Insulator airtightness detection system and method

A sealing detection and insulator technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problems of high production cost, large volume, cumbersome operation, etc., and achieve cost Low cost, good detection effect, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

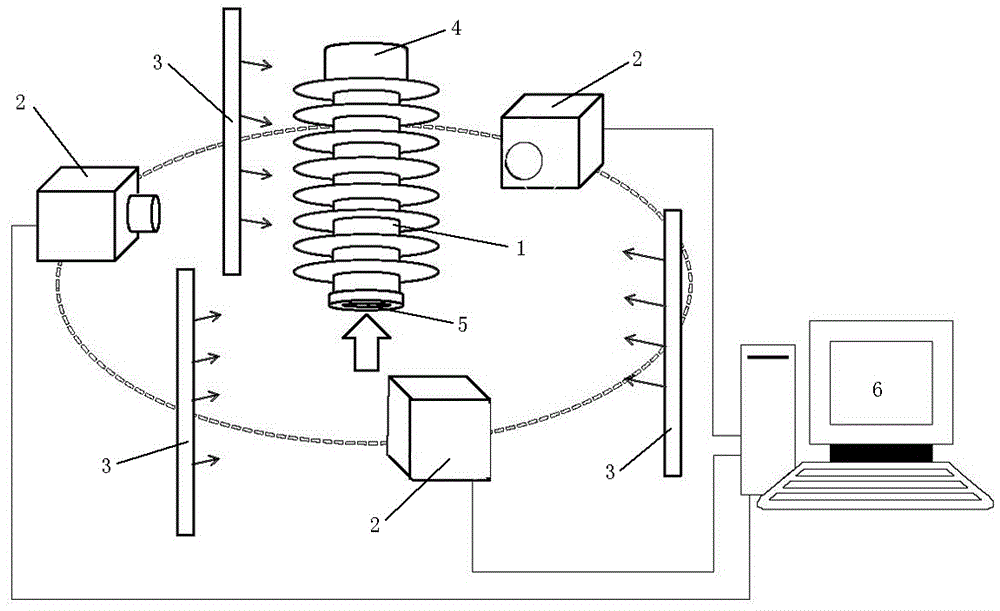

[0025] refer to figure 1 , an insulator airtightness detection system, comprising an insulator 1, a camera 2 and an ultraviolet light source 3, the cavity of the insulator 1 is passed with air with phosphor, the phosphor is evenly dispersed in the air, and the phosphor particles The diameter is 0.5 μm, and the phosphor is calcium orthophosphate [(Ca, Zn) 3 (PO 4 ) 2 : T1] fluorescent powder; the camera 2 and the ultraviolet light source 3 are distributed on the periphery of the insulator 1, and one end of the insulator 1 is sealed by a sealing cap 4, and the other end is provided with an air inlet 5, and the number of the camera 2 is three, It is evenly distributed along the periphery of the insulator 1, and the cameras 2 are respectively connected to the computer 6, which can realize multi-angle and all-round monitoring; the number of the ultraviolet light sources 3 is three, which are evenly distributed along the periphery of the insulator 1, and the cameras 2 and The ult...

Embodiment 2

[0027] refer to figure 1 , a method for detecting the tightness of an insulator, comprising the steps of:

[0028] (1) The phosphor powder is pulverized by jet milling method to obtain particles with a particle size of 0.2 μm, which are mixed with air to uniformly disperse the phosphor powder in the air. During the jet milling, the air pressure is controlled to be 0.72 MPa, and the fluorescent powder Powder is calcium orthophosphate [(Ca, Zn) 3 (PO 4 ) 2 : Tl〕 fluorescent powder;

[0029] (2) Pass high-pressure air with fluorescent powder through the air inlet 5 of the insulator 1;

[0030] (3) Under the irradiation of three ultraviolet light sources (ultraviolet light sources) 3, if there is colored fluorescence around the insulator, it is judged that there is air leakage, otherwise there is no air leakage; use three cameras 2 to take images of the insulator; among them, the three The cameras are evenly distributed along the periphery of the insulator, and are respective...

Embodiment 3

[0033] refer to figure 1 , an insulator airtightness detection system, comprising an insulator 1, a camera 2 and an ultraviolet light source 3, the cavity of the insulator 1 is passed with air with phosphor, the phosphor is evenly dispersed in the air, and the phosphor particles The diameter is 1.5 μm; the camera 2 and the ultraviolet light source 3 are distributed on the periphery of the insulator 1, one end of the insulator 1 is closed by a sealing cap 4, and the other end is provided with an air inlet 5, and the number of the cameras 2 is three, of which Evenly distributed along the periphery of the insulator 1, the cameras 2 are respectively connected to the computer 6, which can realize multi-angle and all-round monitoring; the number of the ultraviolet light sources 3 is three, which are evenly distributed along the periphery of the insulator 1, and the cameras 2 and ultraviolet The light source 3 is set at intervals, which can provide light sources from multiple angles ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com