A brazing method for ceramics and metals or ceramics and ceramics

A brazing method and ceramic technology, applied in the field of ceramic/metal and ceramic/ceramic brazing, can solve problems such as cracks, rectangular groove stress concentration, lack of connection process methods, etc., to reduce costs, alleviate stress concentration, reduce Effect of residual thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

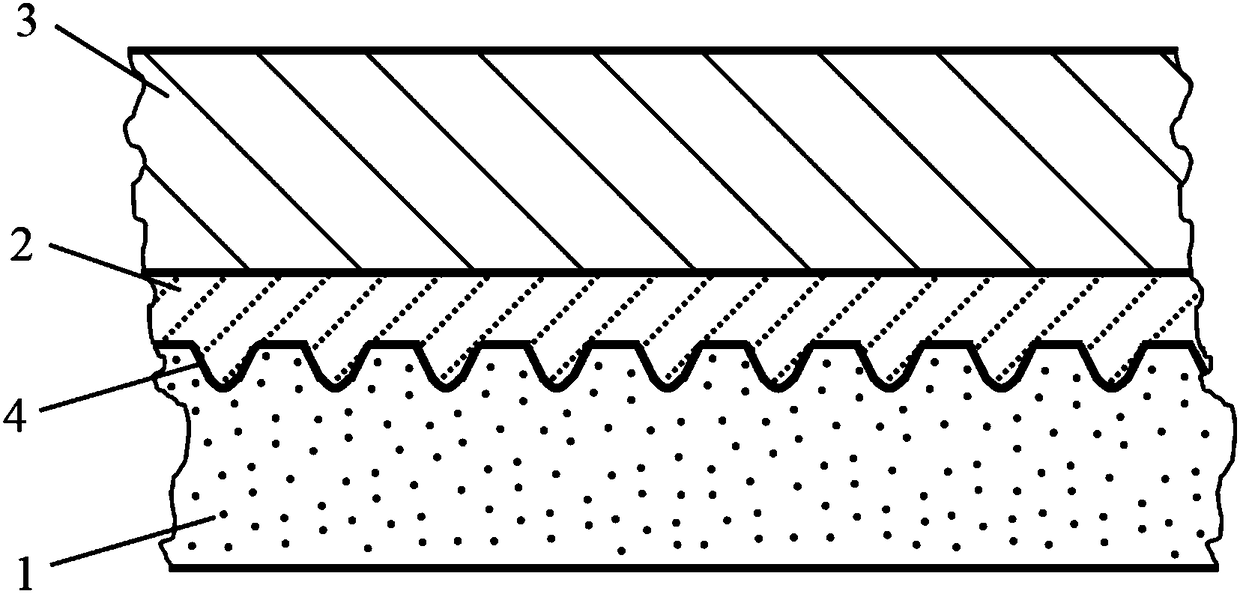

[0039] Such as figure 1 shown in Al 2 o 3 Through-shaped open grooves 4 are processed on the surface of the ceramic 1. The width of the open grooves 4 is 10 μm, the depth of the open grooves 4 is 10 μm, and the interval between the open grooves is 40 μm. The smooth transition between the two walls of the opening groove and the lower part is narrowed, and its cross-section is "U"-shaped.

[0040] Next, directly on the Al to be welded 2 o 3 The interface between ceramic surface 1 and metal material 3 is placed with AgCu-Ti active solder foil 2 after ultrasonic cleaning and drying, the metal material 3 is 304 stainless steel, and the content of Ti in the AgCu-Ti active solder foil is 2wt. %, the thickness is 30 μm;

[0041] Carry out vacuum brazing in the furnace, the brazing temperature is 900°C, and the vacuum degree is not lower than 2×10 -2 Pa, keep warm for 10 minutes, control the cooling rate at 10°C / min, and cool to room temperature, that is, the 10mm×10mm Al 2 o 3...

Embodiment 2

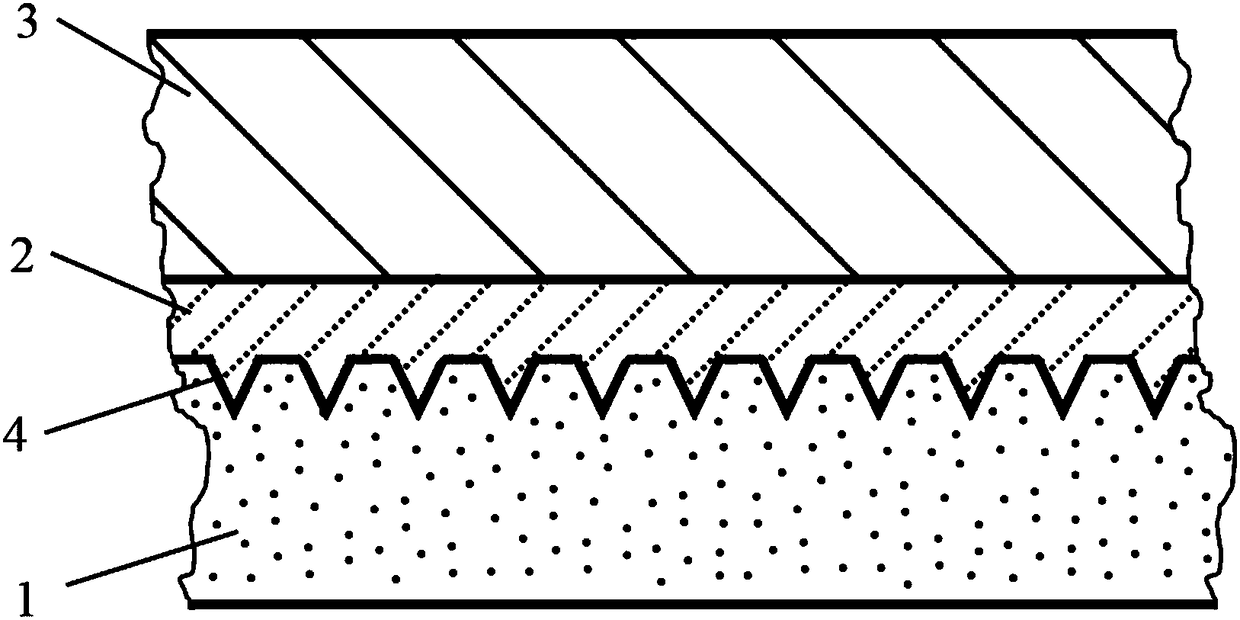

[0043] Such as Figure 6 As shown, on both sides Al 2 o 3 The surface of the ceramic 1 is processed with through opening grooves 4, the width of the opening grooves 4 is 200 μm, the depth of the opening grooves 4 is 200 μm, and the interval between the opening grooves is 1000 μm. The smooth transition between the two walls and the bottom of the opening groove narrows, and its cross section is nearly semicircular, quadrilateral, "U" or "V".

[0044] Next, directly on the Al to be welded 2 o 3 An AgCu-Ti active solder foil 2 that has been ultrasonically cleaned and dried is placed between the surfaces of the ceramic 1. The content of Ti in the AgCu-Ti active solder foil is 2.0wt.%, and the thickness is 400 μm.

[0045] Carry out vacuum brazing in the furnace, the brazing temperature is 900°C, and the vacuum degree is not lower than 2×10 -2 Pa, keep warm for 10 minutes, control the cooling rate at 10°C / min, and cool to room temperature, that is, the 10mm×10mm Al 2 o 3 Cera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com