External transition belt grinding device for end upsetting of steel pipe

A pipe end thickening and transition zone technology, which is applied in the direction of grinding/polishing safety devices, grinding machines, metal processing equipment, etc., can solve the problems of potential safety hazards, unsuitable production and grinding, and low work efficiency, so as to shorten the grinding time, Effect of eliminating pollution and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

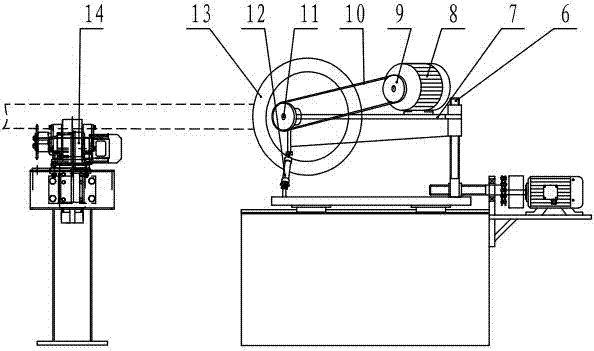

[0013] According to attached figure 1 and 2 It can be seen that the present invention specifically relates to an outer transition zone grinding device for thickening steel pipe ends, which belongs to steel pipe end processing equipment, and the equipment includes lifting and rotating rollers 14, a grinding device, an adjustment device, guide rails 17 and a dust collection box 16 The dust collection box 16 is an open casing, and the side of the dust collection box 16 is fixed with an adjustment device, and the other side of the dust collection box 16 opposite to the adjustment device is provided with a lift rotating roller 14 separated from the dust collection box 16, The guide rail 17 that other two sidewall upper surfaces of dust collection box 16 are provided with, is provided with grinding device on the guide rail 17; Rotating swivel support 7, the other end opposite corner point of swivel support 7 is provided with the cylinder 12 that adjusts the angle of swivel support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com