Composite flame-retardant electric heating cigarette paper, and preparation method thereof

An electric heating cigarette, composite flame retardant technology, applied in special paper, inorganic compound addition, chemical instruments and methods, etc., can solve the problems of poor retorting effect of cut tobacco, affecting the evaluation effect of cigarettes, and generating harmful smoke components, etc. Short production time, rich smoke, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

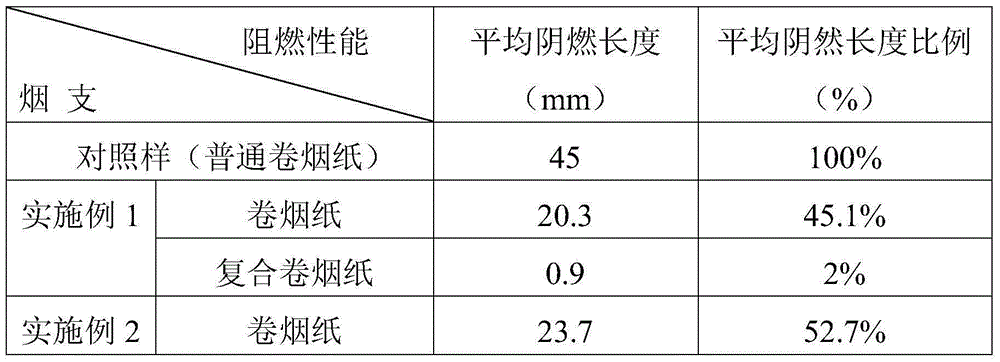

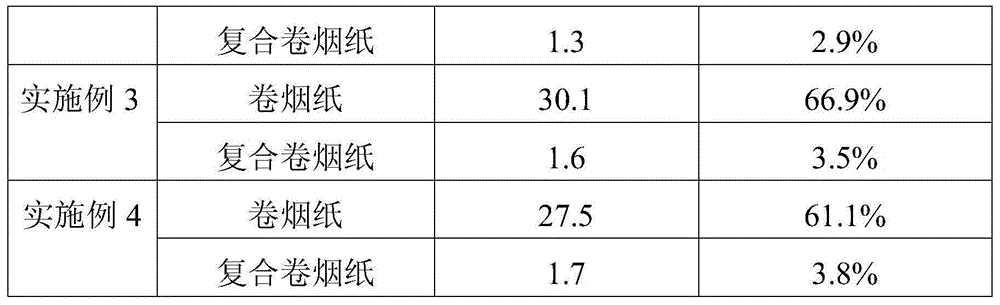

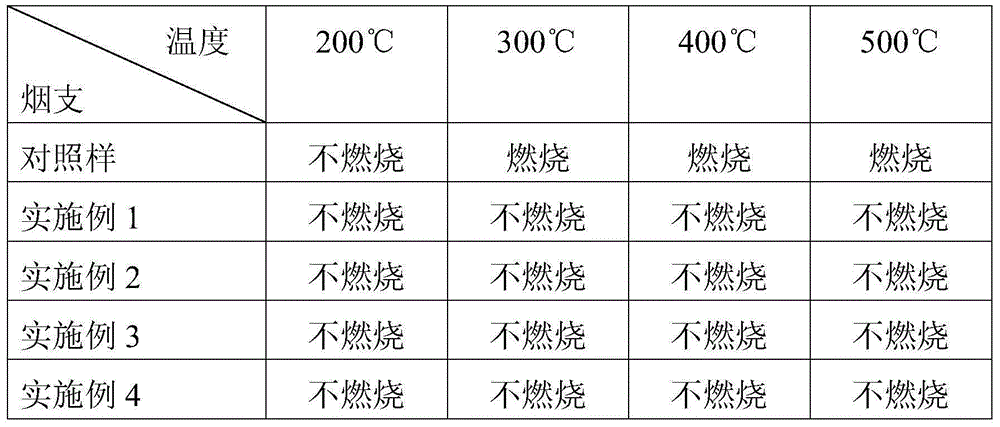

Examples

Embodiment 1

[0019] A composite flame-retardant electric heating cigarette paper, which is composed of cigarette paper and copper foil, the thickness of the copper foil is 40 μm, the thickness of the cigarette paper is 60 μm, and the cigarette paper is composed of the following weight ratio: Composition:

[0020] Cigarette paper fiber 70%, CaCO 3 15% of filler, 10% of flame retardant, 5% of guar gum, and the flame retardant is aluminum hydroxide.

[0021] The cigarette paper fibers are composed of tobacco fibers and wood pulp fibers, and the weight ratio of the tobacco fibers to the wood pulp fibers is 1:1.5.

[0022] The preparation method is:

[0023] Get tobacco fiber 28Kg, wood pulp fiber 42Kg, calcium carbonate filler 15Kg, aluminum hydroxide 10Kg, guar gum 5Kg, adopt known papermaking process to prepare into cigarette paper, then copper foil is compounded on the cigarette paper by adhesive acrylate On the one hand, the thickness of the copper foil is 40 μm, and the thickness of th...

Embodiment 2

[0025] A composite flame-retardant electric heating cigarette paper, which is composed of cigarette paper and aluminum foil, the thickness of the aluminum foil is 30 μm, the thickness of the cigarette paper is 70 μm, and the cigarette paper is composed of the following components by weight :

[0026] Cigarette paper fiber 65%, CaCO 3 25% of filler, 5% of flame retardant, 5% of guar gum, and the flame retardant is zinc borate.

[0027] The cigarette paper fibers are composed of tobacco fibers and wood pulp fibers, and the weight ratio of the tobacco fibers to the wood pulp fibers is 1:2.25.

[0028] The preparation method is:

[0029] Get 20Kg of tobacco fiber, 45Kg of wood pulp fiber, 25Kg of calcium carbonate filler, 5Kg of zinc borate, and 5Kg of guar gum, and prepare cigarette paper by using a known papermaking process, and then compound aluminum foil on the cigarette paper by adhesive polyvinyl acetate. On the one hand, the aluminum foil has a thickness of 30 μm, and th...

Embodiment 3

[0031] A composite flame-retardant electric heating cigarette paper, which is composed of cigarette paper and tin foil, the thickness of the tin foil is 55 μm, the thickness of the cigarette paper is 50 μm, and the cigarette paper is composed of the following components by weight :

[0032] Cigarette paper fiber 75%, CaCO 3 15% of filler, 3% of flame retardant, and 7% of guar gum. The flame retardant is a mixture of magnesium hydroxide and antimony trioxide, and the ratio of the two is 1:1.

[0033] The cigarette paper fiber is wood pulp fiber.

[0034] The preparation method is:

[0035] Get wood pulp fiber 75Kg, calcium carbonate filler 15Kg, magnesium hydroxide 1.5Kg, antimony trioxide 1.5Kg, guar gum 7Kg, adopt known papermaking process to prepare into cigarette paper, then pass tinfoil by adhesive polyvinyl acetate Composite on one side of the cigarette paper, the thickness of the tin foil is 55 μm, and the thickness of the cigarette paper is 50 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com