A drum equipment for tobacco processing

A drum equipment, tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of sealing ring structure and high strength requirements, no static electricity removal device, welding strength influence, etc., to prevent dust explosion hazards, improve The reliability of equipment operation and the effect of not being easy to accumulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A kind of drum equipment for tobacco processing of the present invention is described in detail below in conjunction with accompanying drawing:

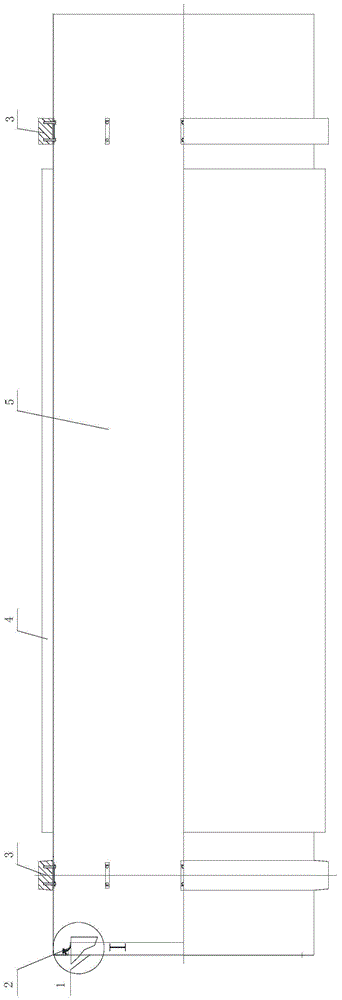

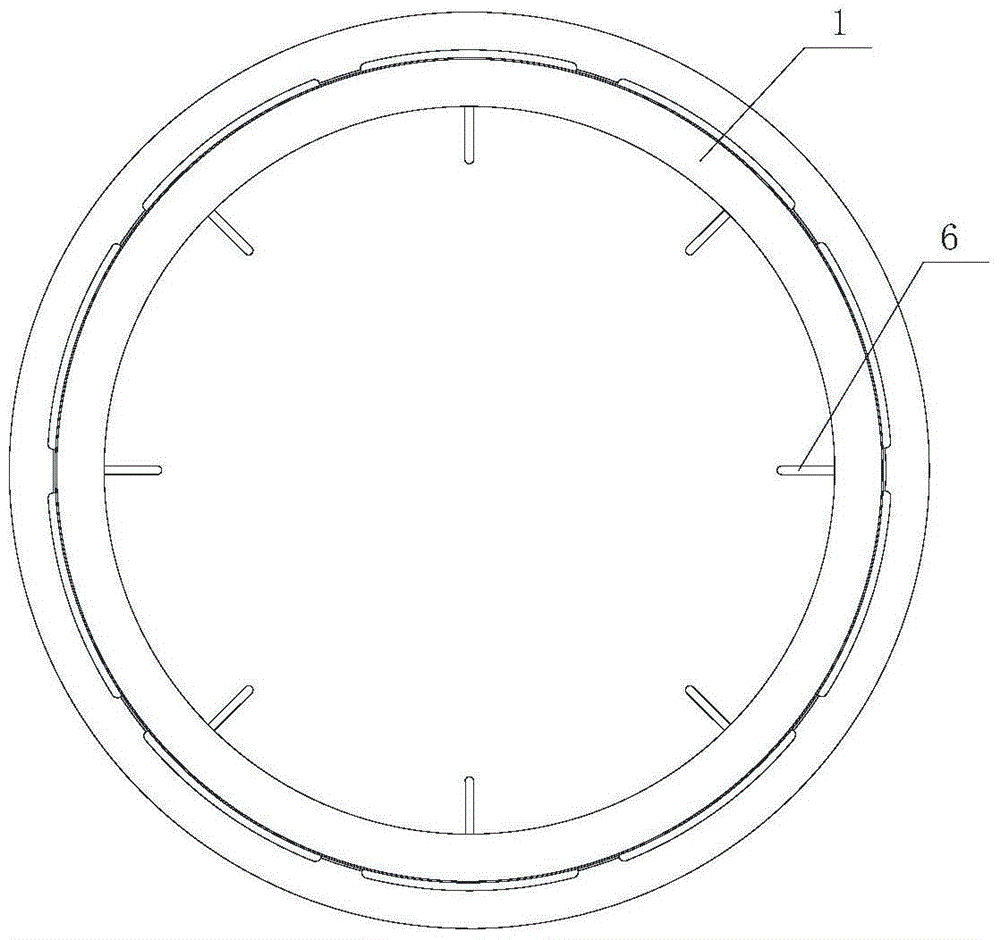

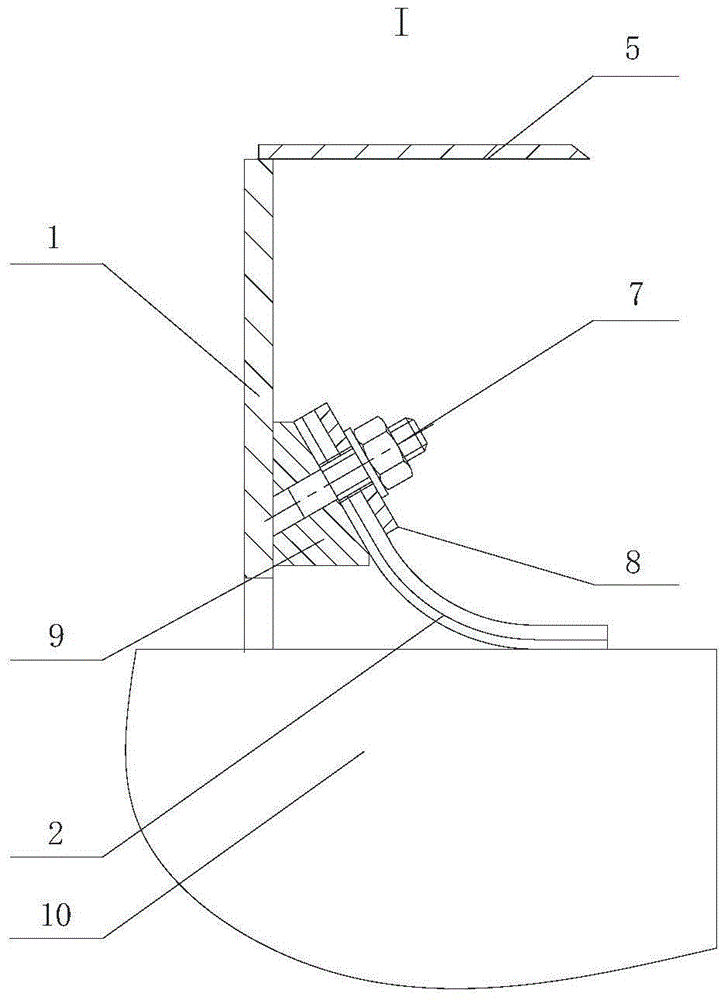

[0037] Such as Figure 4 As shown, a drum device for tobacco processing includes a drum for accommodating tobacco materials, the drum includes a cylinder 5, the cylinder 5 is a cylindrical structure, and the two ends of the cylindrical structure have openings, said The drum also includes a head 11, one end of the cylinder body 5 is open and fixedly connected to the head 11, and the end of the head 11 is provided with a feed port; The arc transition part 112.

[0038] The drum of the present invention is formed by a fixed connection between the cylinder body 5 and the head 11. Since the head 11 has a circular arc transition portion, the connection between the cylinder body 5 and the head 11 has a smooth transition, and it is not easy to accumulate tobacco materials. And easy to clean, to avoid "dead zone".

[0039] The cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com