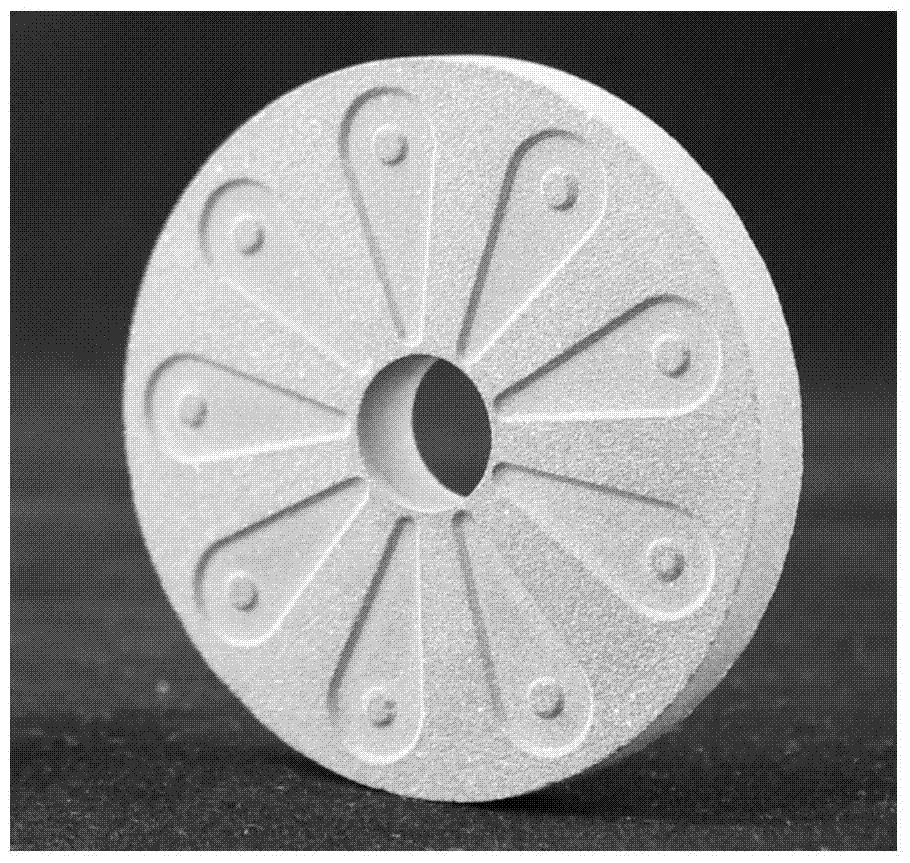

Manufacture of hydrogen-rich water alloy ceramic material and its preparation method and application

A hydrogen-rich water alloy and ceramic material technology, applied in chemical instruments and methods, water/sewage treatment, light water/sewage treatment, etc., can solve problems such as easy precipitation of precipitates, excessive magnesium ions, easy dissolution of magnesium ions, etc. To achieve the effect of increasing the specific surface area, increasing product life, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

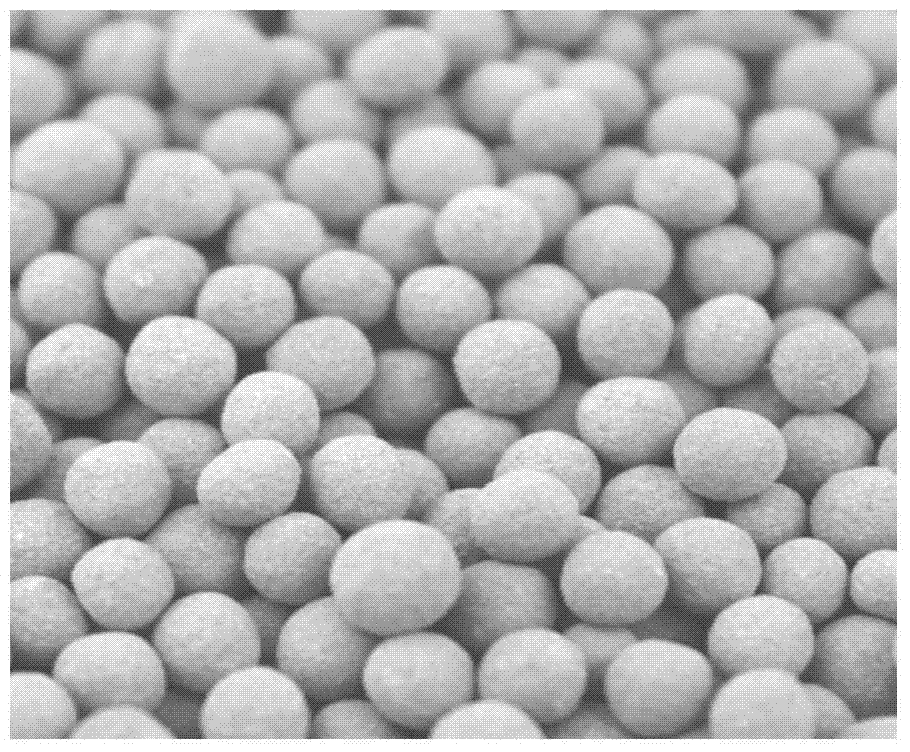

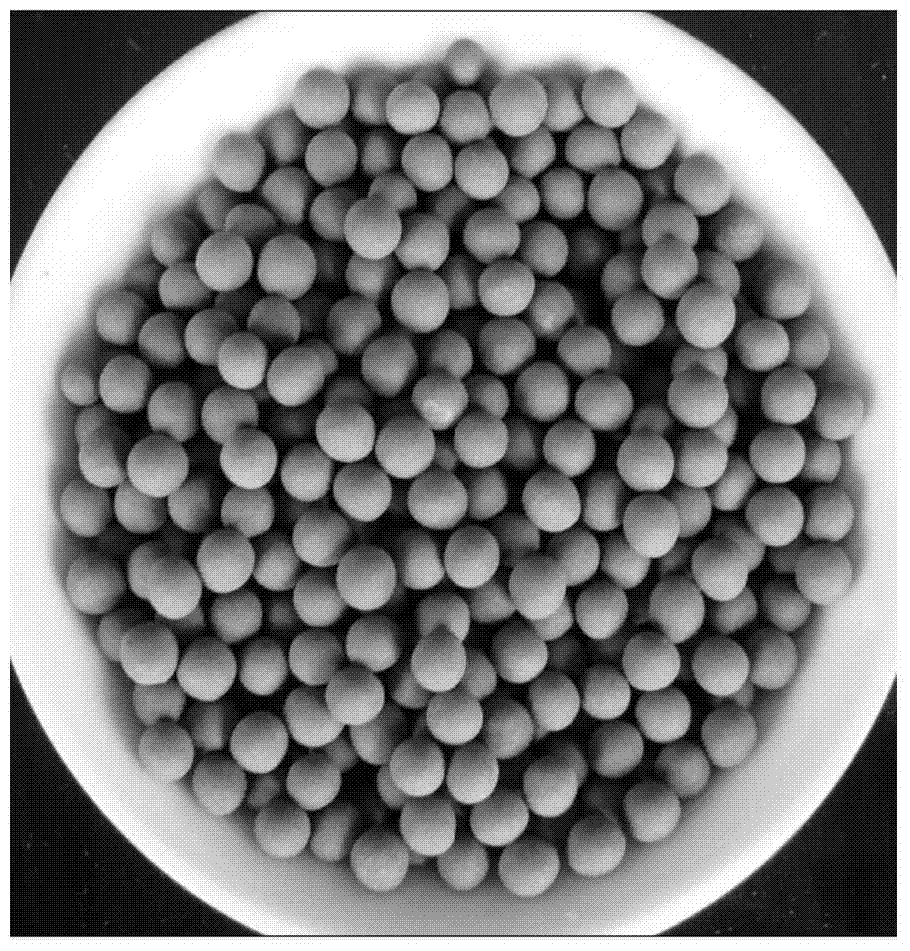

[0068] The hydrogen-rich water alloy ceramic material is made of the following raw materials in parts by weight:

[0069] 57 parts of substrate components, 40 parts of hydrogen-rich components, 13 parts of antibacterial components and 16 parts of binders;

[0070] The base material component is made of raw materials in the following weight percentages:

[0071] Tourmaline 32%, Hydrostone 20%, Silicon Oxide 28%, Calcium Oxide 10%, and Zeolite 10%.

[0072] The hydrogen-rich component is made of raw materials in the following weight percentages:

[0073] Metal magnesium powder 30%, magnesium oxide powder 20% and KDF alloy powder 50%.

[0074] Described antibacterial component is made of the raw material of following percentage by weight:

[0075] Zinc oxide 20%, titanium oxide 50% and cerium oxide 30%.

[0076] Described binding agent is made by the raw material of following percentage by weight:

[0077] High-purity distilled water 30%, carboxypropyl cellulose 30% and bent...

Embodiment 2

[0090] The hydrogen-rich water alloy ceramic material is made of the following raw materials in parts by weight:

[0091] 60 parts of substrate components, 50 parts of hydrogen-rich components, 20 parts of antibacterial components and 12 parts of binder;

[0092] The base material component is made of raw materials in the following weight percentages:

[0093] Tourmaline 25%, Hydrostone 10%, Silicon Oxide 20%, Calcium Oxide 20%, and Zeolite 25%.

[0094] The hydrogen-rich component is made of raw materials in the following weight percentages:

[0095] Metal magnesium powder 40%, magnesium oxide powder 20% and KDF alloy powder 40%.

[0096] Described antibacterial component is made of the raw material of following percentage by weight:

[0097] Zinc oxide 30%, titanium oxide 50% and cerium oxide 20%.

[0098]Described binding agent is made by the raw material of following percentage by weight:

[0099] High-purity distilled water 40%, carboxypropyl cellulose 10% and benton...

Embodiment 3

[0112] The hydrogen-rich water alloy ceramic material is made of the following raw materials in parts by weight:

[0113] 40 parts of substrate components, 30 parts of hydrogen-rich components, 15 parts of antibacterial components and 20 parts of binders;

[0114] The base material component is made of raw materials in the following weight percentages:

[0115] Tourmaline 20%, Hydrostone 15%, Silicon Oxide 35%, Calcium Oxide 15%, and Zeolite 15%.

[0116] The hydrogen-rich component is made of raw materials in the following weight percentages:

[0117] Metal magnesium powder 50%, magnesium oxide powder 30% and KDF alloy powder 20%.

[0118] Described antibacterial component is made of the raw material of following percentage by weight:

[0119] Zinc oxide 40%, titanium oxide 40% and cerium oxide 20%.

[0120] Described binding agent is made by the raw material of following percentage by weight:

[0121] High-purity distilled water 50%, carboxypropyl cellulose 30% and bent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com