Reverse osmosis membrane and preparation method thereof

A reverse osmosis membrane and solution technology, applied in the field of membrane separation, can solve the problems that fullerenes cannot be recombined, and achieve the effect of improving water flux, salt interception rate and good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

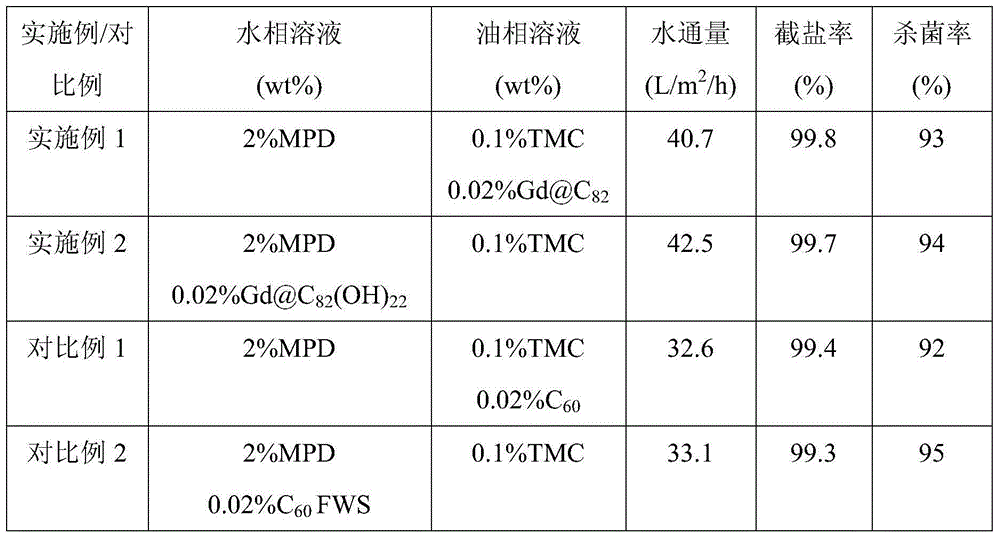

[0026] Embodiment and comparative example are the preparation of reverse osmosis membrane, wherein embodiment 1 adds GdC in the oil phase solution 82 , Embodiment 2 adds hydroxylated GdC in the aqueous phase solution 82 , Comparative Example 1 is adding C in the oil phase solution 60 , Comparative Example 2 is adding C in the aqueous phase solution 60 of aqueous suspension.

[0027] C in Examples 1 and 2 82 Prepared by arc method, the specific steps are: high-purity graphite (purity>99.9%) and Gd 2 o 3 Mix thoroughly at a molar ratio of 1:25, add adhesive phenolic resin to form a film, and sinter in a high-temperature furnace at 1600 ° C. The fired graphite rod is discharged on a DC arc device to synthesize black soot. After solvent extraction with methylformamide (DMF), GdC was separated by HPLC 82 , with a purity of >99.9%.

Embodiment 2

[0028]GdC in Example 2 82 The specific steps of hydroxylation are: GdC with a concentration of 0.05mg / ml 82 The toluene solution and the NaOH aqueous solution with a mass fraction of 50% are mixed with a volume of 10:1, and the volume is 5% of the mixed solution, and tetrabutylammonium hydroxide (TBAH) with a mass fraction of 10% is used as a catalyst, and the reaction is stirred for 2 hours to remove colorless The toluene layer, the water layer was washed 3 times with toluene to remove unreacted GdC 82 , and then the water layer was evaporated to obtain a brown precipitate, which was dissolved in water and separated by Sephadex-25 chromatography column to obtain yellow hydroxylated GdC 82 . MALDI-TOF mass spectrometry showed that the prepared GdC 82 and GdC 82 (OH) 22 To compare the pure substances, infrared spectroscopy (IR) and X-ray photoelectron spectroscopy (XPS) show that the chemical formula of the hydroxylated metallofullerene is GdC 82 (OH) 22 .

[0029] C in...

Embodiment 1

[0031] A. Preparation of aqueous phase solution: m-phenylenediamine was dissolved and dispersed in ultrapure water to prepare an aqueous phase solution with a mass fraction of 2%.

[0032] B. Preparation of oil phase solution: Dissolve and disperse trimesoyl chloride in dodecane to prepare an oil phase solution with a mass fraction of 0.1%.

[0033] C. GdC 82 Dissolved in the oil phase solution, ultrasonically dispersed to make it uniform, the mass fraction is 0.02%.

[0034] D. Interfacial polymerization: Immerse the polysulfone support membrane in the above-mentioned prepared water phase solution, remove the remaining water phase solution after taking it out, and then contact the surface of the support membrane with the oil phase solution on one side to carry out interfacial polymerization reaction, the obtained After the nascent hybrid reverse osmosis membrane is taken out, it is dried in an oven at 70°C for 5 minutes, taken out, and then stored in ultrapure water.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com