Modified diatomite carried immobilized spore laccase as well as preparation method and application thereof

A technology of spore laccase and diatomite, which is applied to chemical instruments and methods, immobilized on or in inorganic carriers, water pollutants, etc., can solve problems such as inability to immobilize spores, and achieves low production cost and abundant resources. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

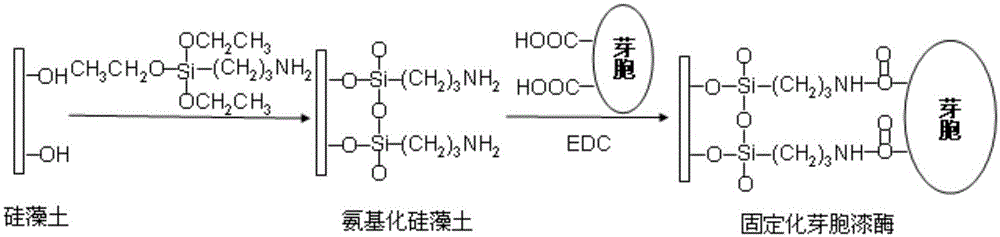

[0047] Embodiment 1 diatomaceous earth amination and spore laccase immobilization method 1

[0048] Weigh 2g of diatomaceous earth, pour it into 95ml of absolute ethanol, add 5ml of 3-aminopropyltriethoxysilane at the same time, shake the mixture, and treat it with ultrasonic wave for 30min. The above-treated mixture was treated at 70°C and 200r / min for 5h. The modified diatomite treated above was repeatedly washed and collected by filtration.

[0049] Dip the diatomite prepared above into 40ml potassium dihydrogen phosphate-dipotassium hydrogen phosphate buffer solution (pH7.0, 50mM), add 5ml carbodiimide hydrochloride (2mg / ml) and sonicate for 10min, then add 3ml of spore suspension (100mg / ml, wet weight) was ultrasonically treated for 30min, transferred to a shaker at 200r / min, and fixed at 37°C for 12h. Wash 3 times with buffer and collect by filtration. The recovery rate of enzyme activity was measured to be 82.29%.

Embodiment 2

[0050] Embodiment 2 diatomite amination and spore laccase immobilization method 2

[0051] Weigh 2g of diatomaceous earth, pour it into 48ml of absolute ethanol, add 2ml of 3-aminopropyltriethoxysilane at the same time, shake the mixture, and treat it with ultrasonic wave for 30min. The above-treated mixture was treated at 70°C and 200r / min for 12h. The modified diatomite treated above was repeatedly washed and collected by filtration.

[0052] Dip the diatomite prepared above into 40ml of potassium dihydrogen phosphate-dipotassium hydrogen phosphate buffer solution (pH7.0, 50mM), add 4ml of carbodiimide hydrochloride (4mg / ml) and sonicate for 10min, then add 2ml of spore suspension (100mg / ml, wet weight) was ultrasonically treated for 30min, transferred to a shaker at 200r / min, and fixed at 37°C for 12h. Wash 3 times with buffer and collect by filtration. The recovery rate of enzyme activity was measured to be 83.16%.

Embodiment 3

[0053] Embodiment 3 diatomite amination and spore laccase immobilization method 3

[0054] Weigh 5g of diatomaceous earth, pour it into 75ml of absolute ethanol, add 5ml of 3-aminopropyltriethoxysilane at the same time, shake the mixture, and treat it with ultrasonic wave for 30min. The above-treated mixture was placed at 70° C. and treated at 200 r / min for 10 h. The modified diatomite treated above was repeatedly washed and collected by filtration.

[0055] Dip the diatomite prepared above into 85ml of potassium dihydrogen phosphate-dipotassium hydrogen phosphate buffer solution (pH7.0, 50mM), add 10ml of carbodiimide hydrochloride (4mg / ml) and sonicate for 10min, then add 5ml of spore suspension (100mg / ml, wet weight) was ultrasonically treated for 30min, transferred to a shaker at 200r / min, and fixed at 37°C for 12h. Wash 3 times with buffer and collect by filtration. The recovery rate of enzyme activity was measured to be 67.44%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com