Gas steam/hot water/boiled water three-heat-in-one stainless steel round tube and round liner heat exchanger

A gas steam and heat exchanger technology, which is applied in the field of food hygiene and safety production, can solve the problems of reduced heat exchange rate, high exhaust temperature, and increased waste heat discharge temperature, so as to reduce the coefficient of thermal expansion and contraction and reduce the exhaust temperature. , Improve the effect of fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

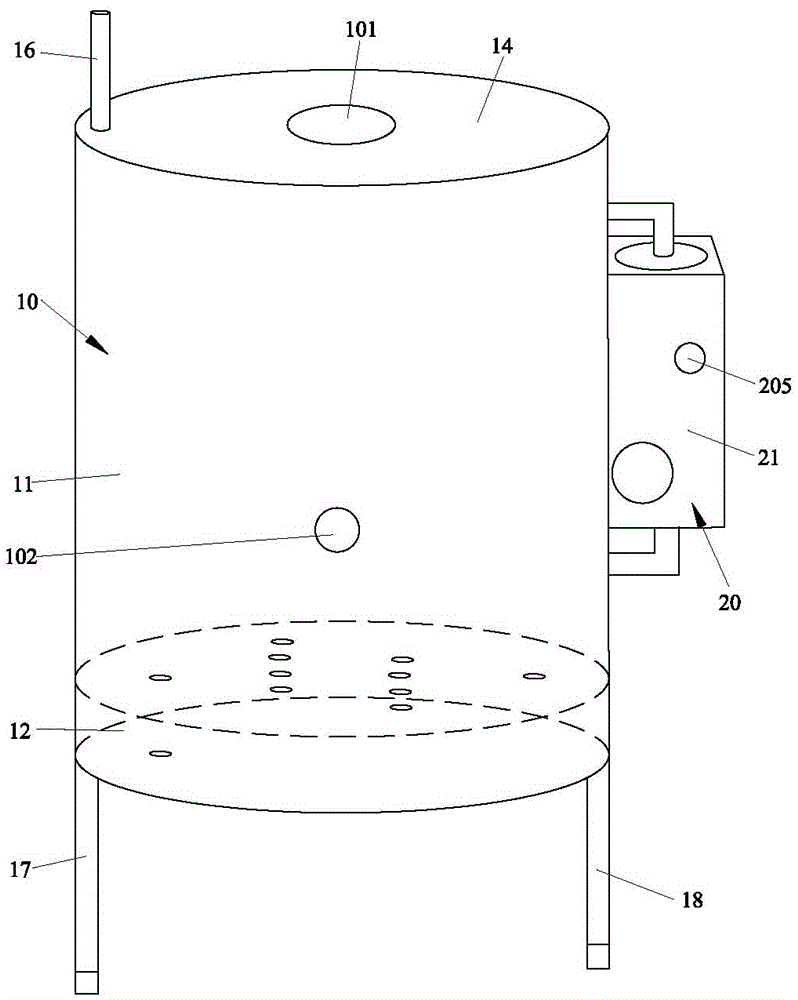

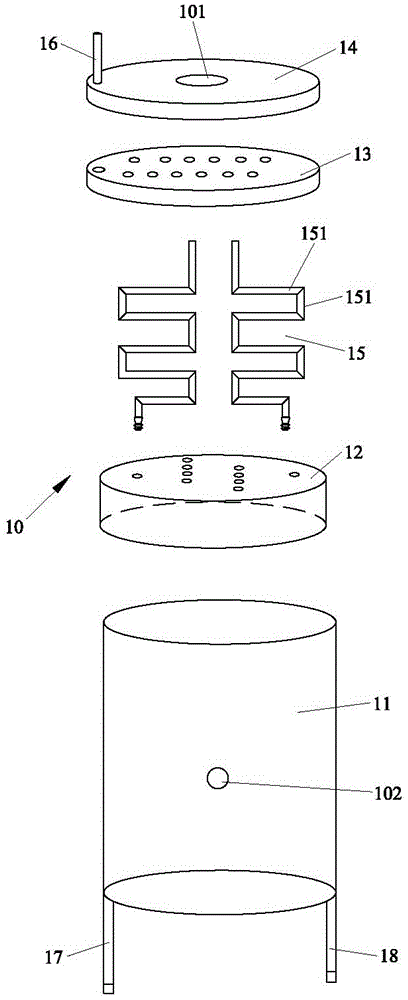

[0036] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the preferred embodiment of the present invention, including the main tank 10 and the automatic water inlet box 20.

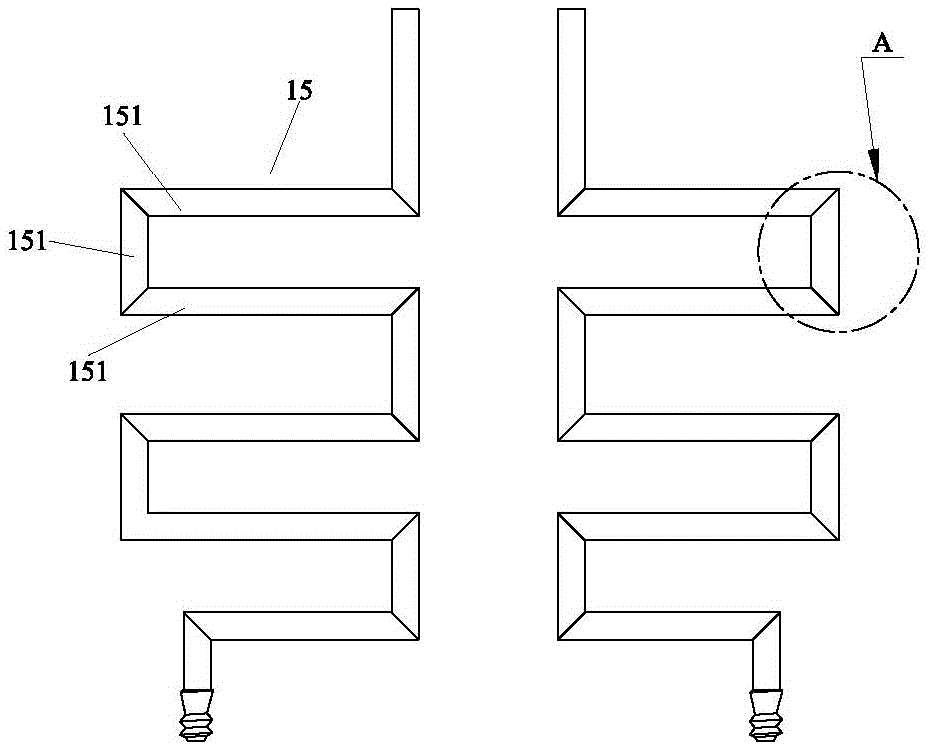

[0037] The main tank 10 includes a water tank 11, a combustion chamber 12, an upper plate 13, a cover plate 14, and a plurality of quick heat exchange tubes 15; the water tank 11 is in the shape of an upright round tank, which is made of a circular stainless steel plate ring. ; The combustion chamber 12 is arranged inside the bottom end of the water tub 11. In this embodiment, the combustion chamber 12 is circular, and its round edge is provided with a scale layer (not shown); the upper plate 13 and the cover Plate 14 is arranged on the inside of the top of water tub 11, forms water holding space (not shown in the figure) between this upper plate 13 and combustion chamber 12, and this cover plate 14 is positioned at the top of upper plate 13, and cover plate 14 and upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com