Method for treating pyridine wastewater

A treatment method, pyridine technology, applied in natural water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high treatment cost, polluted environment, and high cost of pyridine production wastewater incineration treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

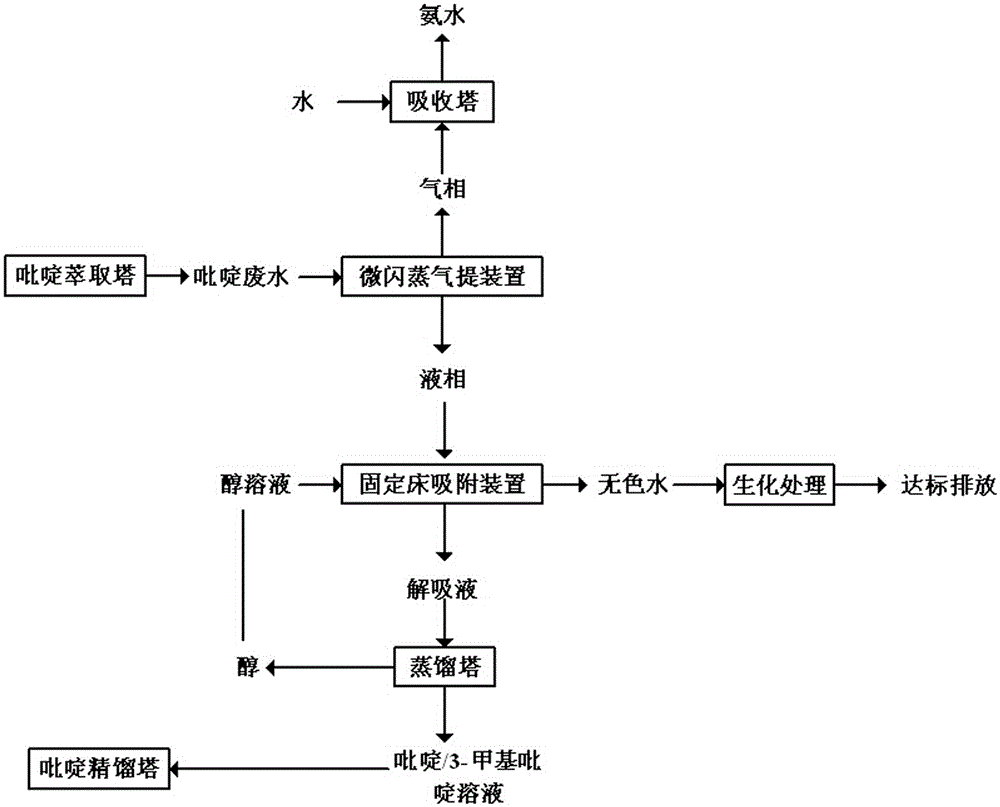

Method used

Image

Examples

Embodiment 1

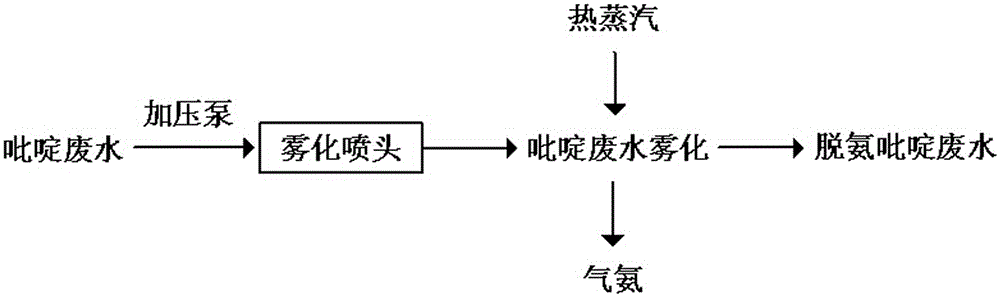

[0029] (1) Low vacuum flash stripping

[0030] In the process of high-temperature synthesis of pyridine using acetaldehyde + formaldehyde + liquid ammonia, the red pyridine waste water discharged from the pyridine extraction tower with a COD of 25000mg / L, consisting of 5000ppm pyridine / 3-picoline, 5% ammonia and water, is pressurized Pumped into a low-vacuum flash stripping device for separation, the pressure was controlled at 0.1 MPa, and the temperature was 95°C to obtain gas-phase ammonia and liquid-phase pyridine and 3-picoline solutions with a pH of 9.5;

[0031] (2) gas phase absorption

[0032] The gas phase ammonia obtained in step (1) is sent to the absorption tower for absorption, the pressure in the tower is controlled to 0.03MPa, the temperature is 20°C, and water is used as the absorbent to obtain ammonia water, which is reused in the pyridine production process;

[0033] (3) Fixed bed adsorption

[0034] The liquid phase pyridine and 3-picoline solution obtaine...

Embodiment 2

[0041] (1) Low vacuum flash stripping

[0042] In the process of high-temperature synthesis of pyridine using acetaldehyde + formaldehyde + liquid ammonia, the red pyridine waste water discharged from the pyridine extraction tower with a COD of 27000mg / L, consisting of 6000ppm pyridine, 3-picoline, 6% ammonia and water, is pressurized Pumped into a low-vacuum flash stripping device for separation, the control pressure of the atomization chamber is 0.01MPa, and the temperature is 80°C to obtain gas-phase ammonia and liquid-phase pyridine and 3-picoline solutions with a pH of 8.0;

[0043] (2) gas phase absorption

[0044] The gas phase ammonia obtained in the step (1) is sent to the absorption tower for absorption, the 0.05MPa in the tower is controlled, the temperature is controlled at 25°C, and water is used as the absorbent to obtain ammonia water, which is reused in the pyridine production process;

[0045] (3) Fixed bed adsorption

[0046] The liquid phase pyridine / 3-pic...

Embodiment 3

[0053] (1) Low vacuum flash stripping

[0054] In the process of high-temperature synthesis of pyridine using acetaldehyde + formaldehyde + liquid ammonia, the red pyridine wastewater discharged from the pyridine extraction tower with a COD of 29000mg / L, consisting of 7000ppm pyridine, 3-picoline, 5.5% ammonia and water, is pressurized Pumped into a low-vacuum flash stripping device for separation, the control pressure of the atomization chamber is 0.02MPa, and the temperature is 90°C to obtain gas-phase ammonia and liquid-phase pyridine and 3-picoline solutions with a pH of 7;

[0055] (2) gas phase absorption

[0056] The gas phase ammonia obtained in the step (1) is sent to the absorption tower for absorption, the pressure in the tower is controlled to 0.02MPa, the temperature is controlled at 20°C, and water is used as the absorbent to obtain ammonia water, which is reused in the pyridine production process;

[0057] (3) Fixed bed adsorption

[0058] The liquid phase pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com