspectrometry: 306.

Embodiment 3

[0052] The synthesis of embodiment 3 compound 2,4-two (2,4,6-trimethylbenimino) pentane

[0053] In a three-neck flask, 1.00 g of acetylacetone, 40 ml of absolute ethanol and 0.5 ml of glacial acetic acid were added after purging with nitrogen, and stirred evenly at room temperature. At room temperature, a solution of 2.73 g of 2,4,6-trimethylaniline in 50 ml of ethanol was slowly added dropwise. After the addition was completed, the mixture was stirred for 1 hour and then heated to 100° C. for reflux for 36 hours. The reaction solution was concentrated under reduced pressure and separated by column chromatography to obtain 2.07 g of product (62% yield). 1 H-NMR (δ, ppm, TMS, CDCl 3 ):7.86~7.66(4H,m,ArH),3.16~3.28(2H,m,CH 2 ),2.30~2.52(18H,m,CH 3 ),1.21~1.34(3H,m,CH 3 ),0.98~1.14(3H,m,CH 3 ); mass spectrometry, FD-massspectrometry: 334.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com