Anal fistula thread of three-dimensional composite structure and preparation method of anal fistula thread

A three-dimensional composite, anal fistula technology, applied in the fields of medical science, textiles and papermaking, surgery, etc., can solve the problems of increasing patient pain, increasing the chance of infection, easily causing anal incontinence, etc., to shorten the operation time and frequency, reduce difficulty and side effects , easy to learn and promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

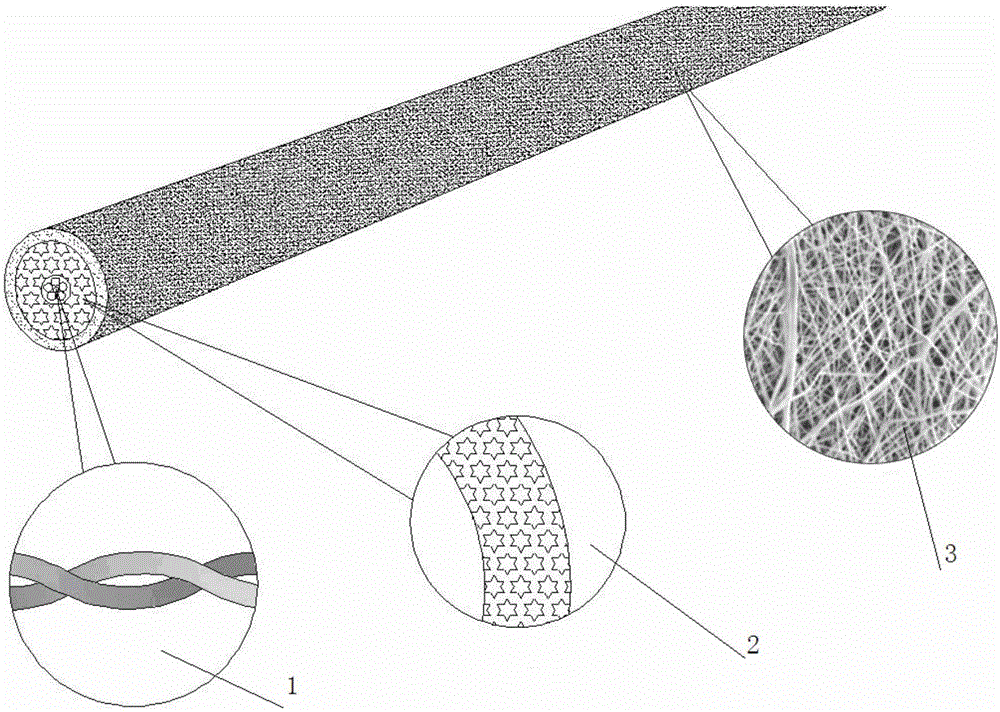

[0034] Embodiment 1: A three-dimensional composite structure anal fistula thread. The anal fistula line has a three-layer structure, which are:

[0035] The innermost layer 1 is more than two strands of hollow filament braided wire that can provide good flexibility and mechanical strength, which is convenient for traction and position correction during implantation.

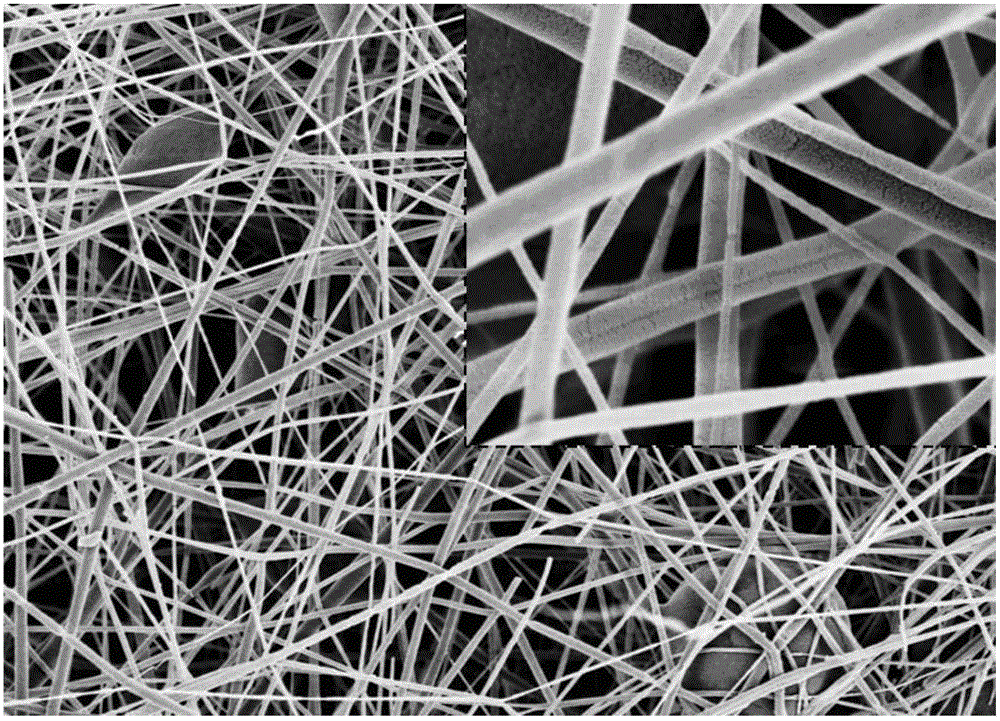

[0036]The middle layer 2 is a superfine fiber-based structural layer, and the fibers in this layer have the characteristics of sea-island cross-section, moderate fluffiness, good fiber orientation, and orderly arrangement. The middle layer is a collection of fiber bundles, and the index of bulkiness is represented by fiber filling density, and the filling density of superfine fibers in the middle layer is 50-80±2kg / m 3 , If the filling density is too high, the drainage resistance will be large, and the drainage effect cannot be achieved; if the filling density is too small, the middle layer will be loose, and th...

Embodiment 2

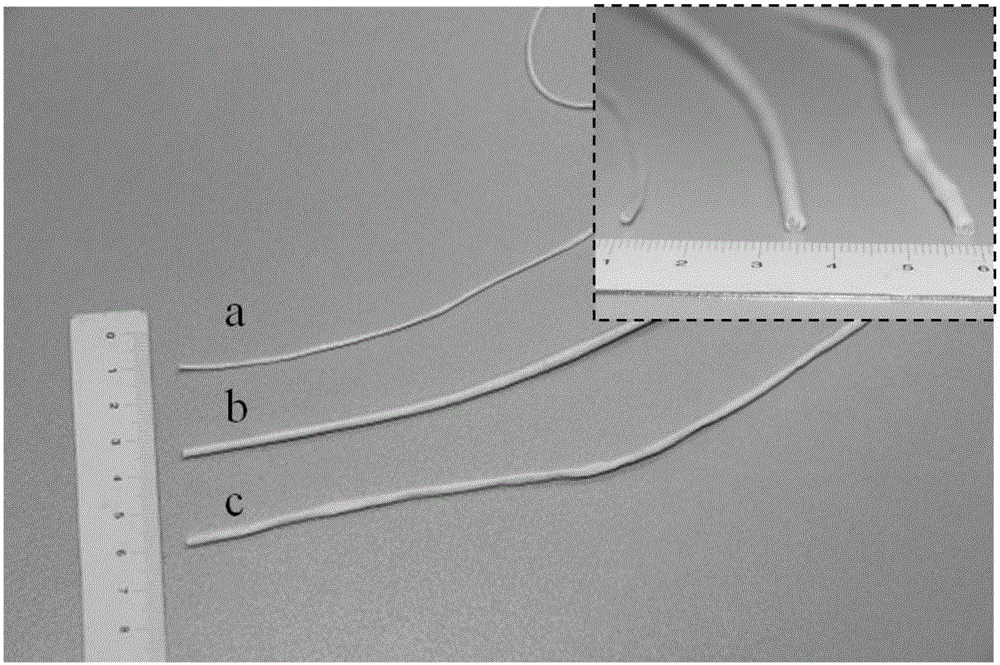

[0039] A kind of three-dimensional composite structure anal fistula thread, which adopts braiding method to prepare the inner (core) layer of the anal fistula thread: in this embodiment, the inner layer of the anal fistula thread adopts two or more strands of braided thread, which is a hollow fiber filament with a circular cross section. It is woven by a vertical spindle type circular knitting machine. The weaving process is as follows: 8-24 spindle vertical knitting machines are used, respectively according to the three structures of diamond weaving (1 / 1 interweaving), regular weaving (2 / 2 interweaving) and Hercules (3 / 3 interweaving). The braiding angle is 45-60°. Then, place the braided wire in a vacuum oven at 80±2°C for heat setting for 30 minutes. The hollow fiber filament has a hollowness of 18-36%, a filament linear density of 100-200dtex, and the raw material is L-polylactide (PLLA). The tensile strength of the hollow fiber filament braided wire obtained in this emb...

Embodiment 3

[0043] A three-dimensional composite structure anal fistula thread, the inner (core) layer of the anal fistula thread is prepared by the method of parallel arrangement of filaments, in this embodiment, the inner layer of the anal fistula thread adopts two or more parallel arrangement threads, which are hollow fibers with a circular cross section filament. Then, soak the hollow fiber filaments in 5-20% silk fibroin aqueous solution for 3-10s, put them in a vacuum oven at 80±2°C for heat setting for 30-60 minutes, and repeat the above operation three times. The hollow fiber filament has a hollowness of 18-36%, a filament linear density of 100-200dtex, and a raw material of polydioxanone (PDO). The tensile strength of the hollow fiber filament braided wire obtained in this embodiment is greater than 400N / mm 2 , The breaking strength is greater than 600MPa, the melting temperature is higher than 90°C, and the breaking elongation is less than 40%. Other options for hollow fiber f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com