Preparation method of high-performance lithium ion power battery/porous carbon composite positive electrode material

A technology of composite positive electrode material and power battery, which is applied in the field of power lithium-ion battery materials to achieve the effects of good reproducibility, excellent performance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

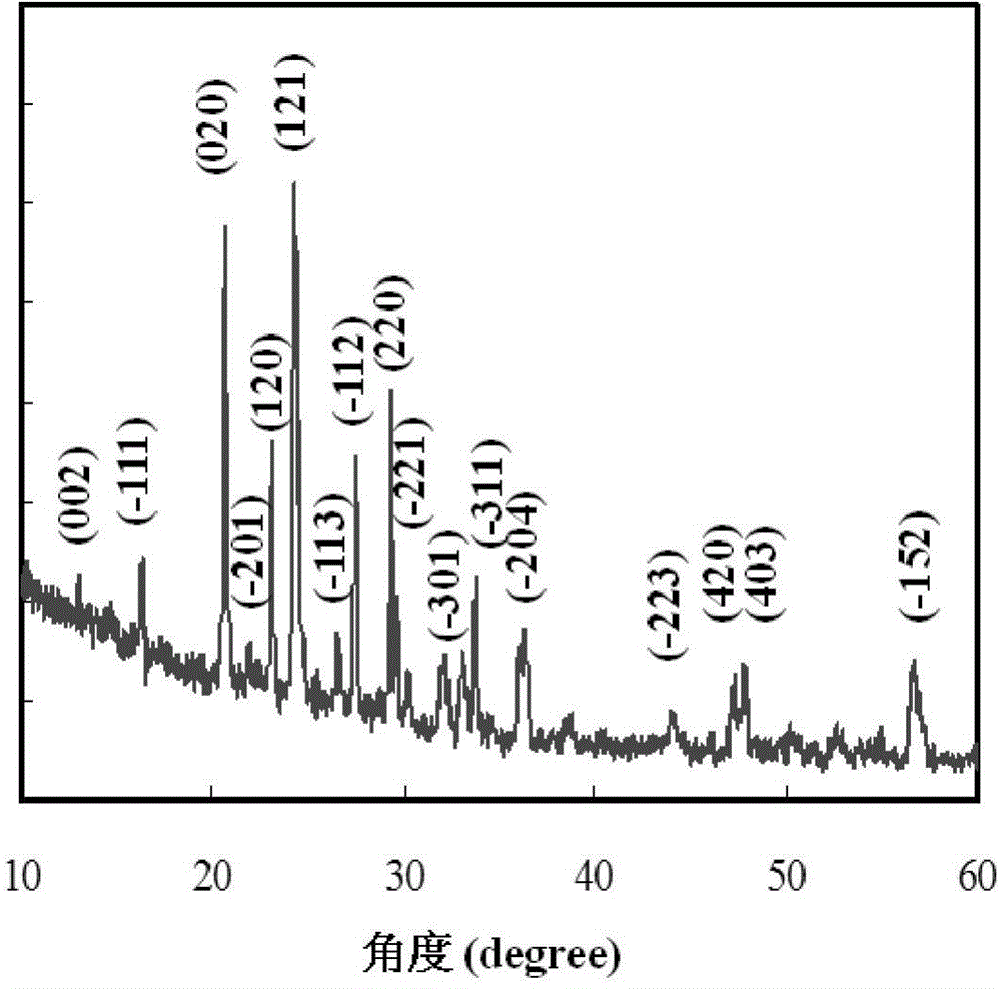

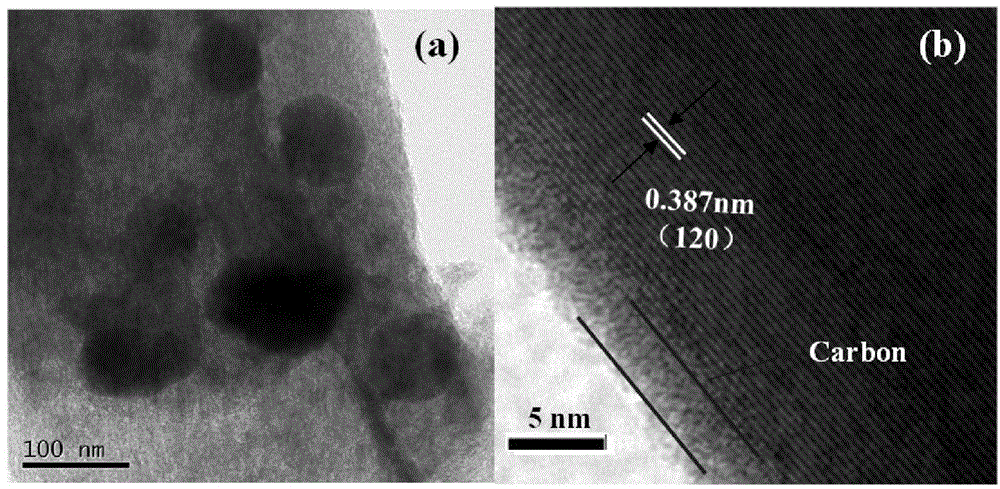

[0026] Firstly, the porous carbon (product number XFPO2 produced by Nanjing Nanometer Xianfeng Co., Ltd.) was refluxed with 30% by weight nitric acid at 70°C for 0.5 hours. Add lithium carbonate, ammonium metavanadate, ammonium dihydrogen phosphate and citric acid in a molar ratio of 3:2:3:2 to the reactor, add an appropriate amount of deionized water and ethanol with a concentration of 95% by volume, and use a magnetic stirrer After stirring for 30 minutes, the above-mentioned porous carbon treated with nitric acid was added, stirred, ultrasonicated for 20 minutes, and dried at 60° C. for 3 hours to obtain a powder. The resulting powder was then placed in N 2 Li 3 V 2 (PO 4 ) 3 / porous carbon composite. Obtained by XRD experiment figure 1 Li 3 V 2 (PO 4 ) 3 / XRD pattern of porous carbon composite cathode material, by figure 1 It can be seen that the synthesis of high crystallinity lithium vanadium phosphate has the same diffraction peak position as the monoclinic ...

Embodiment 2

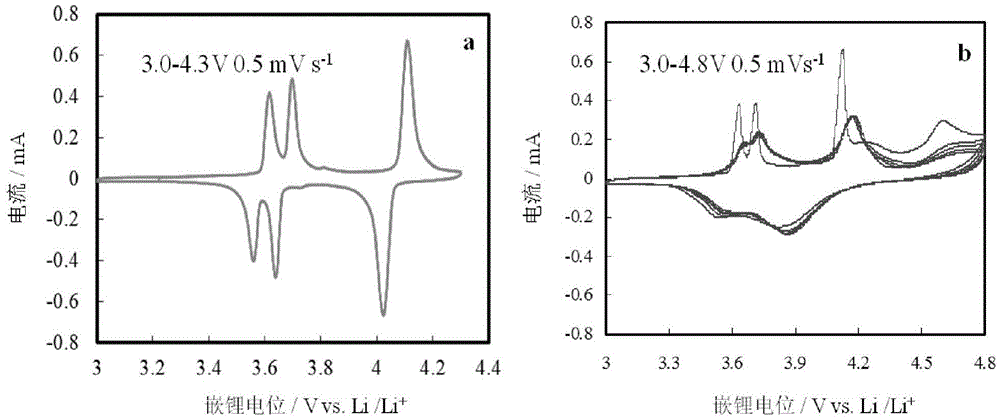

[0028] Firstly, the porous carbon (product No. XFPO2 produced by Nanjing Nanometer Xianfeng Co., Ltd.) was refluxed with nitric acid with a concentration of 15% by weight at 60°C for 1 hour. Add lithium acetate, ammonium metavanadate, ammonium dihydrogen phosphate and citric acid in a molar ratio of 3:2:3:1.5 into the reactor, add an appropriate amount of deionized water and ethanol with a concentration of 95% by volume, and use a magnetic stirrer to After stirring for 10 minutes, the porous carbon treated with nitric acid was added, stirred, ultrasonicated for 30 minutes, and dried at 80° C. for 1 hour to obtain a powder. The resulting powder was then placed in N 2 Li 3 V 2 (PO 4 ) 3 / porous carbon composite. Lithium-ion battery assembly: by mass ratio Li 3 V 2 (PO 4 ) 3 / Porous carbon composite: polytetrafluoroethylene: acetylene black = 80:10:10 mixed and ground, evenly coated on the aluminum foil as the positive electrode, the reference electrode and the counter...

Embodiment 3

[0030] Firstly, the porous carbon (product number XFPO2 produced by Nanjing Nanometer Xianfeng Co., Ltd.) was refluxed with 20% by weight nitric acid at 60°C for 1 hour. Add lithium nitrate, ammonium metavanadate, ammonium dihydrogen phosphate and citric acid in a molar ratio of 3:2:3:2.5 into the reactor, add an appropriate amount of deionized water and ethanol with a concentration of 95% by volume, and use a magnetic stirrer to After stirring for 10 minutes, the porous carbon treated with nitric acid was added, stirred, ultrasonicated for 30 minutes, and dried at 70° C. for 2 hours to obtain a powder. The resulting powder was then placed in N 2 Li 3 V 2 (PO 4 ) 3 / porous carbon composite. Lithium-ion battery assembly: by mass ratio Li 3 V 2 (PO 4 ) 3 / Porous carbon composite: polytetrafluoroethylene: acetylene black = 80:15:5 mixed and ground, evenly coated on the aluminum foil as the positive electrode, the counter electrode is graphite carbon, and the electrolyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com