Production line for continuously casting and fragmenting storage battery plate grid

A production line and battery technology, which is applied in the field of battery continuous grid slicing production line, can solve the problems of increasing the import cost of enterprises, and achieve the effect of improving the labor environment, reducing the import cost, and saving energy and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

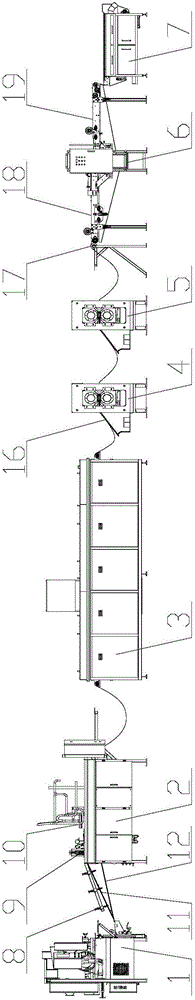

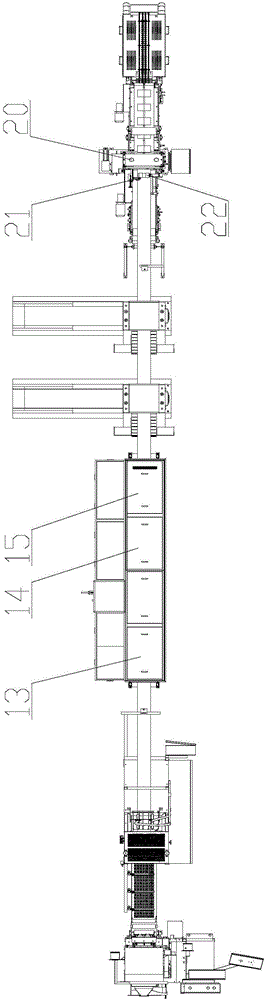

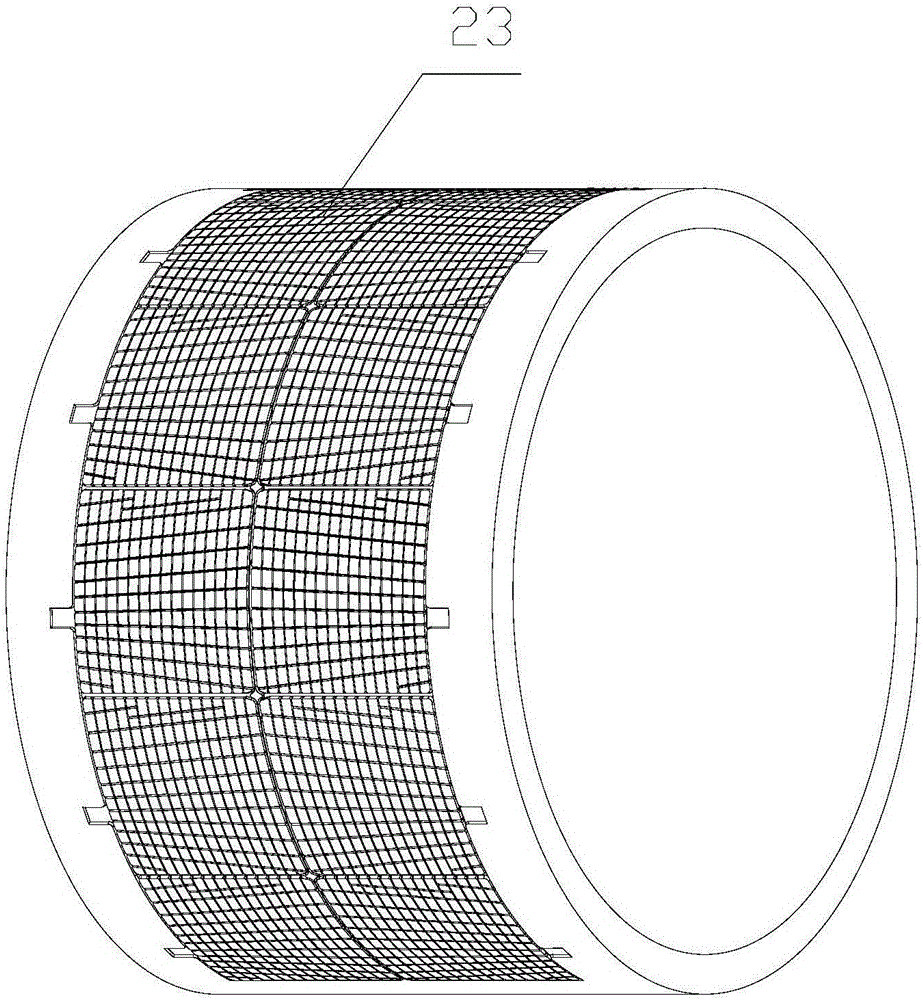

[0020] figure 1 It is a schematic diagram of equipment layout of the present invention; figure 2 for figure 1 top view of image 3 It is a schematic diagram of the dynamic model; Figure 4 It is a schematic diagram of the fixed mold; Figure 5 It is a structural schematic diagram of the rolling shear main engine, as shown in the figure: the battery grid continuous casting and slicing production line of this embodiment includes a continuous casting machine 1, a tractor 2, a cleaning machine 3, a coarse Rolling mill 4, finishing mill 5, rolling shear splitter 6 and lamination stacker 7; the continuous casting machine 1 is a dynamic and fixed mode grid continuous casting machine, and the cast grid is a continuous grid; The main machine of the rolling shear slicing machine is a double-roller rolling shear device equipped with an upper knife roller 25 and a lower support roller 26, which is used to accurately cut the cast continuous grid without coating, that is, the grid mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com