Method for preparing alkali-slag cement retarder through jarosite slag

A technology of slag cement and jarosite slag is applied in the field of preparing alkali-slag cement retarder to achieve the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A method for preparing alkali-slag cement retarder with jarosite slag, comprises the steps:

[0015] ①Add a dispersant to water, add alum slag and an oxidant, stir evenly, add lime, stir evenly, and let stand to separate the liquid and solid; ②Dry the solid phase to obtain a retarder; ③In the liquid phase The extractant is added to recover the silver metal, and the raffinate can be recycled as water in the step (1).

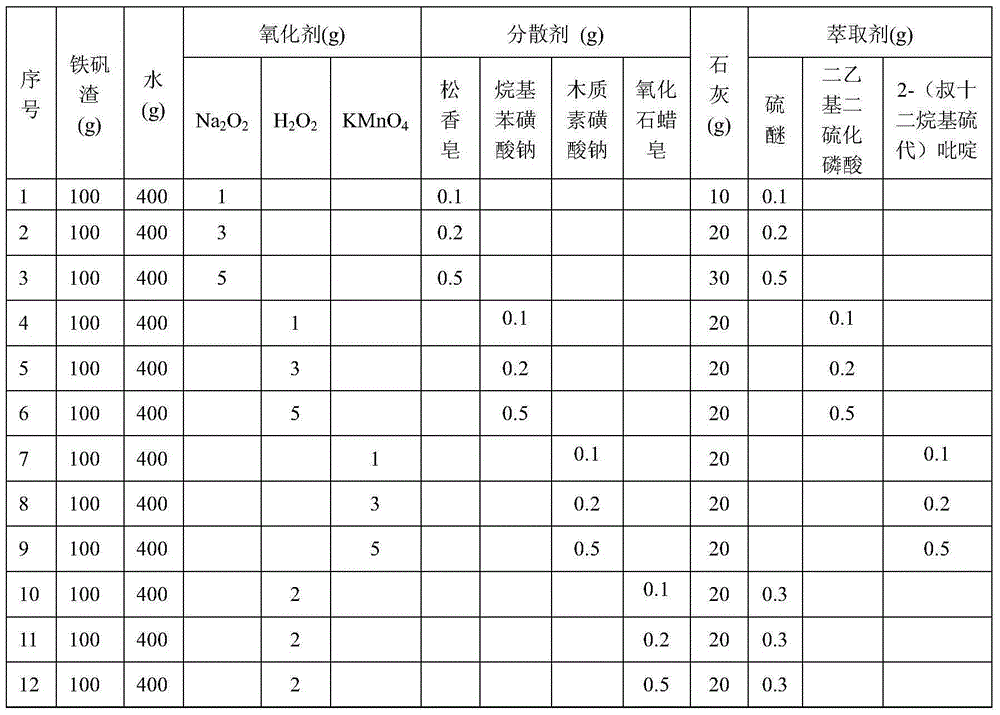

[0016] Wherein, reference table 1 is made for each component and addition amount of water, dispersant, jarosite slag, oxidizer, lime, extractant. Table 1 lists the formulation compositions of 12 examples numbered 1-12. After the retarder prepared by the method of the present invention is added to the alkali-slag cement, the initial setting time of the alkali-slag cement is measured according to the national standard "cement standard consistency water consumption, setting time, stability (GBT1346-2011)". All are greater than 60 minutes.

[0017]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com