ge/geo for lithium-ion batteries 2 ‑Mesoporous carbon composite electrode material preparation and application

A lithium-ion battery and composite electrode technology, which is applied in the field of power lithium-ion battery materials, can solve the problems of poor conductivity, volume change, and poor cycle performance, and achieve high-rate charge and discharge characteristics, good application prospects, and long cycle life. Effect of Discharge Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, 10 grams of mesoporous carbon was refluxed with 26% nitric acid at 60° C. for 1 hour. Disperse 36 grams of germanium chloride in an appropriate amount of ethanol with a concentration of 95% by volume, stir with a magnetic stirrer for 20 minutes, then add mesoporous carbon with a concentration of 26% by weight of nitric acid, stir, and ultrasonically 5 minutes, and dried at 70° C. for 2 hours to obtain a powder. The resulting powder was then placed in 5% H 2 / 95% Ar atmosphere tube furnace and calcined at 600℃ for 6 hours to obtain Ge / GeO 2 - Mesoporous carbon composites.

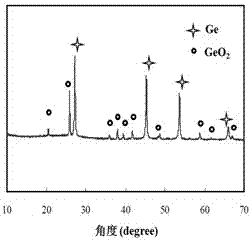

[0033] Obtained by XRD experiment as figure 1 Ge / GeO shown 2 - XRD patterns of mesoporous carbon composites, by figure 1 It can be seen that the synthesis of Ge and GeO 2 The complex, its diffraction peak position and the standard spectrum of Ge (JCPDS, 089-2768) and GeO 2 The standard map (JCPDS, 036-1463) matches.

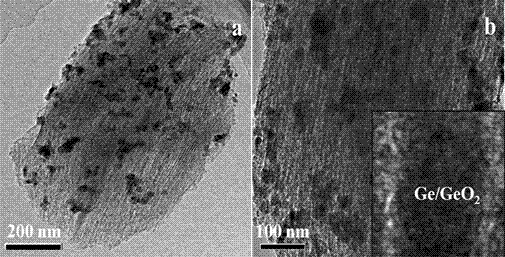

[0034] obtained by transmission electron microscopy figure 2 shown ...

Embodiment 2

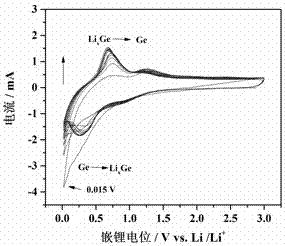

[0038] First, 20 g of mesoporous carbon was refluxed with 15% nitric acid at 70° C. for 0.5 hour. Disperse 40 grams of germanium hydroxide in an appropriate amount of ethanol with a concentration of 95% by volume, stir with a magnetic stirrer for 10 minutes, then add the above-mentioned mesoporous carbon treated with nitric acid, stir and ultrasonic for 8 minutes, and dry at 60°C A powder was obtained in 3 hours. The resulting powder was then placed in 5% H 2 / 95%Ar atmosphere tube furnace calcined at 700℃ for 4 hours to obtain Ge / GeO 2 - Mesoporous carbon composites. Lithium-ion battery assembly: by mass ratio Ge / GeO 2 - Mesoporous carbon composite: polytetrafluoroethylene: acetylene black = 90:10:5 mixed and ground and evenly coated on the copper foil as the positive electrode, the reference electrode and the counter electrode are metal lithium, and the electrolyte is made of 1M LiPF 6 EC+DMC+EMC (EC / DMC / EMC =1 / 1 / 1 v / v / v) solution. All assembly takes place in the glove ...

Embodiment 3

[0042] First, 50 g of mesoporous carbon was refluxed for 2 hours at 50°C with 20% by weight nitric acid. Disperse 230 grams of carboxyethyl germanium in an appropriate amount of ethanol with a concentration of 95% by volume, stir with a magnetic stirrer for 20 minutes, then add the above-mentioned mesoporous carbon treated with nitric acid, stir and ultrasonic for 10 minutes, and bake at 50 ° C Dry for 4 hours to obtain a powder. The resulting powder was then placed in 5% H 2 / 95%Ar atmosphere tube furnace calcined at 700℃ for 2 hours to obtain Ge / GeO 2 - Mesoporous carbon composites. Lithium-ion battery assembly: by mass ratio Ge / GeO 2 - Mesoporous carbon composite: polytetrafluoroethylene: acetylene black = 83:15:5 mixed and ground, and evenly coated on copper foil as the positive electrode, the counter electrode is graphite carbon, and the electrolyte is made of 1M LiPF 6 EC+DMC+EMC (EC / DMC / EMC =1 / 1 / 1 v / v / v) solution. All assembly takes place in the glove box.

[0043...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com