Low-temperature electrolysis of sio using ionic liquids 2 Method for preparing high-purity silicon thin film

A technology of ionic liquid and silicon thin film, which is applied in the field of materials, can solve problems such as poor conductivity, high process energy consumption, and slow reduction rate, and achieve the effects of reducing the thickness of silicon wafers, shortening the process flow, and reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

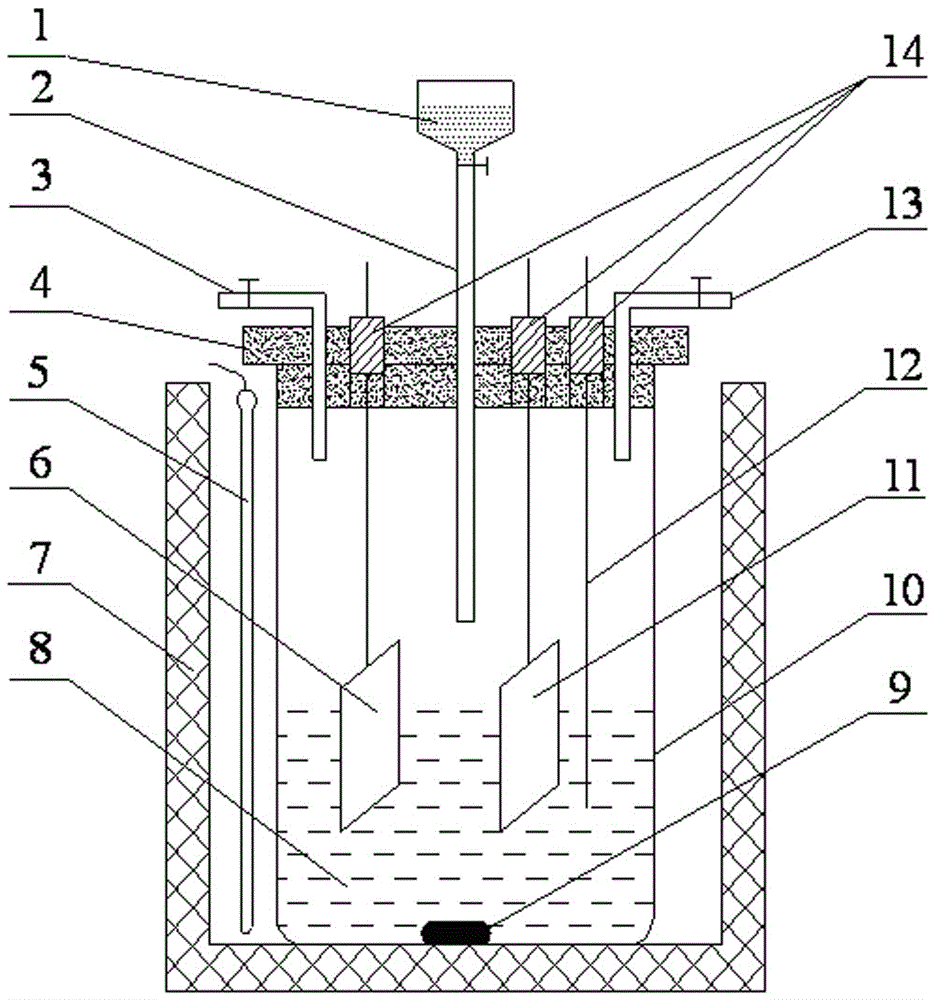

[0047] Low-temperature electrolysis of SiO using ionic liquids 2 The structure of the high-purity silicon thin film device is as follows: figure 1 As shown, the electrolytic cell 10 comprising the electric heating jacket 7 and its inside; the electric heating jacket 7 is provided with a thermocouple 5, and the electrolytic cell cover 4 on the top of the electrolytic cell 10 is provided with an inert gas inlet 3 and an inert gas outlet 13; The inside of the tank 10 is provided with a working electrode 6, a counter electrode 11 and a reference electrode 12, and the guide rods of the working electrode 6, the counter electrode 11 and the reference electrode 12 are respectively inserted into the rubber plugs 14 that have been drilled, and then inserted into the electrolytic cell cover. 4, forming a whole, inserted into the inside of the electrolytic cell 10; the top of the electrolytic cell 10 is also provided with a feeder 2, the feeder 2 is filled with silicon dioxide 1, and the ...

Embodiment 2

[0056] Device structure is with embodiment 1, and method is with embodiment 1, and difference is:

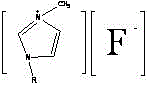

[0057] (1) Prepare the raw materials of the electrolyte. The raw materials of the electrolyte are fluorinated imidazolium ionic liquid, cryolite, hydrofluoric acid solution and silicon dioxide, of which fluorinated imidazolium ionic liquid accounts for 96% of the total mass of the electrolyte, and cryolite accounts for the total mass of the electrolyte 1%, silicon dioxide accounts for 1.5% of the total mass of the electrolyte, and hydrofluoric acid solution accounts for 1.5% of the total mass of the electrolyte; the fluorinated imidazole ionic liquid is 1-ethyl-3-methyl fluorinated imidazole;

[0058] (2) Control the electrolyte temperature at 20°C and control the current density at 20mA / cm 2 ; The pole spacing between the working electrode and the counter electrode is 25mm; the effective area S of the working electrode is 200cm 2 ;

[0059] (3) During the electrolysis process...

Embodiment 3

[0063] Device structure is with embodiment 1, and method is with embodiment 1, and difference is:

[0064] (1) Prepare the raw materials of the electrolyte. The raw materials of the electrolyte are fluorinated imidazolium ionic liquid, cryolite, hydrofluoric acid solution and silicon dioxide, of which fluorinated imidazolium ionic liquid accounts for 97% of the total mass of the electrolyte, and cryolite accounts for the total mass of the electrolyte 0.5%, silicon dioxide accounts for 1% of the total mass of the electrolyte, hydrofluoric acid solution accounts for 1.5% of the total mass of the electrolyte; the fluorinated imidazolium ionic liquid is 1-propyl-3-methylimidazolium fluoride;

[0065] (2) Control the electrolyte temperature at 85°C and control the current density at 80mA / cm 2 ; The pole spacing between the working electrode and the counter electrode is 15mm; the effective area S of the working electrode is 200cm 2 ;

[0066] (3) During the electrolysis process, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com