Weldless aluminum alloy lining neck-spinning method for large-diameter composite air cylinder

An aluminum alloy, no weld technology, applied in the field of aerospace composite gas cylinder manufacturing, can solve the problems of wrinkles, product scrap, composite gas cylinder leakage, etc., and achieves increased nozzle wall thickness, improved yield, improved The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

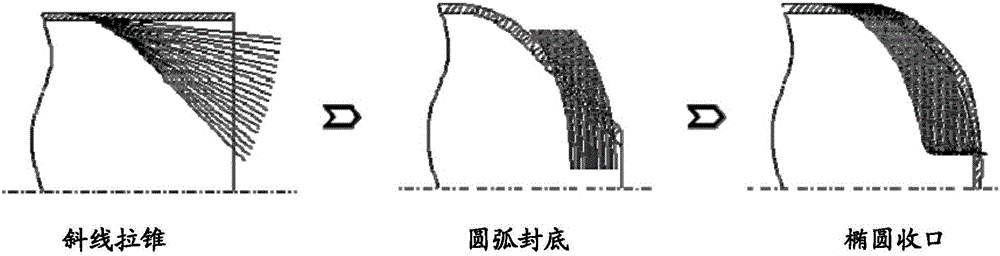

Method used

Image

Examples

Embodiment 1

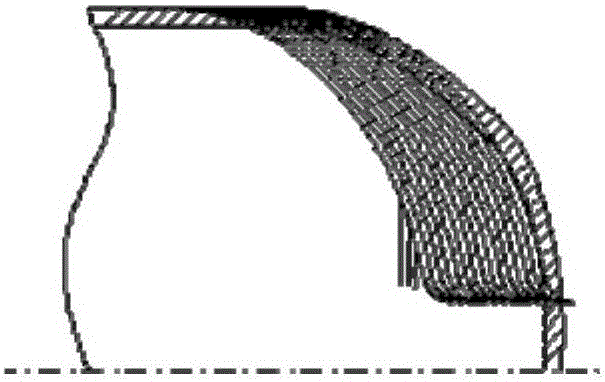

[0038] A specific example is given below. In this example, the cylindrical lining is 6061 aluminum alloy, the volume is 130L, the length is 1276mm, the length of the straight section is 862mm, the inner diameter is 404mm, and the wall thickness is 2mm. The head is ellipsoidal, and the head The semi-major axis of the inner surface is 200mm, the semi-minor axis is 143mm, the semi-major axis of the head profile is 202mm, the semi-minor axis is 149mm, the nozzle length is 46mm, the nozzle outer circle is φ50mm, and the nozzle inner hole is φ26mm. R angle thickness ~ 7mm; the length of the tube blank for spinning is 1305mm, the inner diameter is 404mm, and the wall thickness is 7.6mm. The tube blank is annealed before the closing spinning. The system is 350℃, 1h, and air cooling. The following is the specific process of precision necking spinning forming:

[0039] Step (1): Mount the 6061 aluminum alloy cylindrical tube blank on the fixture of the special closing spinning equipment, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com