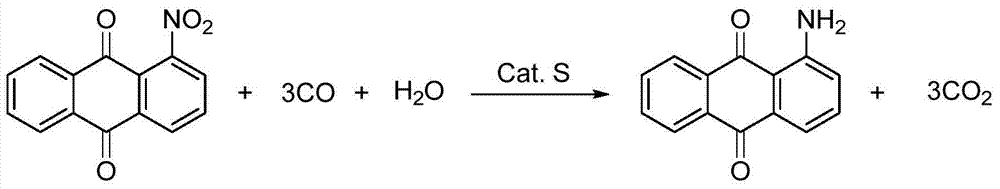

A method for synthesizing 1-aminoanthraquinone

A technology of aminoanthraquinone and nitroanthraquinone, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high initial reaction cost, complicated method, and low feeding amount, and achieves the difficulty of reaction process. Low, simple raw materials, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In a 1000ml autoclave equipped with a stirring bar, add 1-nitroanthraquinone (110g), sulfur powder (1g), H 2 O (400ml), NaHCO 3 (20g), the pH value of the reaction system was about 8; carbon monoxide was introduced to 5MPa, then heated to 150°C and stirred for 4 hours, cooled to room temperature, suction filtered, and dried to obtain the target product 1-aminoanthraquinone. The product was analyzed by high performance liquid chromatography and the yield was 98.5%.

Embodiment 2

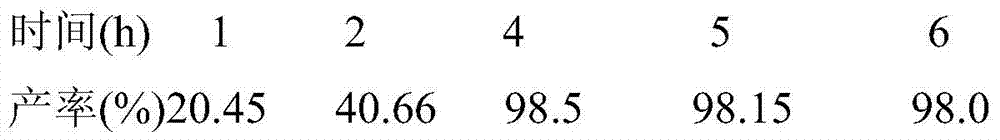

[0032] Other experimental method and condition are the same as embodiment 1, only change time, record 1-aminoanthraquinone productive rate as follows:

[0033]

Embodiment 3

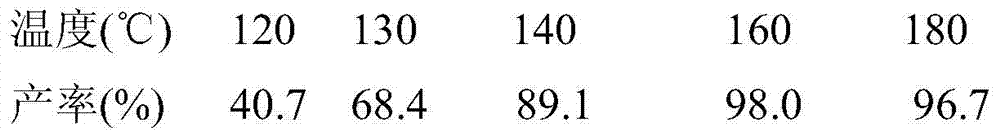

[0035] Other experimental method and condition are the same as embodiment 1, only change temperature, record 1-aminoanthraquinone productive rate as follows:

[0036]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com