A kind of polycrystalline diamond composite sheet and its application

A technology of polycrystalline diamond and composite sheet, which is applied to drilling equipment, earthwork drilling, drill bits, etc. It can solve the problems of difficult shaping, high hardness of cemented carbide, and strong wear resistance, which is beneficial to drilling speed and simplification. Manufacturing process, strong and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

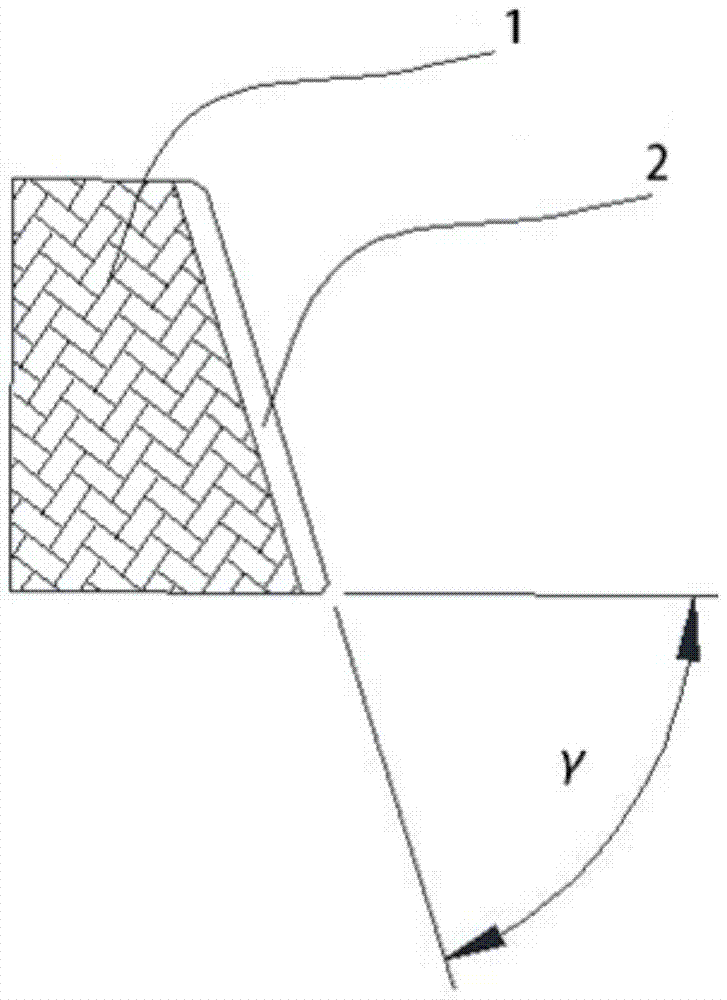

[0039] This embodiment provides a polycrystalline diamond compact, the schematic diagram of the polycrystalline diamond compact is as follows image 3 As shown, the polycrystalline diamond compact 4 includes a cemented carbide layer 1 and a polycrystalline diamond layer 2 . The composite interface of the polycrystalline diamond layer 2 and the cemented carbide layer 1 can be a plane or a concave-convex surface. The designed diameter of the polycrystalline diamond compact 4 is 16 mm, the thickness is 8 mm, and the included angle γ formed by the polycrystalline diamond layer 2 and the generatrices of the polycrystalline diamond compact 4 is 65°.

Embodiment 2

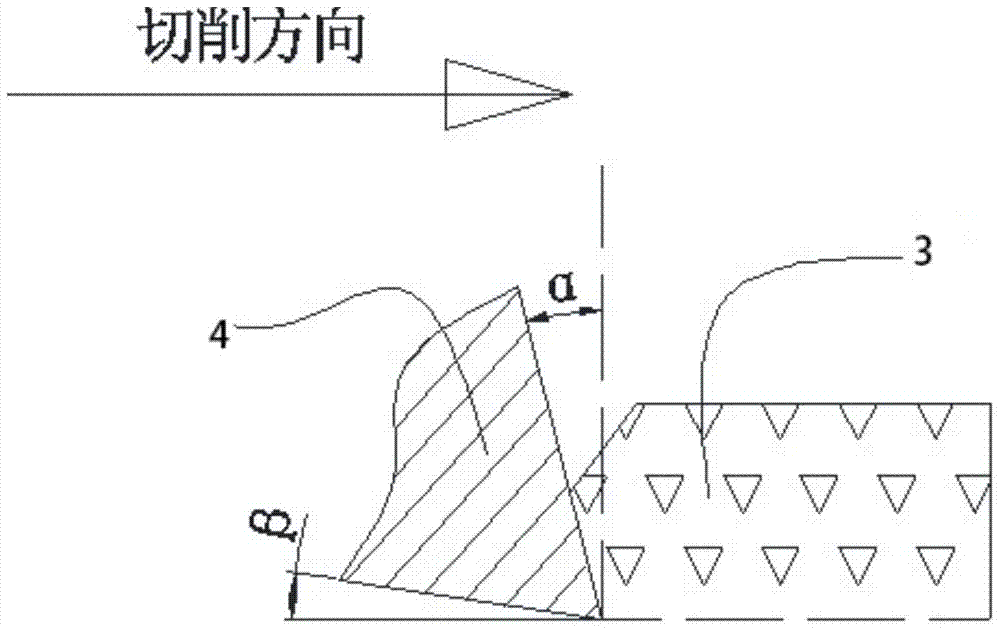

[0041] This embodiment provides the application of the polycrystalline diamond compact in embodiment 1 on a PDC drill bit. When the polycrystalline diamond compact 4 of Example 1 is applied to a PDC drill bit, when cutting the workpiece 3, the controllable backlash angle β is 10°, and the cutting angle α is 15°. The cutting schematic diagram is as follows Figure 4As shown, with this cutting structure, higher cutting efficiency can be obtained. In order to increase the durability of the polycrystalline diamond compact 4, it is recommended that the main part used for cutting be beveled at 0.4mm and 45°.

Embodiment 3

[0043] This embodiment provides a polycrystalline diamond composite sheet, the schematic diagram of the polycrystalline diamond composite sheet is as follows Figure 5 As shown, the polycrystalline diamond compact 4 includes a cemented carbide layer 1 and a polycrystalline diamond layer 2 . The design diameter of the polycrystalline diamond compact is 16mm, the thickness is 8mm, and the included angle γ formed by the polycrystalline diamond layer 2 and the bus bar of the polycrystalline diamond compact 4 is 80°; the above-mentioned polycrystalline diamond compact is applied to the PDC drill bit ,use Figure 6 The way to weld the composite sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com