Multi-stage transmission type polisher

A transmission type, finishing machine technology, which is applied in the direction of surface polishing machine tools, grinding drive devices, grinding machine parts, etc., which can solve the problem of low speed and slow working efficiency of finishing machines, and can only grind one workpiece at a time, etc. problems, to achieve the effect of shortening the grinding time, fast processing speed and sufficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

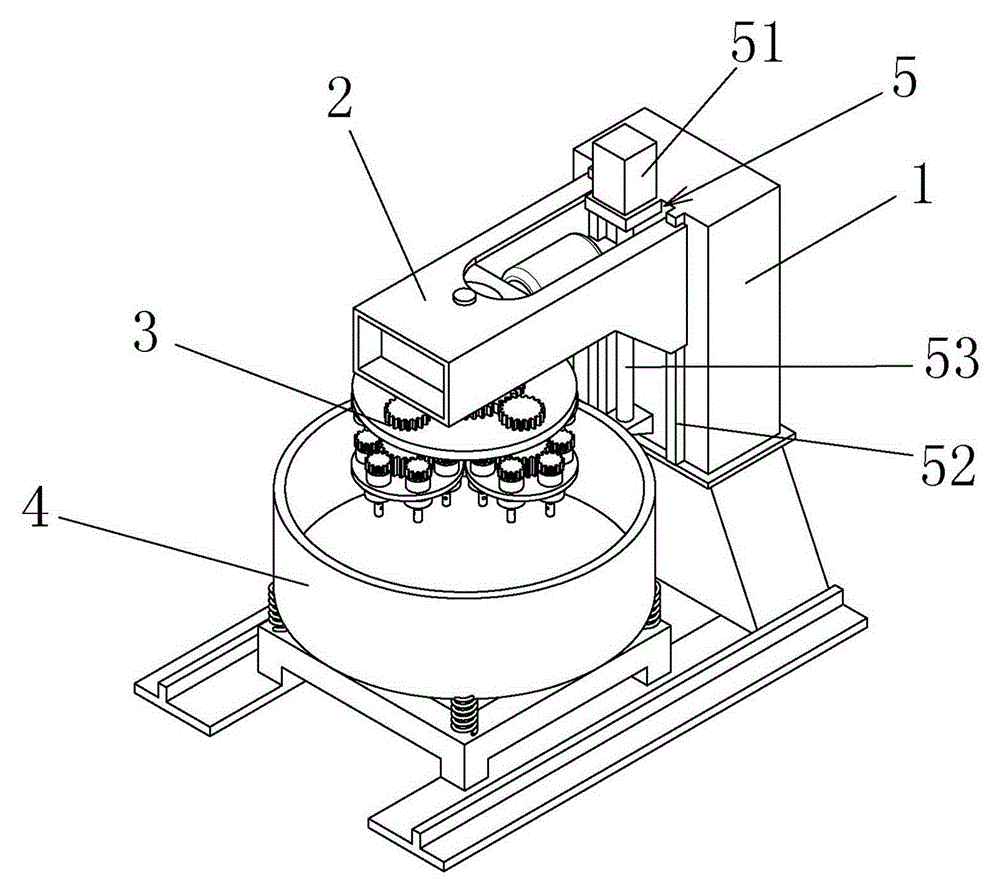

[0020] Embodiment 1: as Figure 1 to Figure 3 As shown, a multi-stage transmission finishing machine includes a column 1, a cross arm 2 and a grinding bucket 4, the cross arm 2 is connected with a lifting system 5, and the lifting system 5 includes a servo motor 51, a slide rail arranged on the column 1 52 and elevating rod 53, servo motor 51 drives elevating rod 53 to rotate and makes cross arm 2 do lifting motion along slide rail 52.

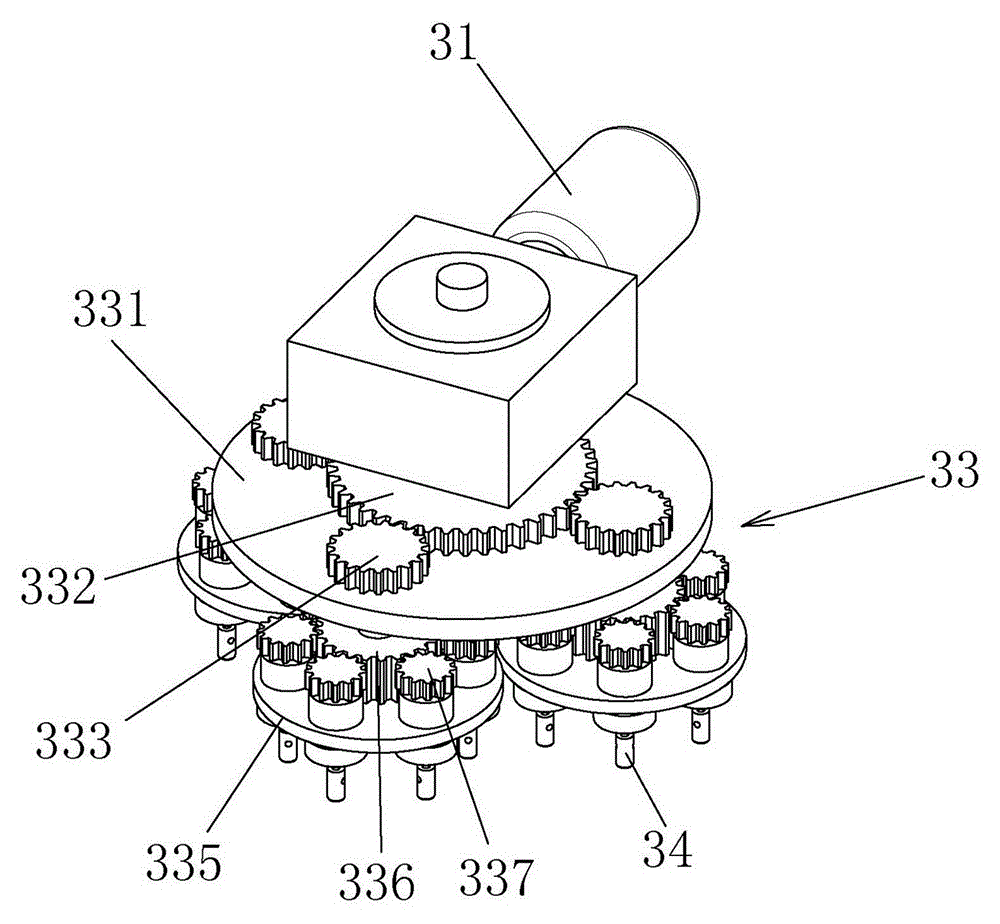

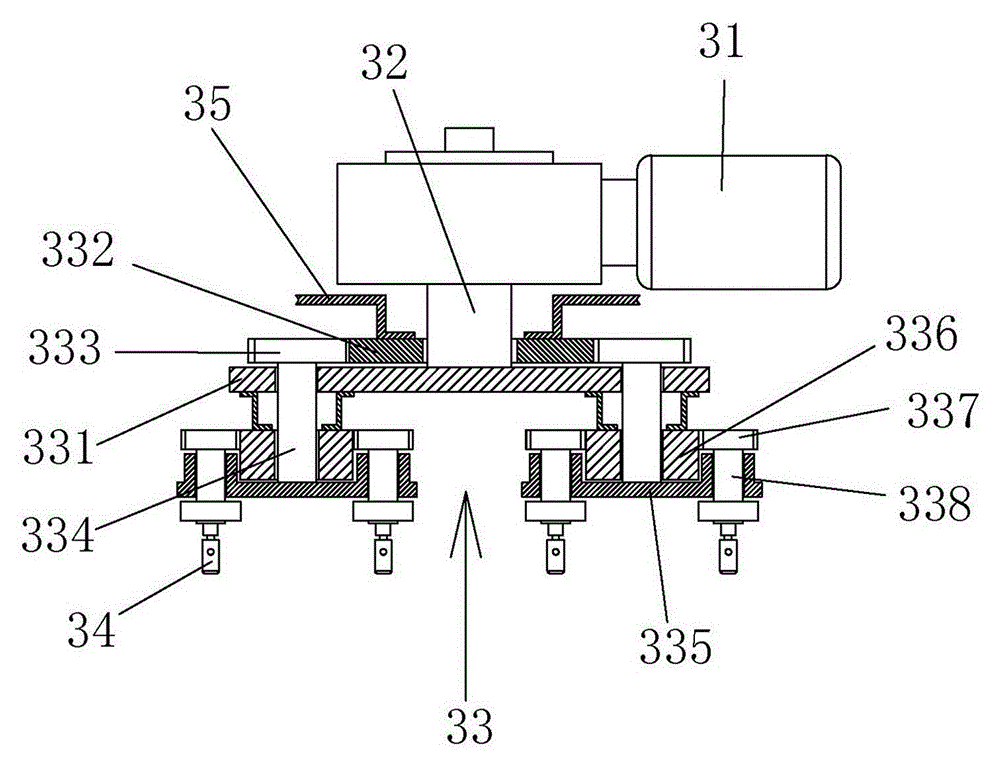

[0021] A grinding device 3 is provided on the cross arm 2 , and the grinding device 3 is located directly above the grinding barrel 4 . The grinding device 3 includes a driving motor 31, a main shaft 32, a rotating system 33 and a gripper 34. The rotating system 33 includes a primary planetary wheel rotating system and a secondary planetary wheel rotating system. The driving motor 31 drives the primary planetary wheel rotating system through the main shaft 32. Rotate, the primary planetary wheel rotating system drives the secondary planetary ...

Embodiment 2

[0025] Embodiment 2: as Figure 4 As shown, the difference from Embodiment 1 is that there are two first planetary gears 333 and four second planetary gears 337 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com