A kind of rolling piston for refrigeration compressor and its manufacturing method

A refrigeration compressor, rolling piston technology, applied in rotary piston/swing piston pump components, machines/engines, rotary piston pumps, etc., can solve the problems affecting the health of operators, complex manufacturing process and poor working environment and other problems, to achieve the effect of good processability, cost saving and low friction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

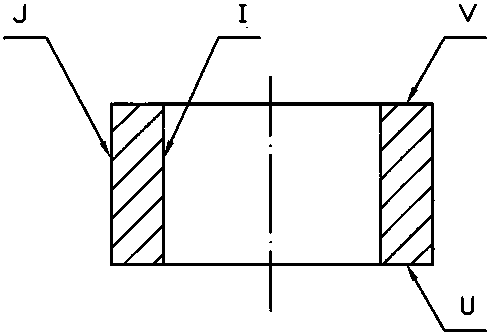

[0029] A rolling piston for a rotary refrigeration compressor, the piston material is a steel pipe after carburizing steel cold rolling.

[0030] The material of the rolling piston is steel pipe after carburizing steel cold rolling.

[0031] In this embodiment, the chemical composition of the carburized steel is as follows in % by weight: C0.17-0.23 Si0.17-0.37 Mn0.90-1.20 Cr0.90-1.20 Fe balance. Specifically: 20CrMn.

[0032] In another embodiment, the chemical composition of the above carburized steel is as follows by weight: C0.17-0.23 Si0.17-0.37 Mn0.80-1.10 Cr1.00-1.30 Ti 0.04-0.10 Fe balance. Specifically: 20CrMnTi.

[0033] A method for manufacturing a rolling piston for a rotary refrigeration compressor, comprising the steps of:

[0034] (1) Select carburized steel and cold roll it into a steel pipe that meets the precision require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com