Composite adhesive, preparation method thereof, lithium battery

A binder, lithium battery technology, used in battery electrodes, secondary batteries, circuits, etc., can solve the problems of cycle stability, rate performance capacity or unsatisfactory safety performance, and improve cycle stability performance, rate performance and safety performance. Excellent safety performance and easily controllable conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

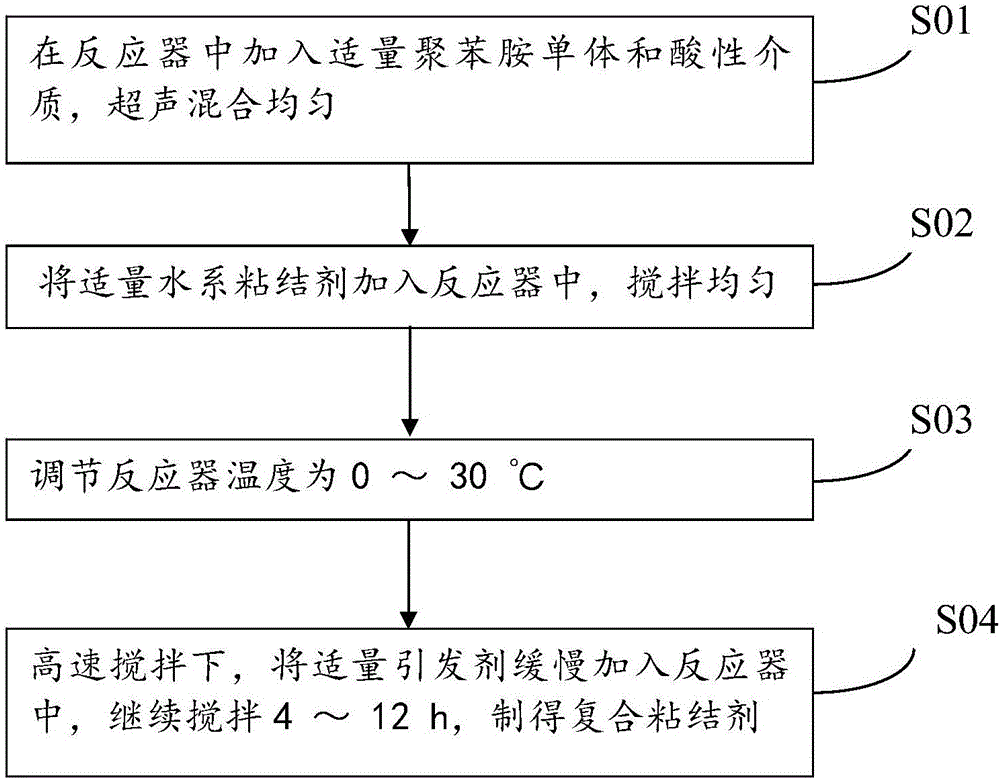

[0030] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned composite binder. The process flow of the composite binder preparation method is as follows: figure 1 As shown, it includes the following steps:

[0031] Step S01: mixing the conductive polymer monomer, the water-based binder and the acidic medium in proportion to prepare a mixed reaction solution;

[0032] Step S02: adjust the temperature of the mixed reaction solution prepared in step S01 to 0-30° C., and then add an initiator to carry out in-situ composite reaction until the completion, to obtain the composite binder.

[0033] Specifically, the conductive polymer monomer, water-based binder and acidic medium in the above step S01 and the selected type of water-based binder in the step S02 are all the same as the conductive polymer monomer described above in the composite binder. , water-based binder and acidic medium, in order to save space, no more de...

Embodiment 1

[0047] A polyaniline / polyacrylic acid composite binder and a preparation method thereof. The preparation method of polyaniline / polyacrylic acid composite binder comprises the following specific steps:

[0048] S11: Add 2g of polyaniline monomer and 50ml of 1M HCl into a three-necked flask, sonicate for 10min, and mix well;

[0049] S12: Weigh 8g of 25wt% polyacrylic acid aqueous solution, add it into a three-necked flask, and stir at 300rpm;

[0050] S13: Place the three-necked flask in an ice-water bath, and keep the temperature inside the flask at about 5°C;

[0051] S14: Slowly add ammonium persulfate aqueous solution (6.25gAPS dissolved in 50mlH 2 0), the rate of drop is 1 drop / second;

[0052] S15: Continue stirring and reacting for 12 hours to prepare a polyaniline / polyacrylic acid composite binder.

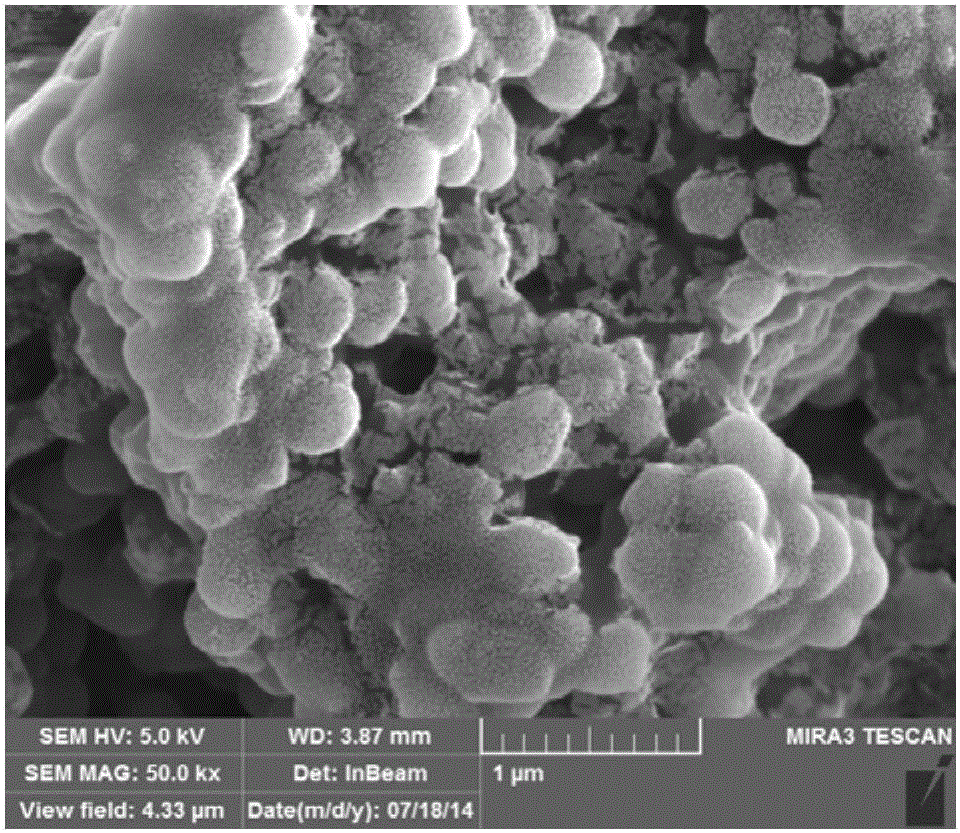

[0053] The polyaniline / polyacrylic acid composite binder prepared in embodiment 1 is carried out scanning electron microscope (SEM) analysis, scanning electron microsco...

Embodiment 2

[0055] A composite binder and a preparation method thereof. Composite binder preparation method comprises following specific steps:

[0056] S21: Add 0.2g of polyaniline monomer and 0.5g of 50wt% phytic acid aqueous solution into the sample bottle, sonicate for 10min, and mix well;

[0057] S22: Weigh 0.8g of 25wt% polyacrylic acid aqueous solution, add it to the sample bottle, and stir at 300 rpm;

[0058] S23: Weigh 1.6g of nano-silicon, add it into the sample bottle, and adjust the solid content of the slurry to about 35%;

[0059] S24: Slowly add 0.09g initiator ammonium persulfate to the sample bottle;

[0060] S25: coating the adjusted slurry on the copper foil, and drying in vacuum at 60° C. to obtain a silicon-based negative electrode material electrode;

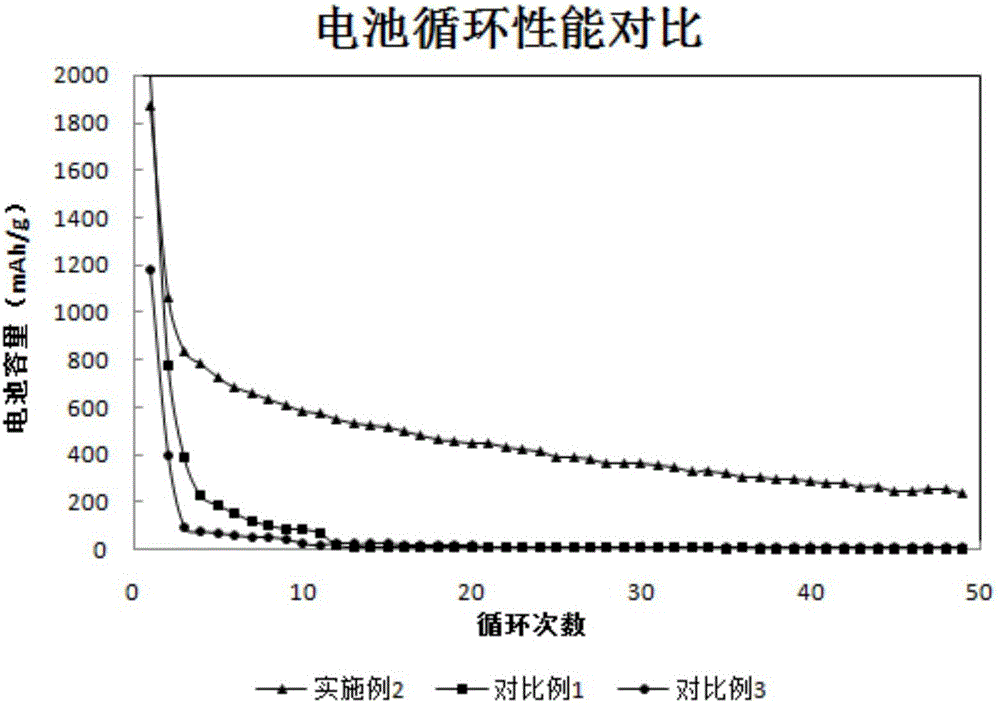

[0061] S26: The electrode prepared in S25 is used as the negative electrode, and the metal lithium sheet is used as the positive electrode, and assembled into a button battery, and the electrochemical performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com