Flux-cored brazing rod with protective film and preparation method thereof

A technology of protective film and flux core, which is applied in welding equipment, manufacturing tools, welding medium, etc., can solve problems such as air hole defects of brazing joints, easy failure of flux core flux, slag inclusion in brazing joints, etc., and save storage costs , avoid moisture absorption, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of BAg45CuZn flux-cored brazing rod with protective film:

[0017] 1) Flux selection of 20% Na 2 B 4 o 7 +30% of B 2 o 3 +50% of KBF 4 formulated;

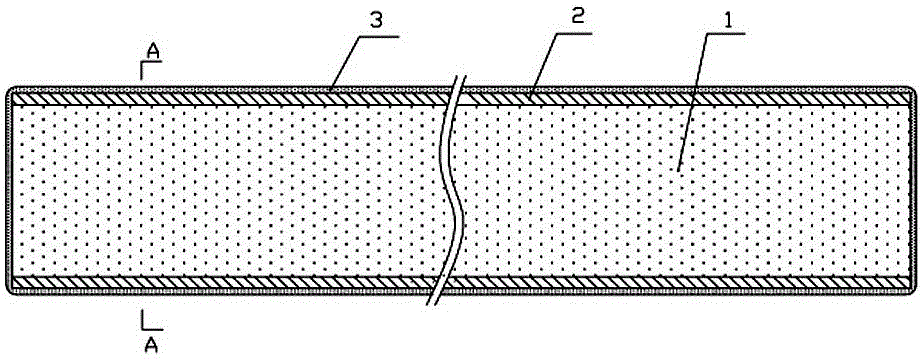

[0018] 2) The BAg45CuZn strip with a thickness of 0.25mm is made into a seamed flux-cored brazing rod with a diameter of 2.0mm and a length of 450mm through multiple rolling, powder feeding, drawing, and straightening processes;

[0019] 3) Mix the flux powder ground to a particle size of less than 120 mesh and the molten EVA adhesive curing agent at a ratio of 1:3, immerse the flux-cored brazing rod prepared in step 2) into the mixture, take it out at a uniform speed, and cool After curing, the finished BAg45CuZn flux-cored brazing rod with a protective film is obtained, and the thickness of the protective film is about 0.10mm.

[0020] The prepared flux-cored brazing rod with protective film and ordinary flux-cored solder without protective film were placed in the atmosphere for a week at the same time,...

Embodiment 2

[0022] Preparation of BAg30CuZn flux-cored brazing rod with protective film:

[0023] 1) Flux selection of 20% Na 2 B 4 o 7 +35% of B 2 o 3 +45% KBF 4 formulated;

[0024] 2) The BAg30CuZn strip with a thickness of 0.25mm is made into a seamed flux-cored brazing rod with a diameter of 2.0mm and a length of 450mm through multiple rolling, powder feeding, drawing, and straightening processes;

[0025] 3) Mix the flux powder ground to a particle size of less than 120 mesh and the molten EVA adhesive curing agent at a ratio of 1:2, and immerse the flux-cored brazing rod prepared in step 2) into the mixture, take it out at a constant speed, and cool After curing, the finished BAg30CuZn flux-cored brazing rod with a protective film is obtained, and the thickness of the protective film is about 0.12mm.

[0026] The prepared flux-cored brazing rod with protective film and ordinary flux-cored solder without protective film were placed in the atmosphere for a week at the same tim...

Embodiment 3

[0028] Preparation of BCu62Zn flux-cored brazing rod with protective film:

[0029] 1) Flux selection of 50% Na 2 B 4 o 7 +40% of B 2 o 3 +10% KBF 4 formulated;

[0030] 2) The BCu62Zn strip with a thickness of 0.25mm is made into a seamed flux-cored brazing rod with a diameter of 2.0mm and a length of 450mm through multiple rolling, powder feeding, drawing, and straightening processes;

[0031] 3) Mix the flux powder ground to a particle size of less than 120 mesh and the molten EVA adhesive curing agent at a ratio of 1:1, and immerse the flux-cored brazing rod prepared in step 2) into the mixture, take it out at a constant speed, and cool After curing, the finished BCu62Zn flux-cored brazing rod with a protective film is obtained, and the thickness of the protective film is about 0.13 mm.

[0032] The prepared flux-cored brazing rod with protective film and ordinary flux-cored solder without protective film were placed in the atmosphere for a week at the same time, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com